Wire end peeling device for electrical experiment

An experimental, electric wire technology, which is applied to the installation of cable installation devices, electrical components, cables, etc., can solve the problems of easily hurting the teacher and inconvenient operation of the teacher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

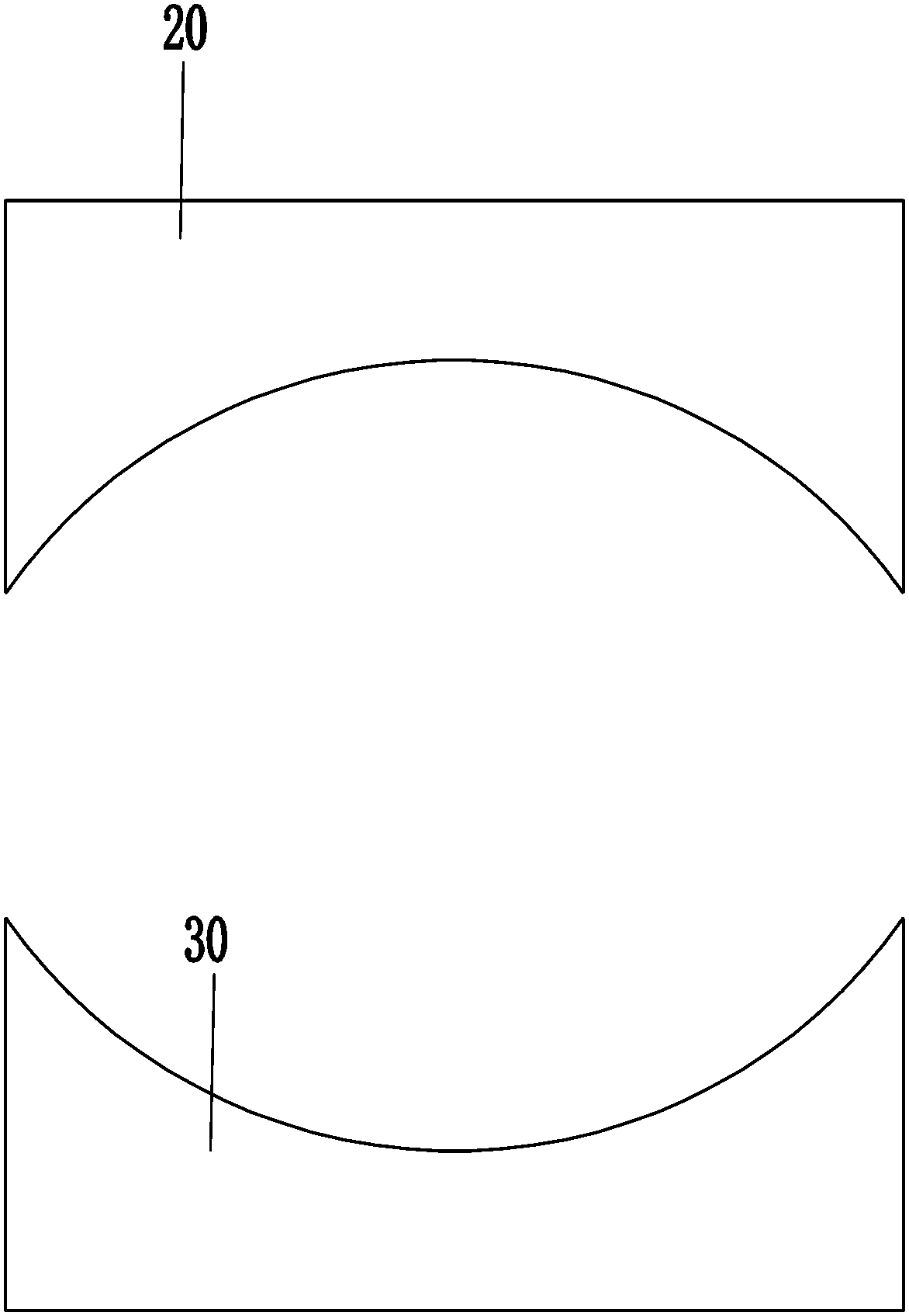

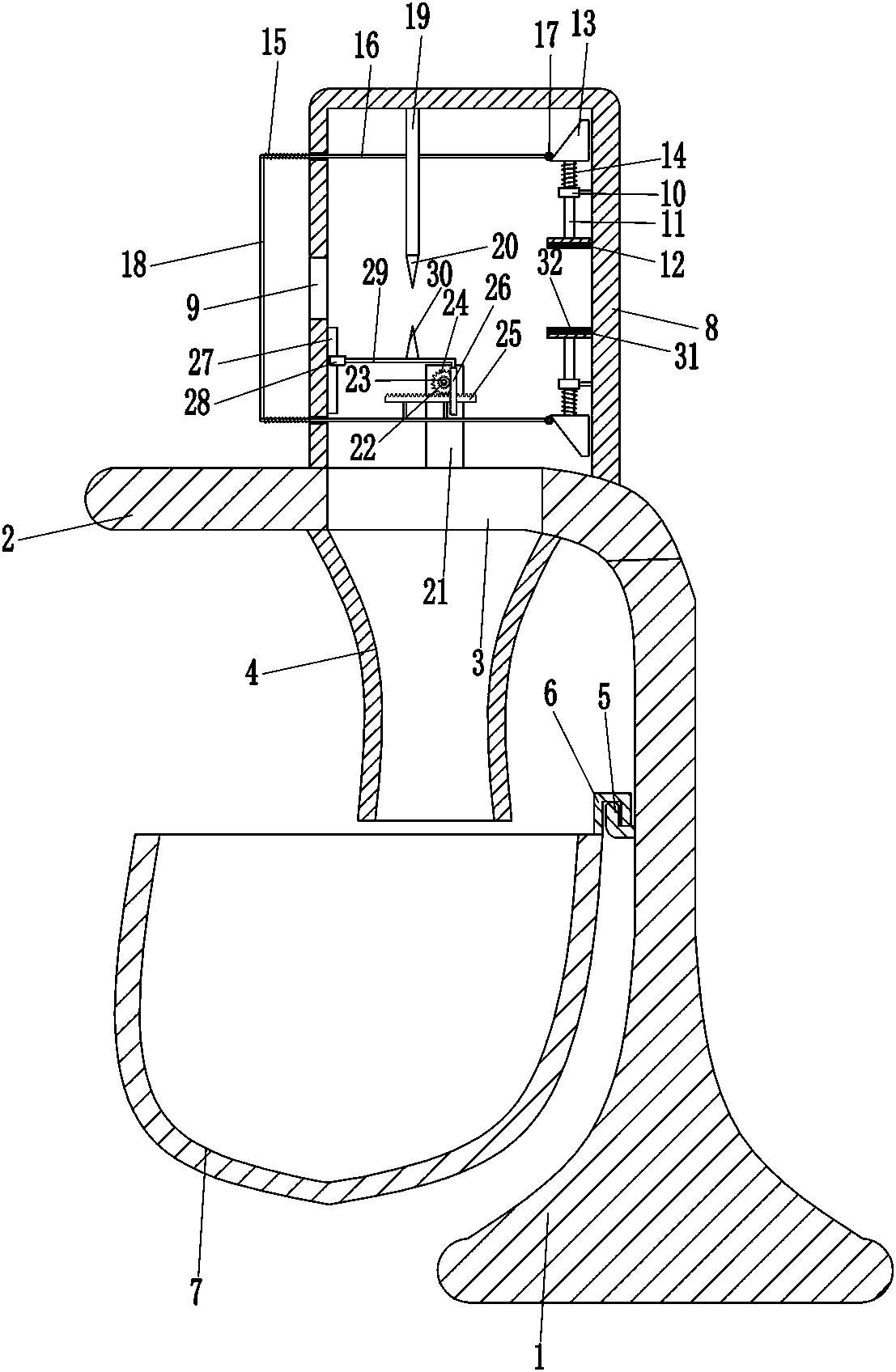

[0016] A kind of electric wire end peeling device for electrical experiments, such as Figure 1-2 As shown, it includes a support 1, a horizontal plate 2, a lower hopper 4, a mounting frame 8, a horizontal spring 15, a horizontal guide rod 16, a connecting rod 18, a vertical rod 19, an upper blade 20, a mounting plate 21, a rotating shaft 22, a small Gear 23, bull gear 24, horizontal tooth bar 25, vertical tooth bar 26, slide rail 27, slide block 28, cross bar 29 and lower blade 30, bearing 1 top is connected with horizontal plate 2, and horizontal plate 2 right parts open There is a through hole 3, the lower hopper 4 is connected to the right side of the bottom of the horizontal plate 2, the lower hopper 4 is located directly below the through hole 3, the mounting frame 8 is connected to the right side of the top of the horizontal plate 2, and a circular guide is opened in the middle part of the left side of the mounting frame 8. Hole 9, mounting frame 8 left side is provided...

Embodiment 2

[0018] A kind of electric wire end peeling device for electrical experiments, such as Figure 1-2 As shown, it includes a support 1, a horizontal plate 2, a lower hopper 4, a mounting frame 8, a horizontal spring 15, a horizontal guide rod 16, a connecting rod 18, a vertical rod 19, an upper blade 20, a