A fastener striking tool

A technology for striking tools and fasteners, which is applied in the direction of manufacturing tools and nailing tools, and can solve problems such as potential safety hazards, complex structures of elastic meshing parts, and damage to transmission parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

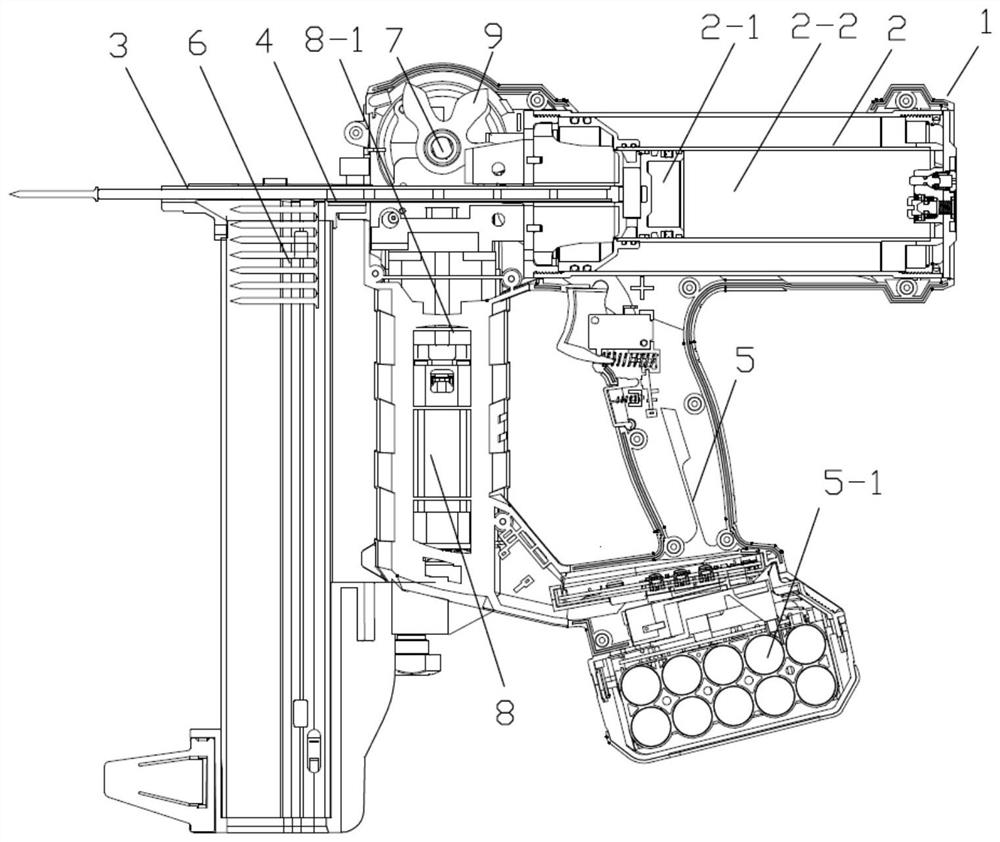

[0041] The basic structure of the fastener percussion tool in this embodiment can be found in image 3 The rear end of the housing 1 is equipped with an energy storage mechanism 2 composed of a cylinder 2-2 and a piston 2-1, and the piston 2-1 is fixedly connected with the firing pin 4 extending to the gun mouth 3. The lower side of the cylinder body 2-2 is provided with a handle 5 with a battery pack 5-1, the lower side of the gun nozzle 3 is provided with a nail box 6 for arranging nails, and a nail box 6 located between the handle 5 and the nail box 6 is provided on the top. The lifting mechanism 7 and the motor 8 and the reduction transmission mechanism 8-1 that are positioned at the bottom.

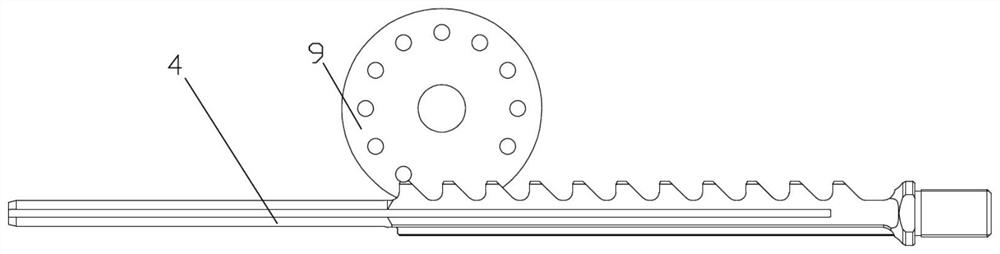

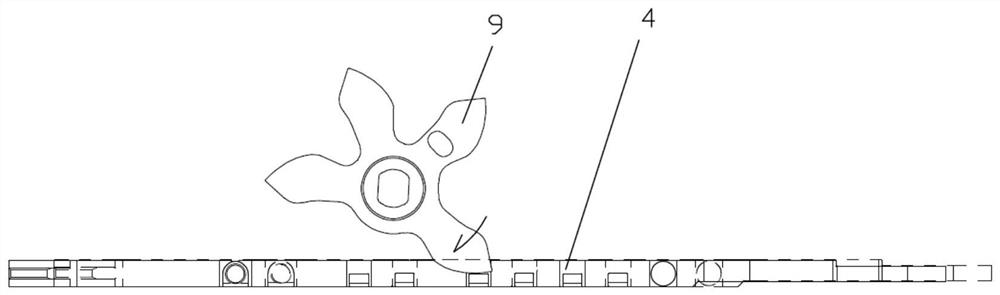

[0042] The concrete structure of hoisting mechanism 7 is as Figure 4 As shown, similar to the prior art, the lack of teeth that contains the clip gear structure that can force the striker 4 to move the compression piston 2-1 gives way to the drive wheel 9, and the axle of the drive...

Embodiment 2

[0050] The basic structure of the fastener percussion tool of this embodiment is the same as that of Embodiment 1, except that the rear end of the housing 1 is equipped with an energy storage mechanism 2, the piston 2-1 is fixedly connected with the firing pin 4 extending to the gun mouth 3, and the cylinder body 2 The underside of -2 is provided with a handle 5, the underside of the gun nozzle 3 is provided with a nail case 6, and between the handle 5 and the nail case 6 is provided with a lifting mechanism 7, a motor 8 and a reduction transmission mechanism 8-1; The lifting mechanism 7 contains a driving wheel that can force the striker to move and compress the piston 2-1 with missing teeth, and the axle of the driving wheel is connected with the motor 8 that the battery pack 5-1 provides electric energy through the reduction transmission mechanism 8-1.

[0051] Such as Figure 11 As shown, what has changed is that the tooth-missing relief drive wheel is a tooth-to-pin struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com