An integrated sorting and recycling device for construction waste

A construction waste, recycling device technology, applied in the direction of solid separation, magnetic separation, chemical instruments and methods, etc., can solve the problem of large consumption of land requisition costs, construction costs for garbage removal costs, and the destruction and sorting of recycled materials. Insufficient and other problems to achieve the effect of solving the poor sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

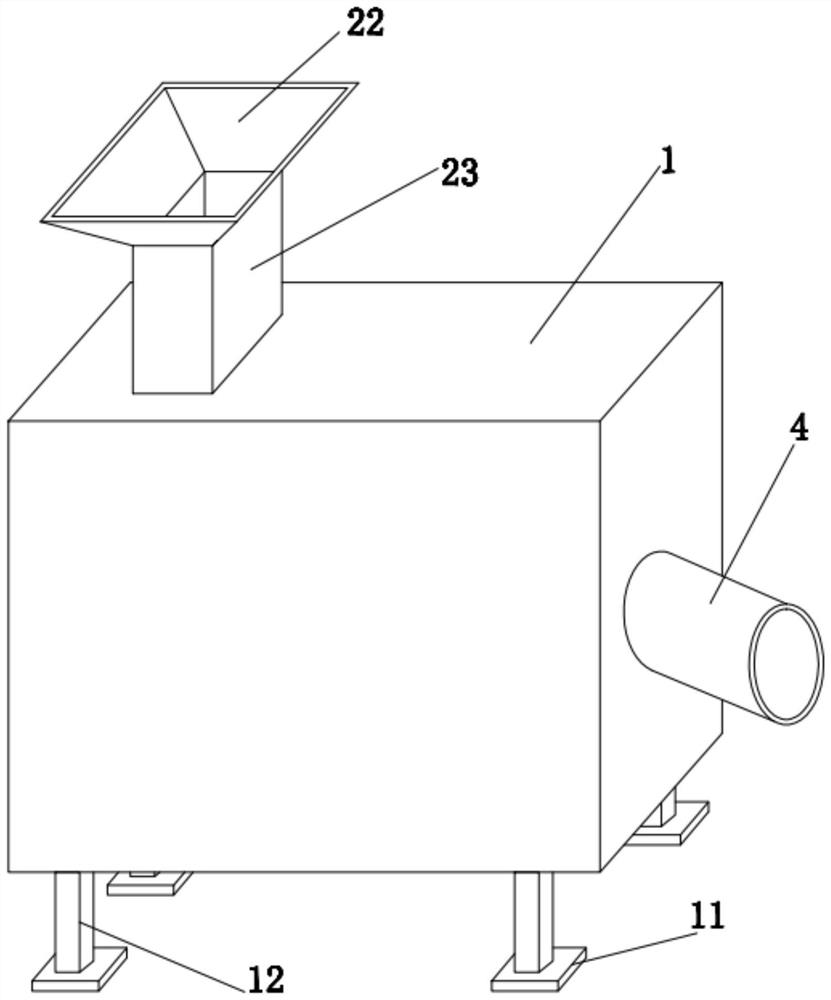

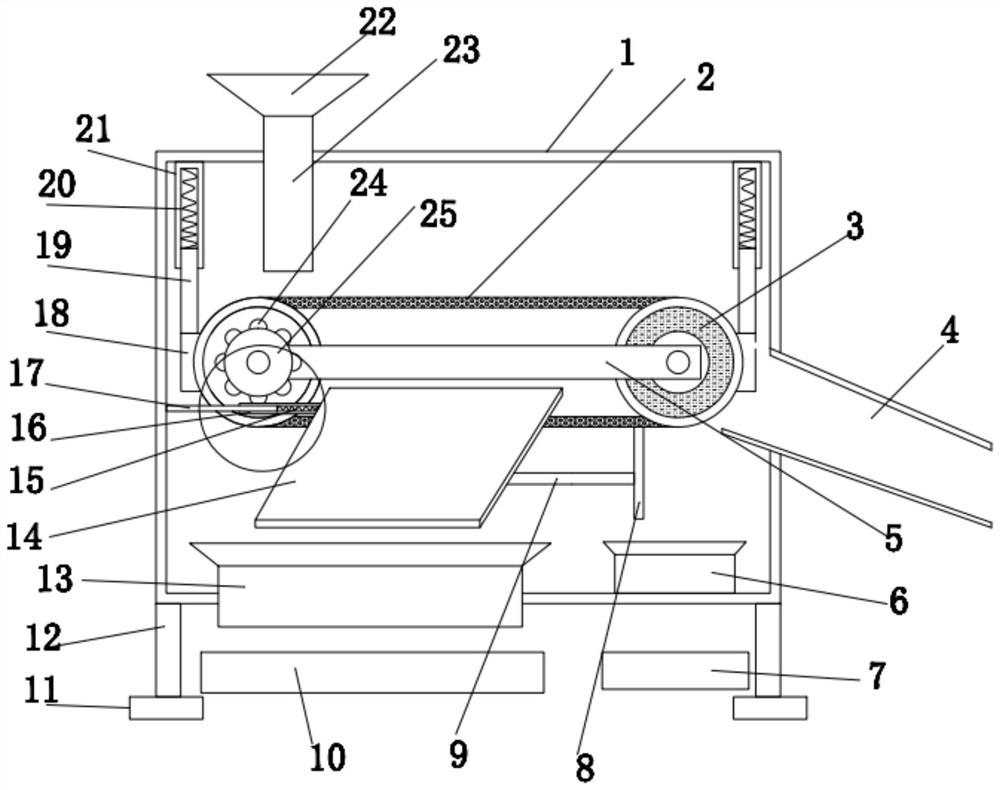

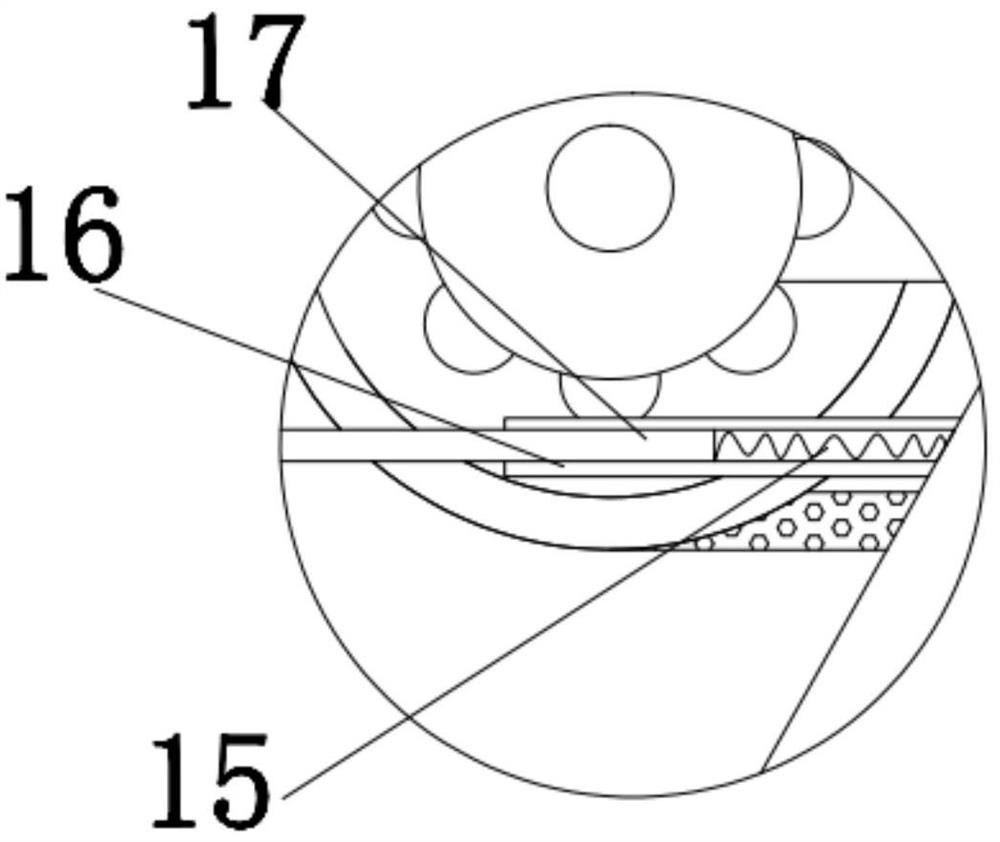

[0028] see Figure 1-3 , in an embodiment of the present invention, an integrated sorting and recycling device for construction waste, including a box body 1 and legs 12 arranged at the four corners of the lower end of the box body 1, the lower end of the legs 12 is provided with a A support block 11 with a large supporting area, a hopper 22 for feeding is provided above the box 1, and the lower port of the hopper 22 communicates with the feed port of the box 1 through a feeding pipe 23, and the box 1 There is a sorting mechanism for sorting waste inside. The sorting mechanism includes a suspension frame 18 suspended inside the box body 1 through a buffer component. The suspension frame 18 is provided with a conveyor belt 2 for conveying materials. , the box body 1 where the right end of the conveyor belt 2 is located is provided with a discharge pipe 4 for discharging the sorted materials, and the conveyor rollers at the left and right ends of the conveyor belt 2 are arranged...

Embodiment 2

[0036] The difference from Embodiment 1 is that in order to reduce the noise pollution generated during the operation of the device, the inner wall of the box body 1 is provided with a sound insulation layer.

Embodiment 3

[0038] In order to reduce the dust pollution generated when the device works, an exhaust channel is provided on the top of the box body 1, and the exhaust channel is connected to a negative pressure pump, and the exhaust end of the negative pressure pump is provided with a dust bag, so that the The dust generated inside the box body 1 is sucked away in time, and then filtered through the dust bag to reduce the dust pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com