A side suction range hood

A range hood, side suction technology, applied in the removal of oil fume, heating methods, household stoves/stoves, etc., can solve the problems of oil fume inversion in public flues, affecting user experience, and large spacing between workstations, etc., to prevent The effect of odor diffusion and oil fume inversion, elimination of jitter, and high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

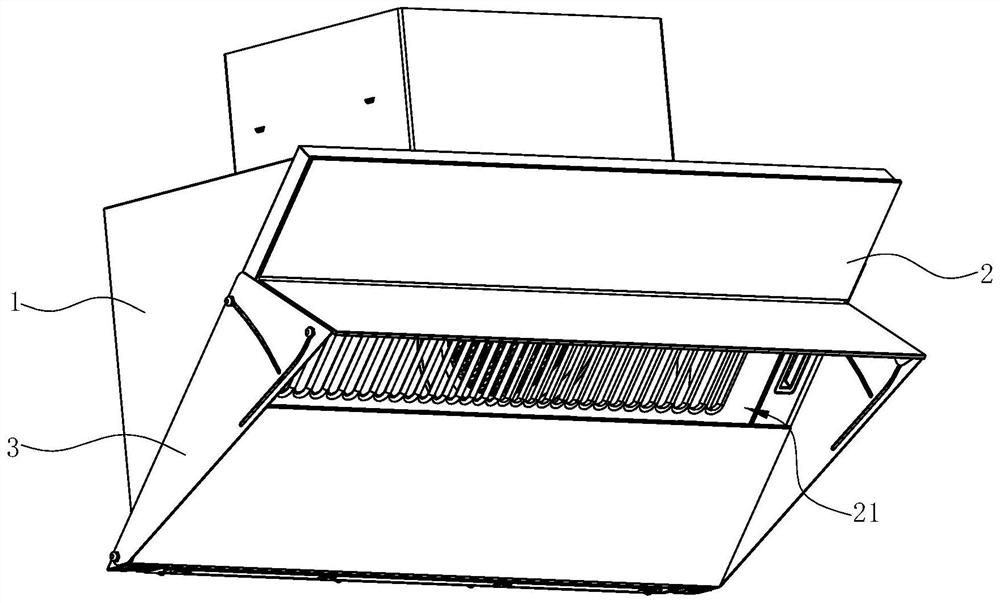

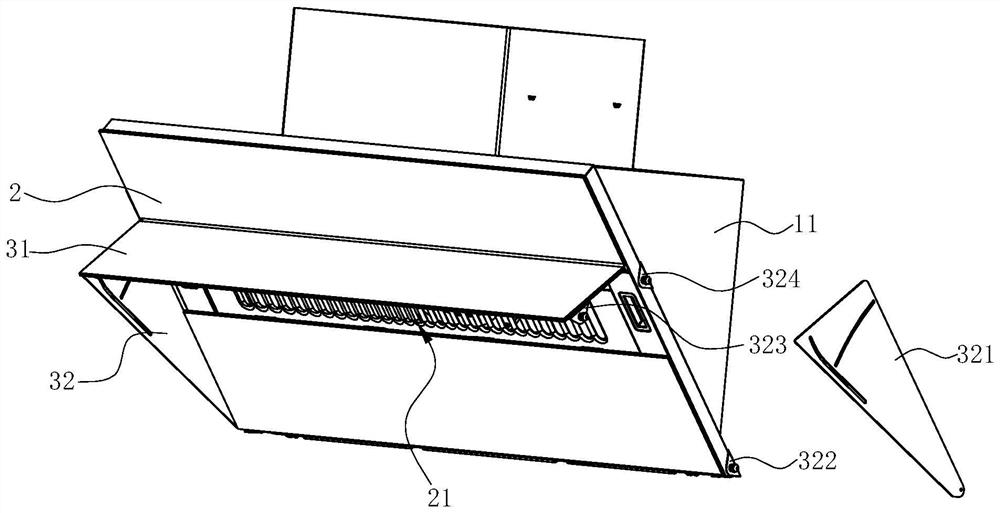

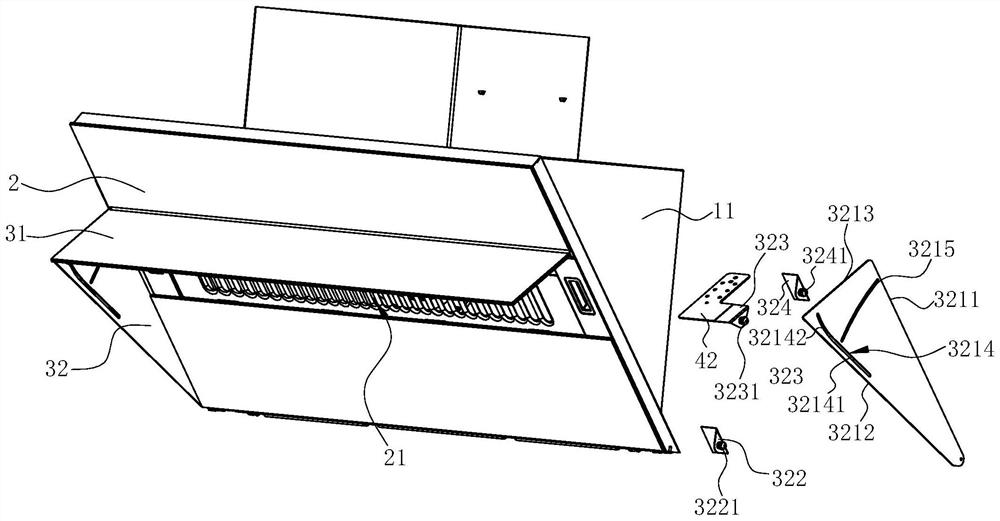

[0030] see Figure 1 ~ Figure 4 , a side suction range hood, comprising a housing 1, a panel 2 located on the front side of the housing 1, a smoke collection mechanism 3 and a drive transmission assembly 4, the smoke collection mechanism 3 includes a smoke baffle 31 and a fan mechanism 32. The front side of the housing 1 is gradually inclined backward from top to bottom, so that the panel 2 is also arranged gradually backward from top to bottom. The housing 1 includes side plates 11 located on the left and right sides. There is an air inlet 21 on the panel 2, the smoke baffle 31 is flat, and its upper end is hinged at the air inlet 21, so the lower end of the smoke baffle 31 is a free end, which can be rotated relative to the panel 2 to open or close the air inlet 21 .

[0031] There are two wing mechanisms 32 , which are respectively arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com