Transformer shell paint spraying device

A technology of transformer housing and spray gun, which is applied in the direction of spraying devices and spray booths, etc., which can solve the problems of threatening the life safety of technicians, easy inhalation of paint by technicians, and high labor costs, so as to protect life safety, protect toxic particles, and have good painting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

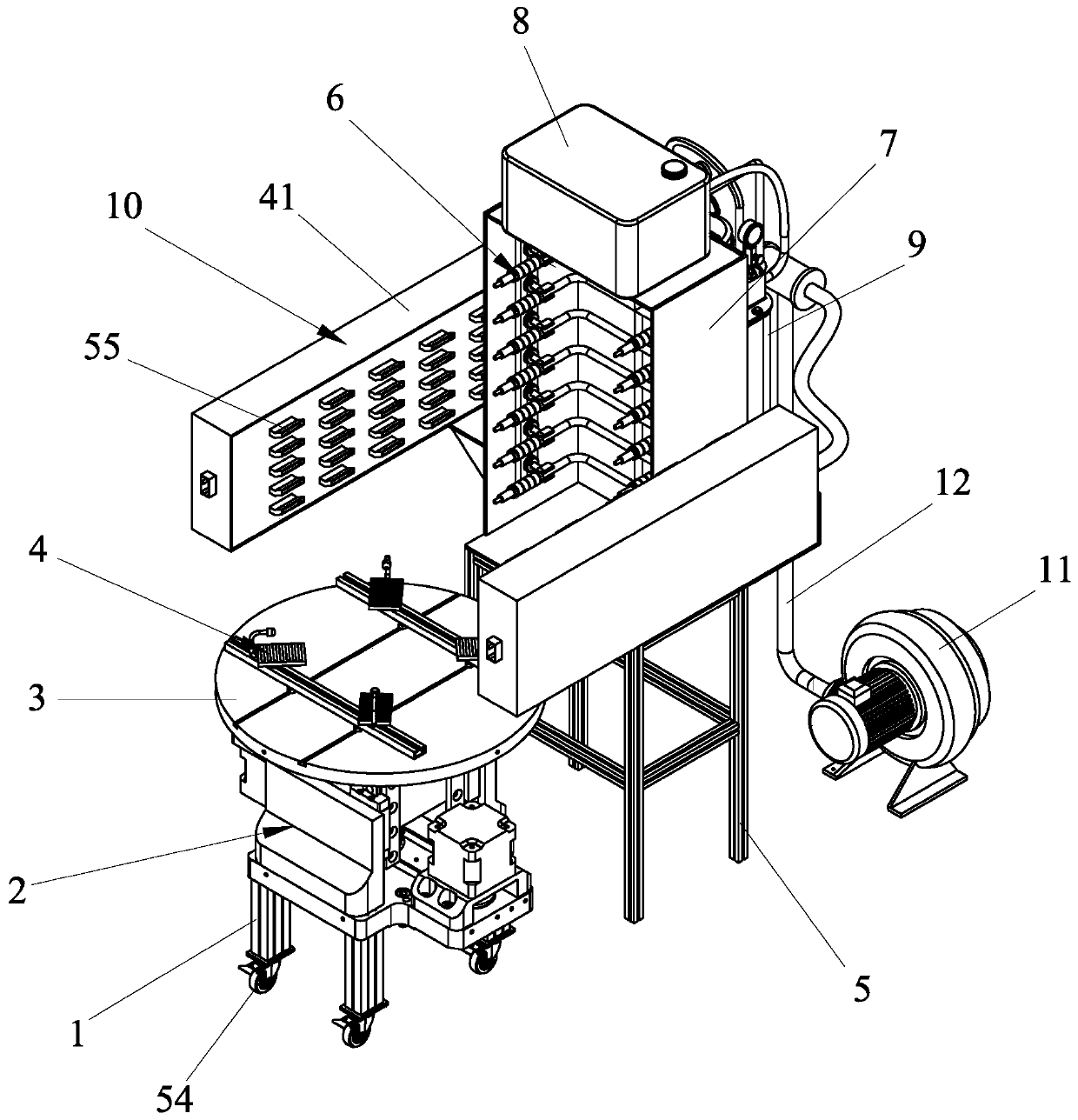

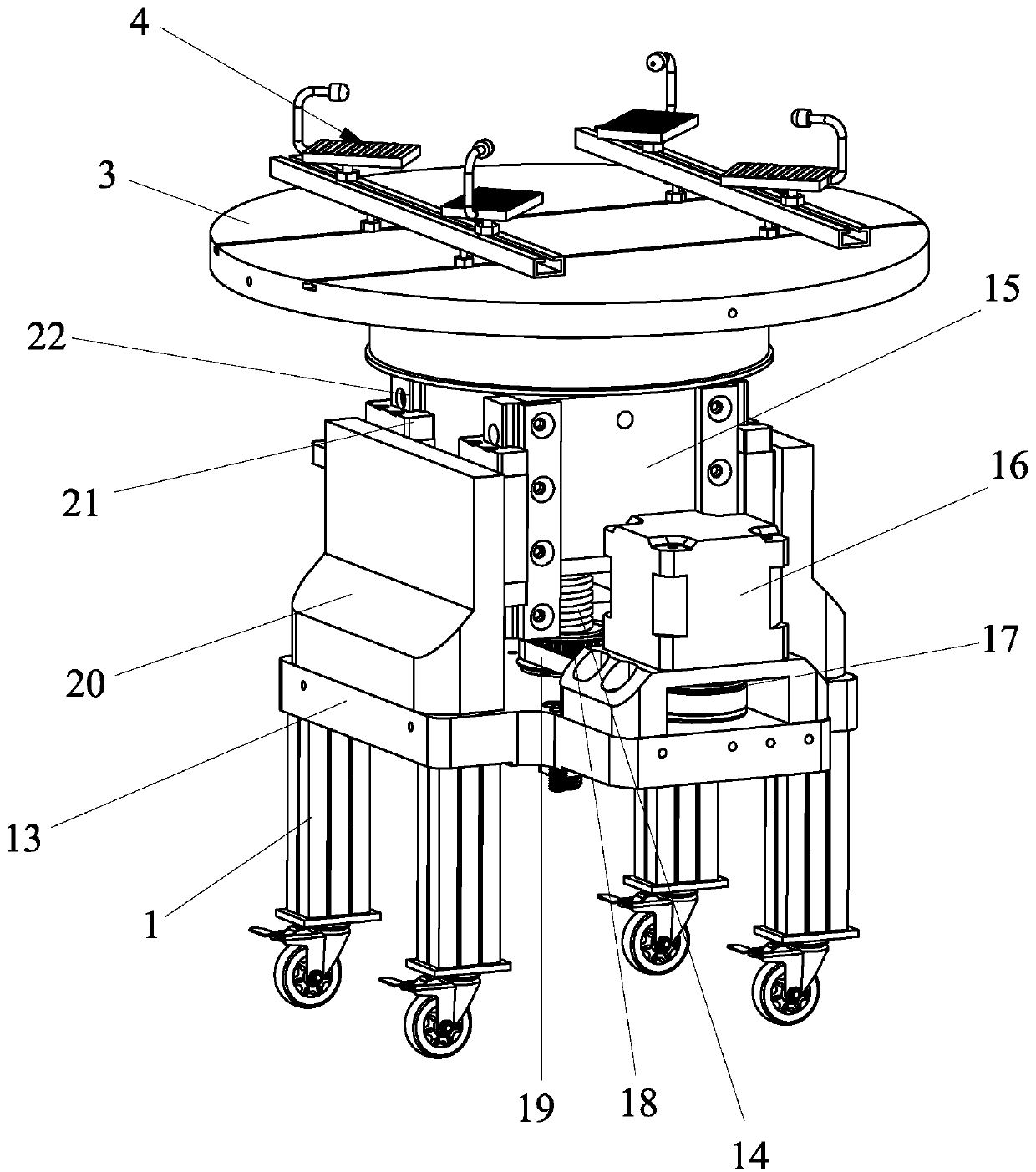

