Construction method of novel side slope platform drainage ditch

A drainage ditch and platform technology, applied in waterway systems, water supply devices, sewer pipe systems, etc., can solve problems such as long construction period, high structural construction cost, and difficulty in using mechanical operations, and achieve low project cost, easy quality control, The effect of fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

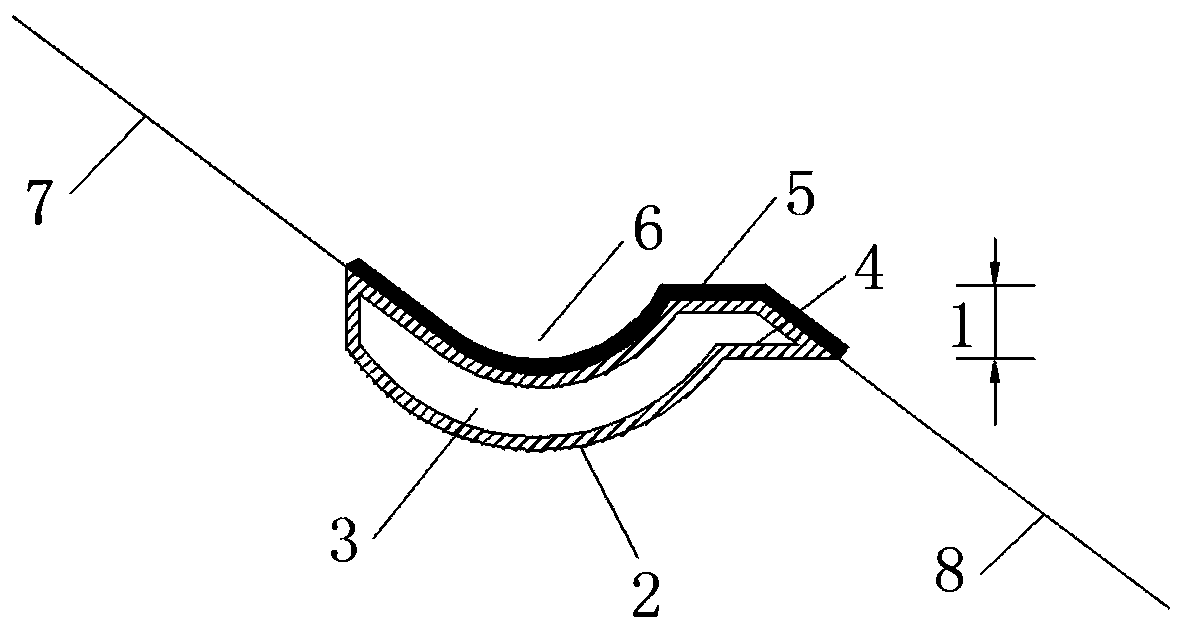

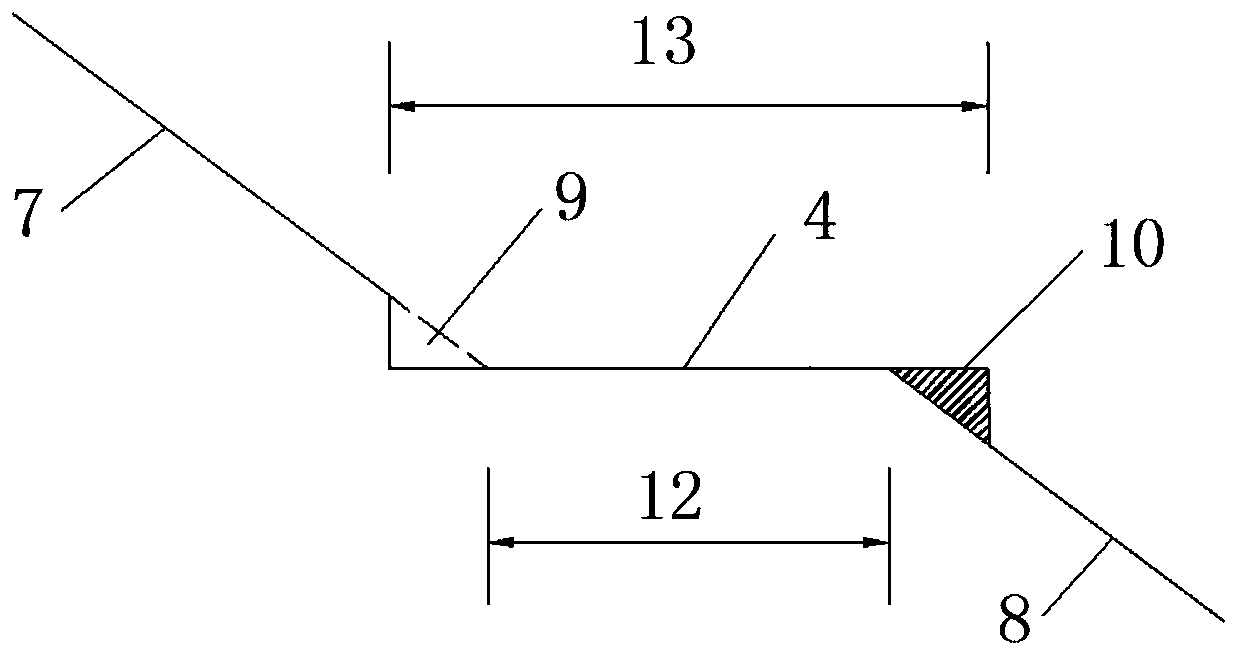

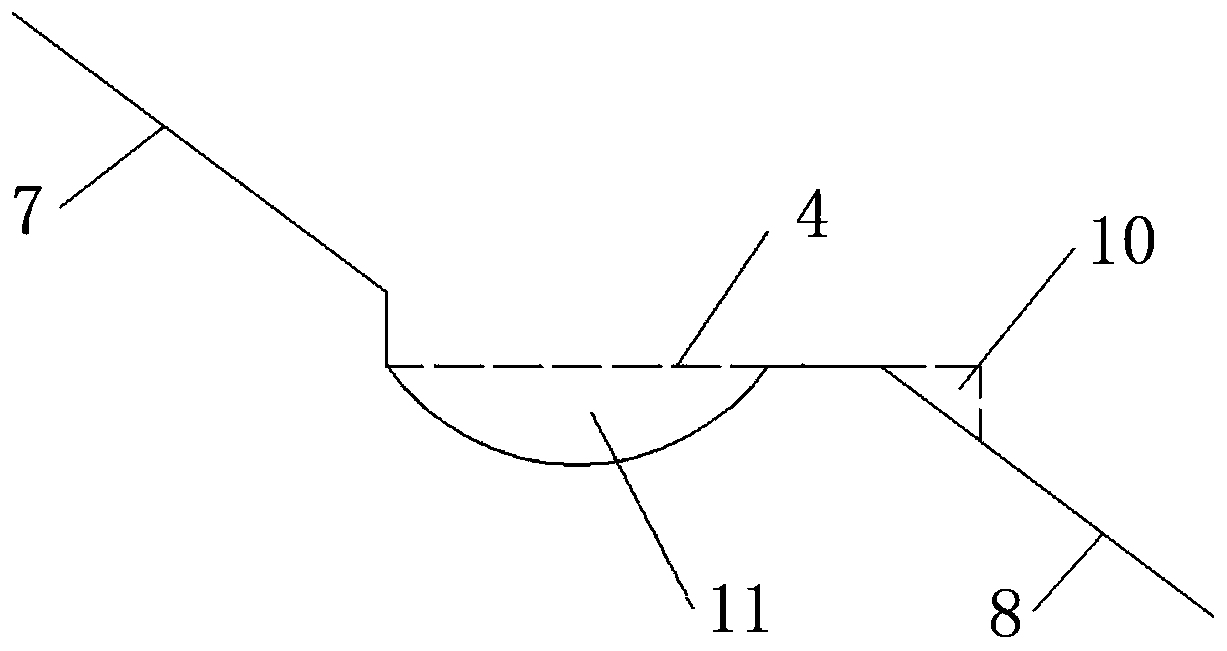

Embodiment Construction

[0016] The structure of a new type of slope platform drainage ditch proposed by the present invention is composed of a modified soil body, plus a glass fiber geogrid layer outside the modified soil and a plastering mortar layer on the surface of the platform side ditch; The solid weight mixing ratio of the modified soil is 10% cement and 90% excavated granite residual soil material, and then the prepared modified soil material is added with an appropriate amount of water, and mixed on site with an excavator until it is soft and plastic. , the structural molding is realized by wrapping the geogrid; the construction method of the novel slope platform drainage ditch has the following steps:

[0017] ① After the excavation work of the slope construction section is completed, excavation is firstly used to excavate and fill from the edge of the platform, and through the platform with a width of 1m, the granite with a horizontal distance of 75cm at the foot of the slope on the upper l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com