Circular grating eccentricity parameter calibration method of flexible arm coordinate measuring machine

A coordinate measuring machine and parameter calibration technology, applied in the field of precision measurement, can solve problems such as difficult on-site operation, and achieve the effects of convenient operation, fast convergence speed and high calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

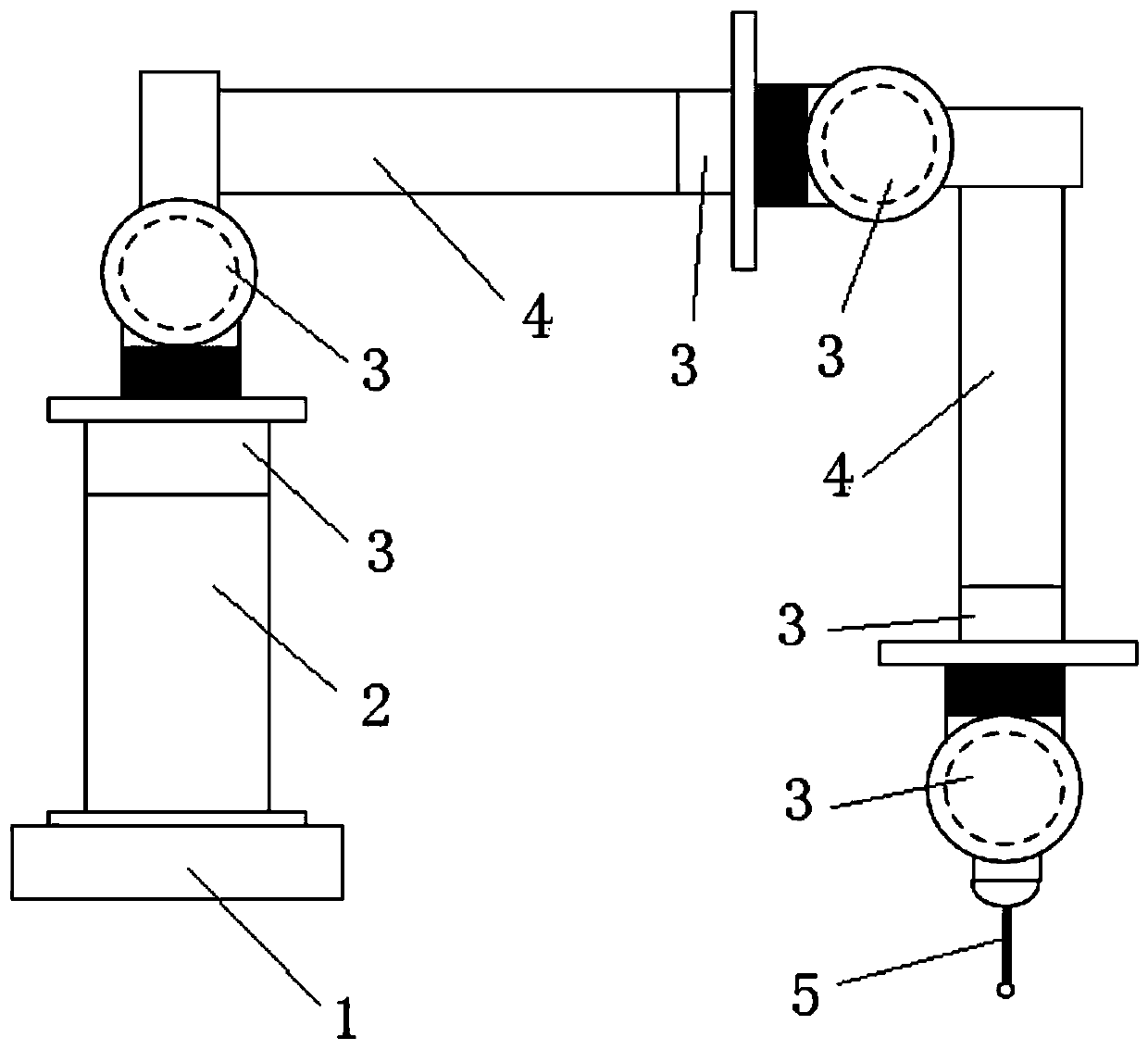

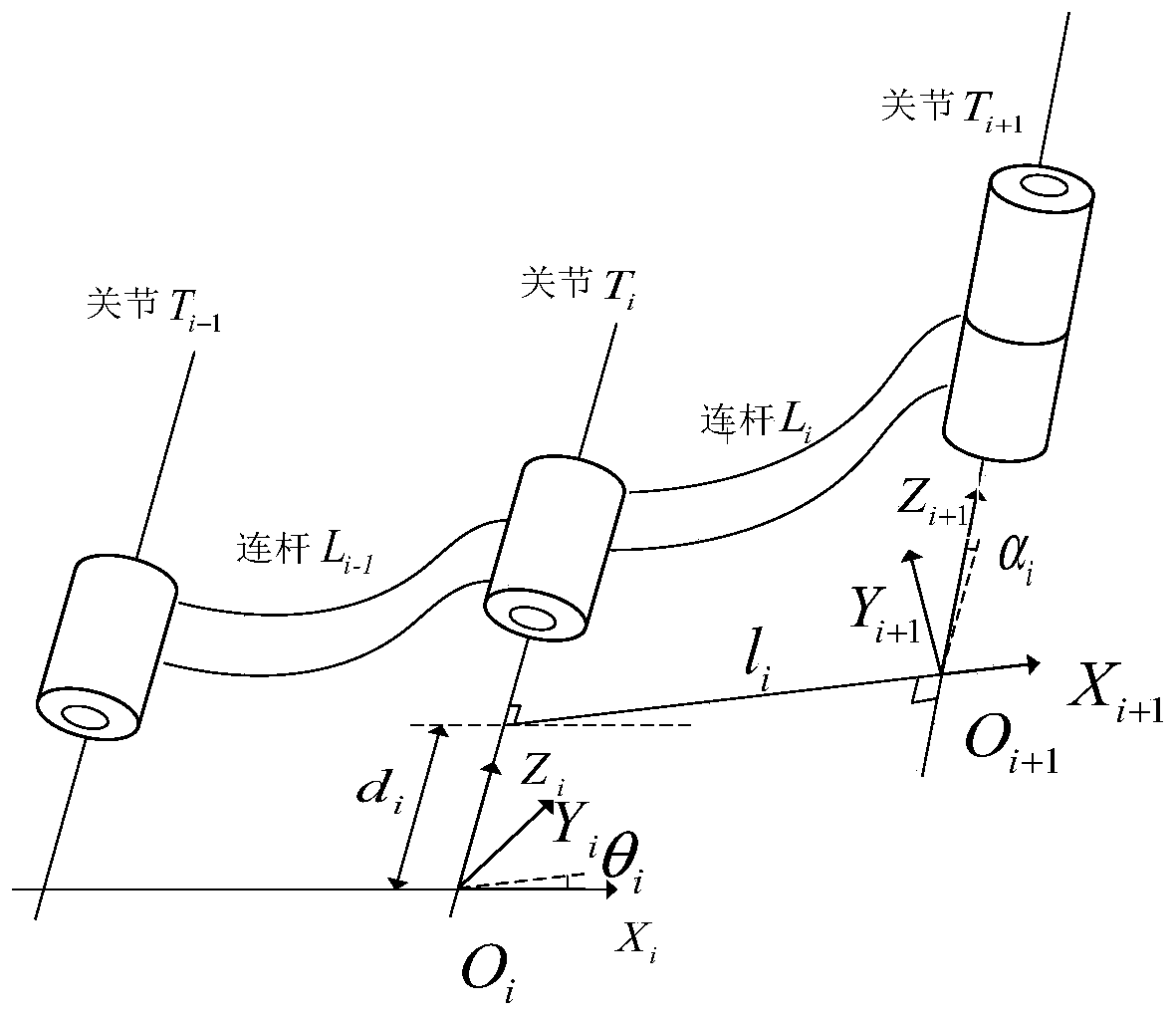