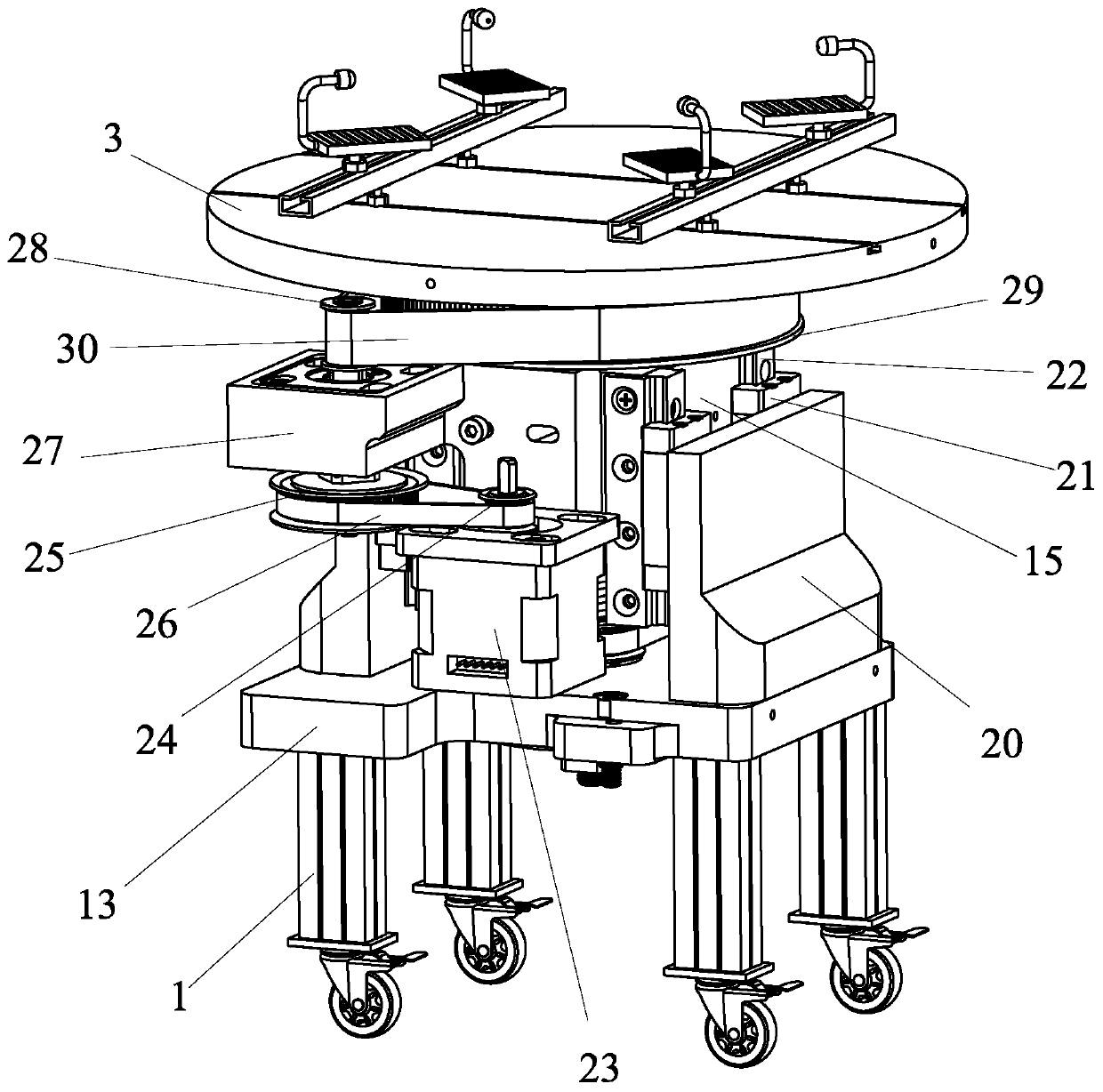

[0035] Embodiment: a kind of spraying device that is used for transformer shell, constitutes as Figure 1-9As shown, it includes a frame 1, an elevating and rotating mechanism 2 arranged on the frame 1, a workbench 3 arranged on the elevating and rotating mechanism 2, a clamping mechanism 4 arranged on the workbench 3, a The fixed frame 5 on the side and the painting mechanism 6 arranged on the fixed frame 5; the lifting and rotating mechanism 2 drives the workbench 3 to lift and rotate, and the clamping mechanism 4 on the workbench 3 is used to fix the transformer housing. The painting mechanism 6 is used for the painting of the transformer shell; the painting mechanism 6 includes an installation cabinet 7 arranged on the fixed frame 5, and a paint box 8 for storing paint is arranged above the installation cabinet 7, and the top of the paint box 8 For the paint inlet, the paint inlet is screwed tightly with a sealing cover, the rear side of the installation cabinet 7 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com