Method for improving efficiency for carrying concrete

A concrete and high-efficiency technology, applied in the direction of container handles, etc., can solve the problems of troublesome carrying and repeated use of handles, and achieve the effect of facilitating repeated use, improving the efficiency of concrete handling, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

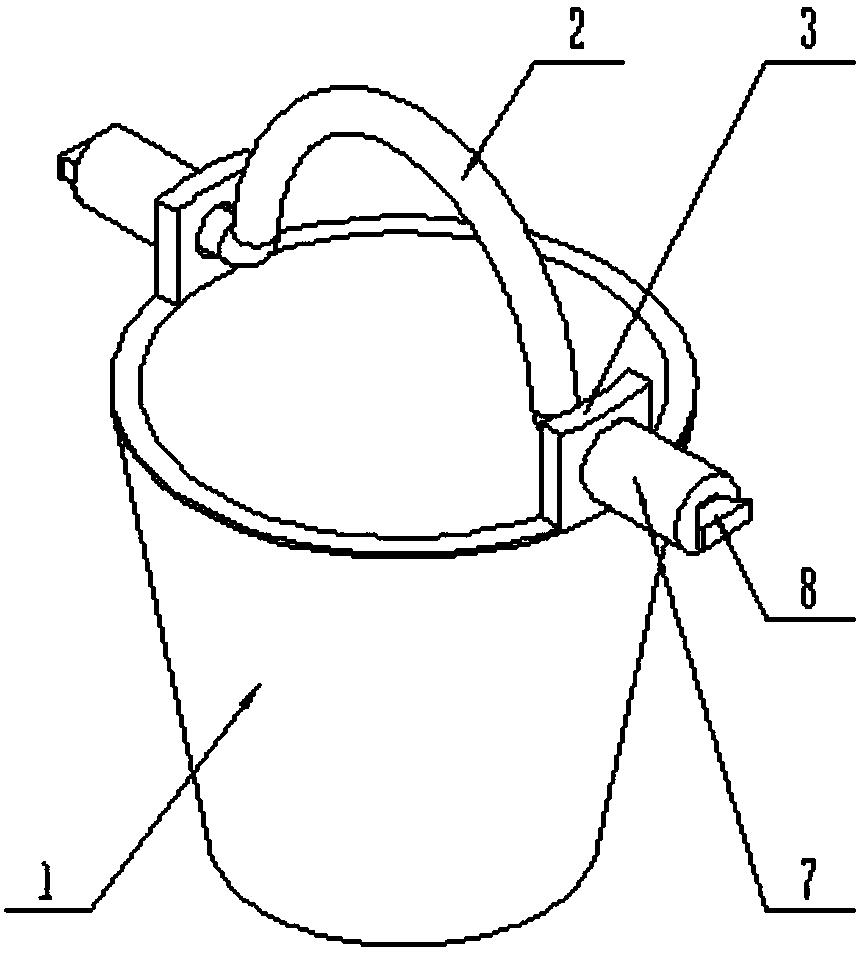

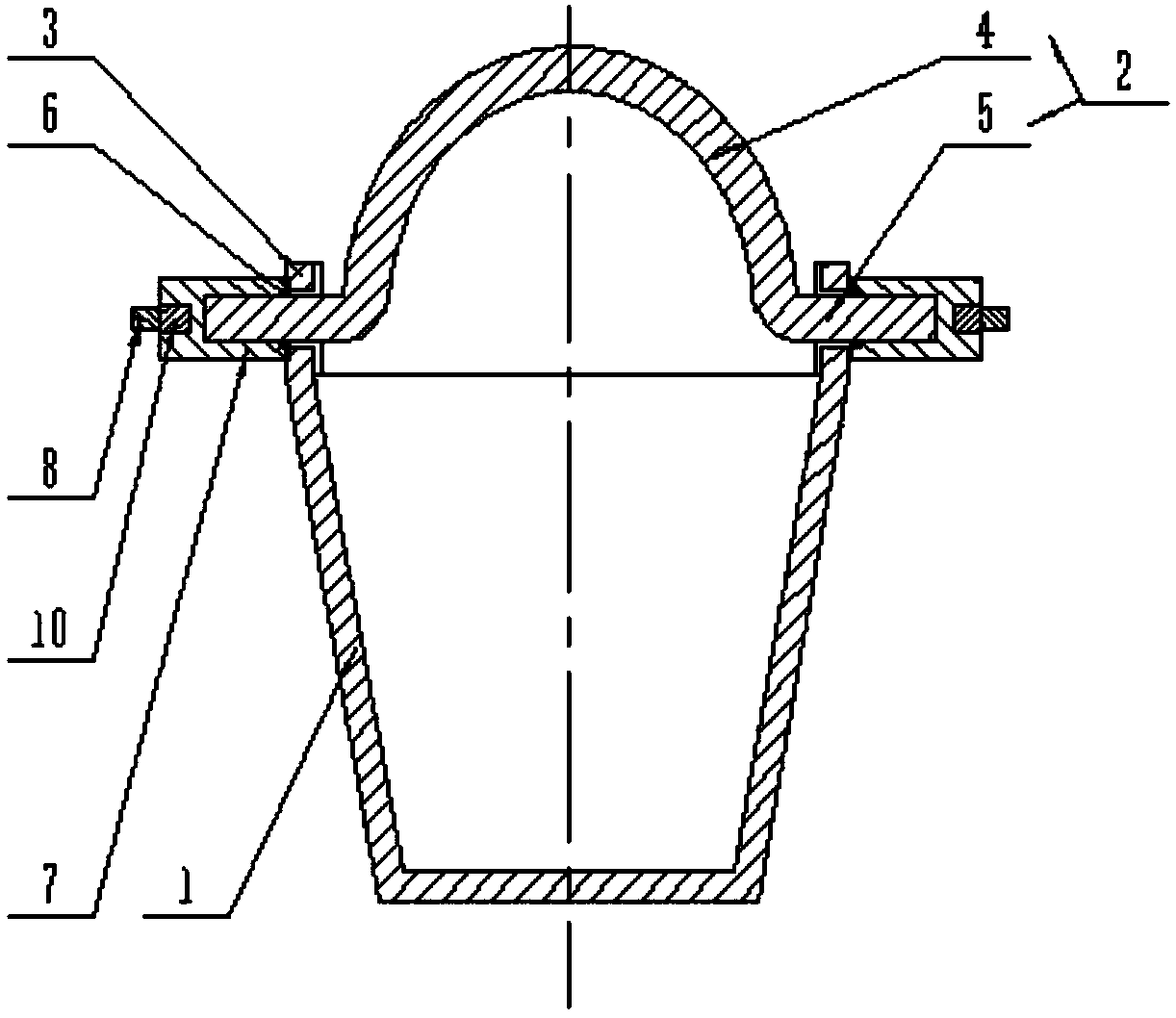

[0035] Such as Figure 1-Figure 5 Shown, the present invention improves the method for concrete handling efficiency, comprises the steps:

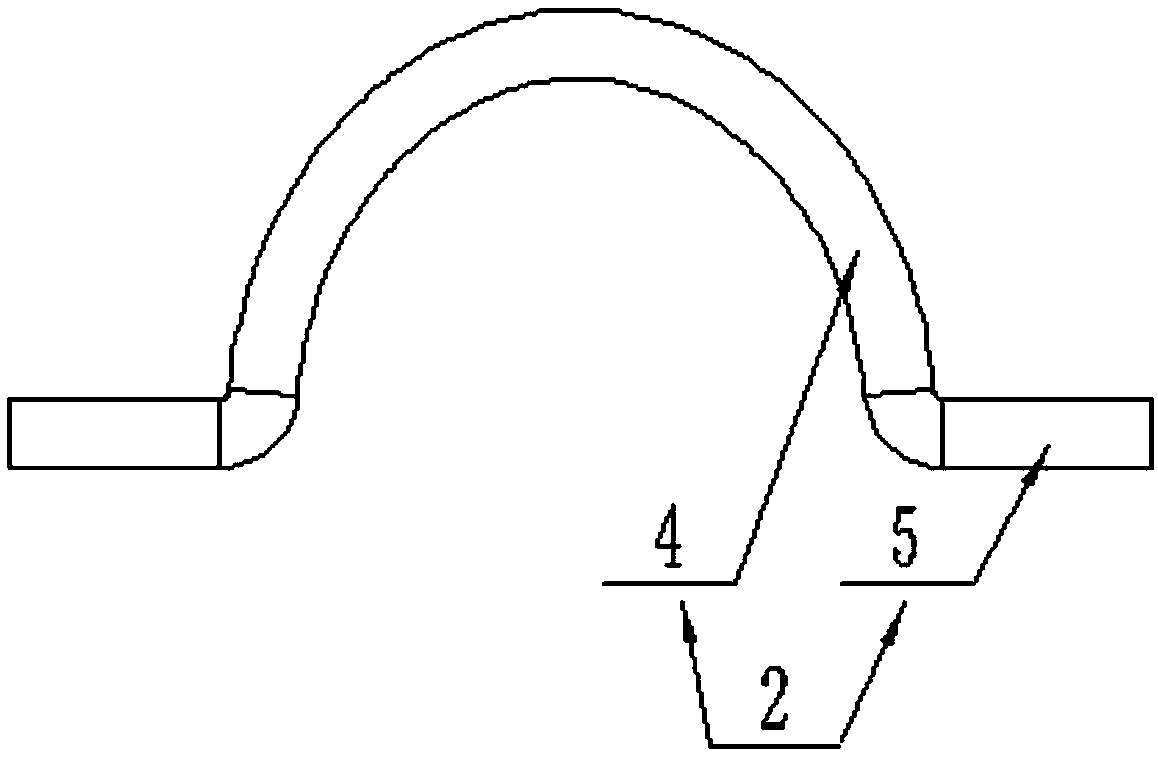

[0036] Step A: Pass the screw rods 5 at both ends of the connecting bar 4 in the handle 2 through the lugs 3 on the top of the barrel body 1 respectively;

[0037] Step B: Insert the screw rod 5 into the corresponding internal thread barrel 7 after passing through a sealing ring 6 respectively;

[0038] Step C: Insert the connecting shaft 10 into the connecting hole 9;

[0039] Step D: Rotate the rotating plate 8 to thread the internally threaded barrel 7 to the screw 5;

[0040] Step E: Pour concrete into barrel body 1 .

[0041] Prevent the end of the handle from slipping out of the lug by rolling the end of the traditional handle into a hook lock and change it to a limit assembly designed to match the end of the handle in the present invention. The limit assembly in the present invention and the handle Connecting the 2 threads will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com