mounting plate 21, a rotating shaft 22, a small Gear 23, bull gear 24, horizontal tooth bar 25, vertical tooth bar 26, slide rail 27, slide block 28, cross bar 29 and lower blade 30, bearing 1 top is connected with horizontal plate 2, and horizontal plate 2 right parts open There is a through hole 3, the lower hopper 4 is connected to the right side of the bottom of the horizontal plate 2, the lower hopper 4 is located directly below the through hole 3, the mounting frame 8 is connected to the right side of the top of the horizontal plate 2, and a circular guide is opened in the middle part of the left side of the mounting frame 8. Hole 9, mounting frame 8 left side is provided...

Embodiment 3

[0021] A kind of electric wire end peeling device for electrical experiments, such as Figure 1-2As shown, it includes a support 1, a horizontal plate 2, a lower hopper 4, a mounting frame 8, a horizontal spring 15, a horizontal guide rod 16, a connecting rod 18, a vertical rod 19, an upper blade 20, a mounting plate 21, a rotating shaft 22, a small Gear 23, bull gear 24, horizontal tooth bar 25, vertical tooth bar 26, slide rail 27, slide block 28, cross bar 29 and lower blade 30, bearing 1 top is connected with horizontal plate 2, and horizontal plate 2 right parts open There is a through hole 3, the lower hopper 4 is connected to the right side of the bottom of the horizontal plate 2, the lower hopper 4 is located directly below the through hole 3, the mounting frame 8 is connected to the right side of the top of the horizontal plate 2, and a circular guide is opened in the middle part of the left side of the mounting frame 8. Hole 9, mounting frame 8 left side is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com