A film peeling delivery system

A transmission system and membrane device technology, applied in the field of industrial automation machinery, can solve the problems of small application range, low reliability, and poor stability, and achieve the effects of wide application range, easy maintenance, and low processing and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

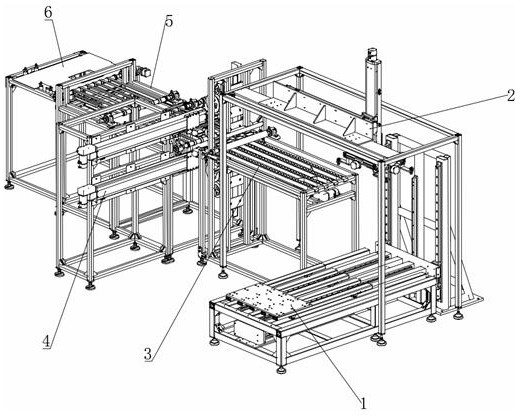

[0071] Embodiment 1: as Figure 1-32As shown, the film peeling transmission system includes a feeding device 1, a grabbing device 2, a film tearing device 3, a waste film recovery device 4, a conveying line 5, and a positioning device 6, and each device is fixed on the ground with anchor bolts. The film tearing device 3 is installed on one side of the feeding device 1, the grasping device 2 is arranged above the feeding device 1 and the film tearing device 3, the waste film recycling device 4 is installed on the side of the discharge end of the film tearing device 3, and the conveying line The inlet end of 5 is docked and installed on the discharge end of the film tearing device 3, forming a straight line film tearing platform with the film tearing device 3, and the positioning device 6 is arranged at the outlet end of the conveying line 5;

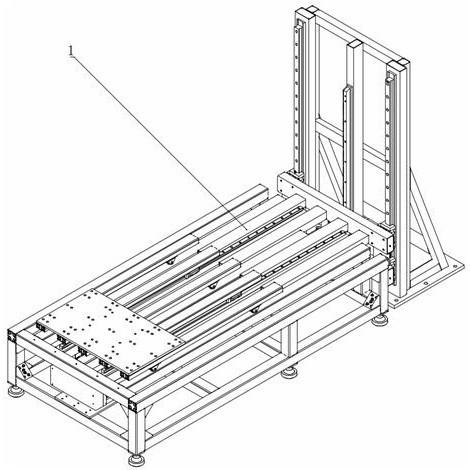

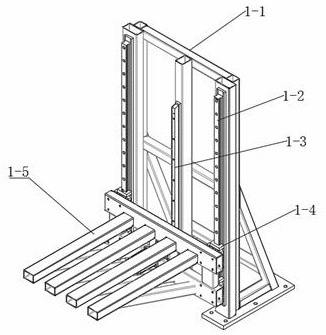

[0072] The feeding device 1 includes a base 1-1, a lifting guide rail 1-2, a helical rack 1-3, a lifting slider 1-4, a lifting frame 1-5...

Embodiment 2

[0080] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, the difference is that the waste film recovery device also includes a recovery box, and the recovery box 4-4 is arranged on one side of the support frame and below the linear module VI 4-3; the film tearing objects are different , the present embodiment takes the glass plate with the protective film as the object, adjusts the distance that the film tearing mechanism 3-4 moves up and down according to the size of the glass plate and the height of each lifting of the lifting frame 1-5; through the implementation of the equipment of this embodiment, it can be obtained The results are as follows: the glass plate can realize automatic feeding, film tearing, waste film recycling and positioning, the film tearing efficiency is high, stable and reliable, and the surface of the glass plate is not damaged.

Embodiment 3

[0081] Embodiment 3: The structure of this embodiment is the same as that of Embodiment 1. The difference lies in that the tearing film objects are different. In this embodiment, the light guide plate with a protective film is used as the object, and the tearing film mechanism 3-4 is adjusted to move up and down according to the glass plate size and material properties. The distance and the height of each lifting frame 1-5 can be obtained through the implementation of the equipment in this embodiment. The following results can be obtained: the light guide plate can realize automatic feeding, film tearing, recycling and positioning of waste film, and the film tearing efficiency is high, stable and reliable. The surface of the light guide plate is not damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com