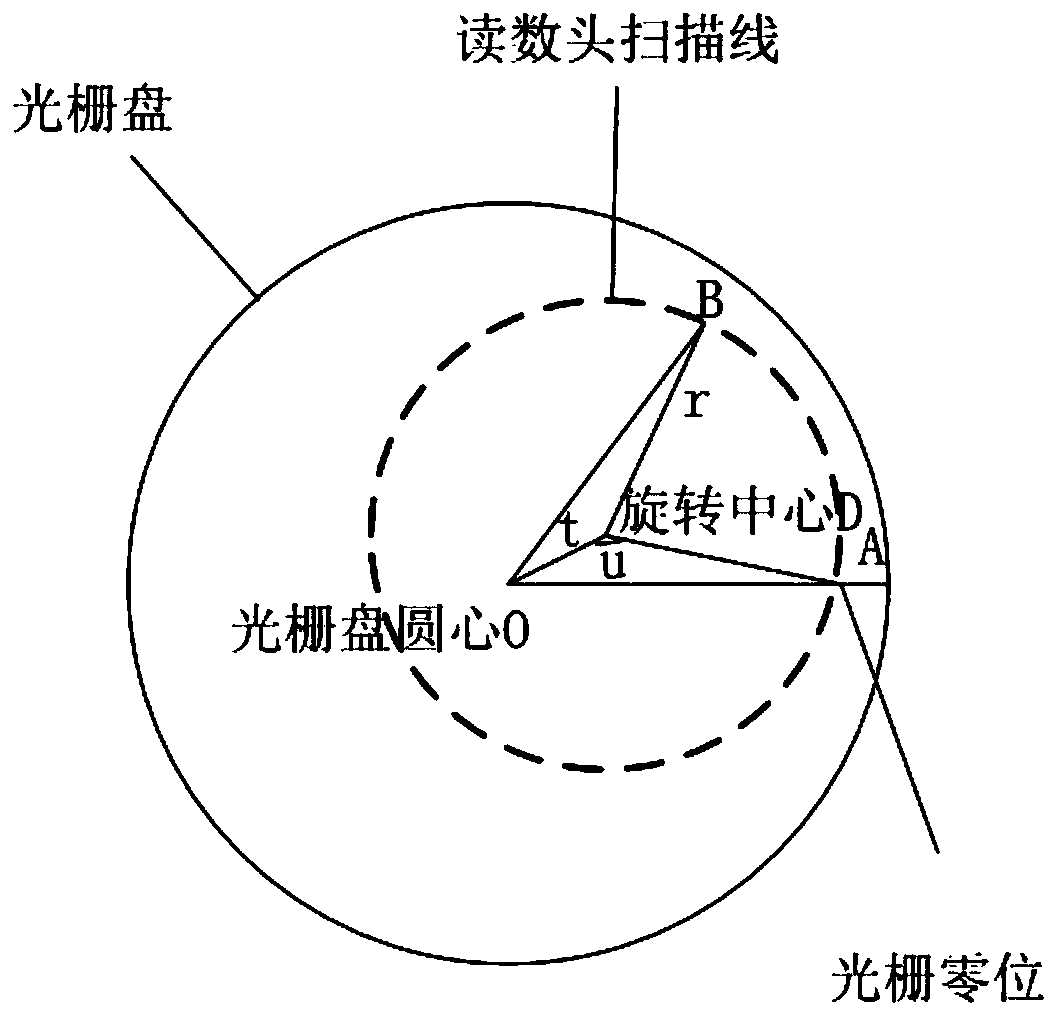

[0061] The structure of the flexible arm coordinate measuring machine for the research object targeted by the circular grating eccentric parameter calibration method of the flexible arm coordinate measuring machine of the present invention is as follows figure 1 As shown, the flexible arm coordinate measuring machine is composed of a base 1, a fixed arm 2, a measuring arm 3, a rotating joint 4 and a measuring head 5. The flexible arm coordinate measuring machine has 6 degrees of freedom, of which 6 degrees of freedom Corresponding to 6 rotary joints, each joint is equipped with a circular grating angle sensor. Since the sensor has eccentricity errors due to processing, assembly and other reasons during the manufacturing process, each circular grating sensor needs to be calibrated when used. Adopt method of the present invention, comprise the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com