Heating method of boiler for exploitation of offshore shale gas

A technology of shale gas mining and heating method, which is applied in the direction of combustion method, lighting and heating equipment, combustion product treatment, etc., can solve the problems of insufficient exhaust gas extraction capacity, etc., to avoid clogging, improve friction, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

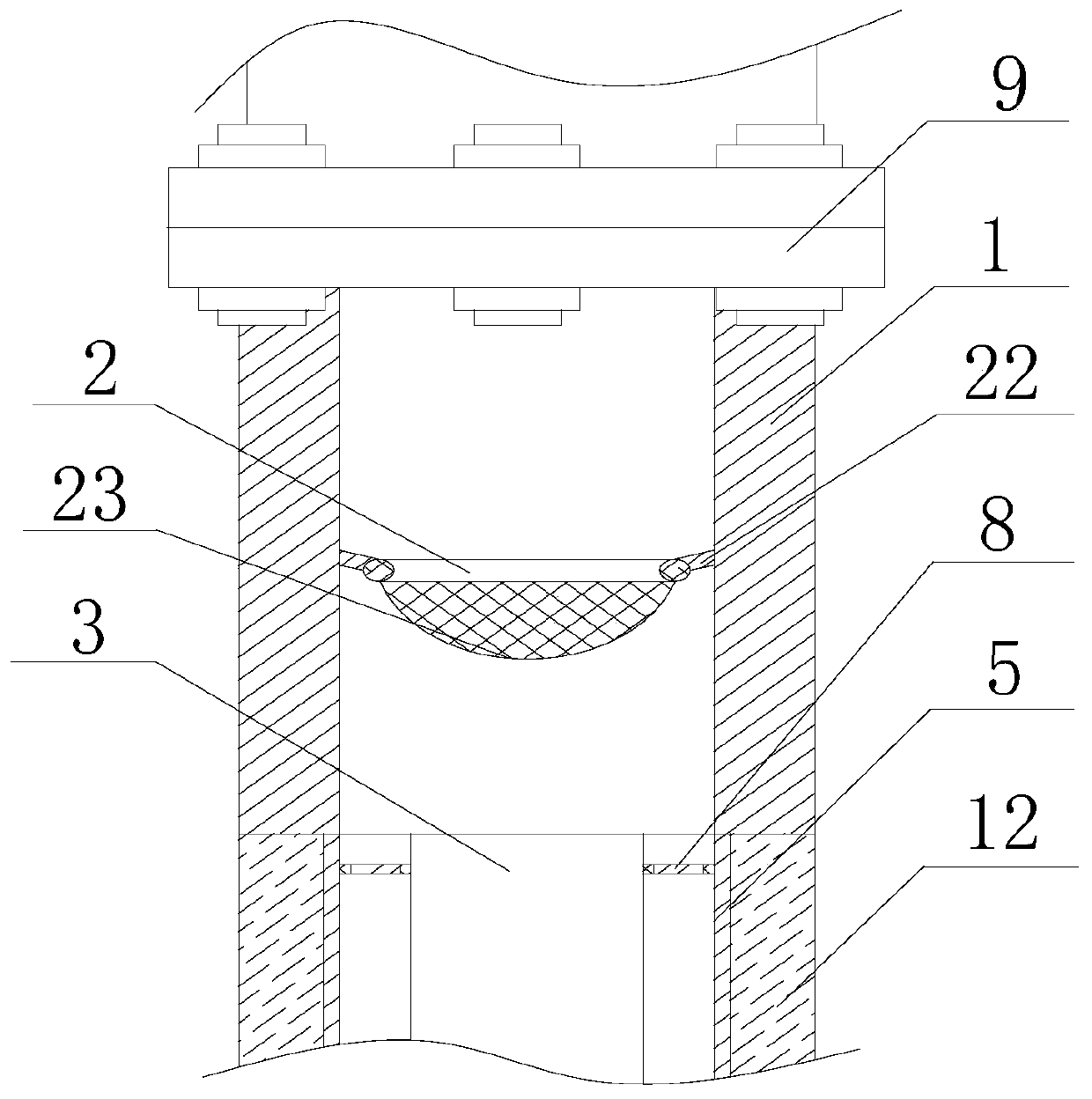

[0041] like figure 1 , figure 2 As shown, the seawater shale gas development adopts the heating method of the boiler, which includes the following steps:

[0042] 1) Add coal to the boiler, the exhaust gas from coal combustion is exported from the exhaust pipe 5 at the top, and then discharged through the exhaust pipe 1. The amount of coal added is 2 / 3 of the boiler volume. The flow control is 350-450m 3 / h;

[0043] 2) A coal addition port is provided on the boiler, and coal is added to the boiler in time;

[0044] 3), regularly clean the exhaust pipe: remove the dirt on the inner wall of the exhaust pipe 1 through the impurity removal device, the lower part of the exhaust pipe 1 is connected with the exhaust pipe 5 of the boiler, and the upper part of the exhaust pipe 1 is provided with Fan, the upper part of the exhaust pipe 1 is connected with the air outlet pipe through the flange plate 9;

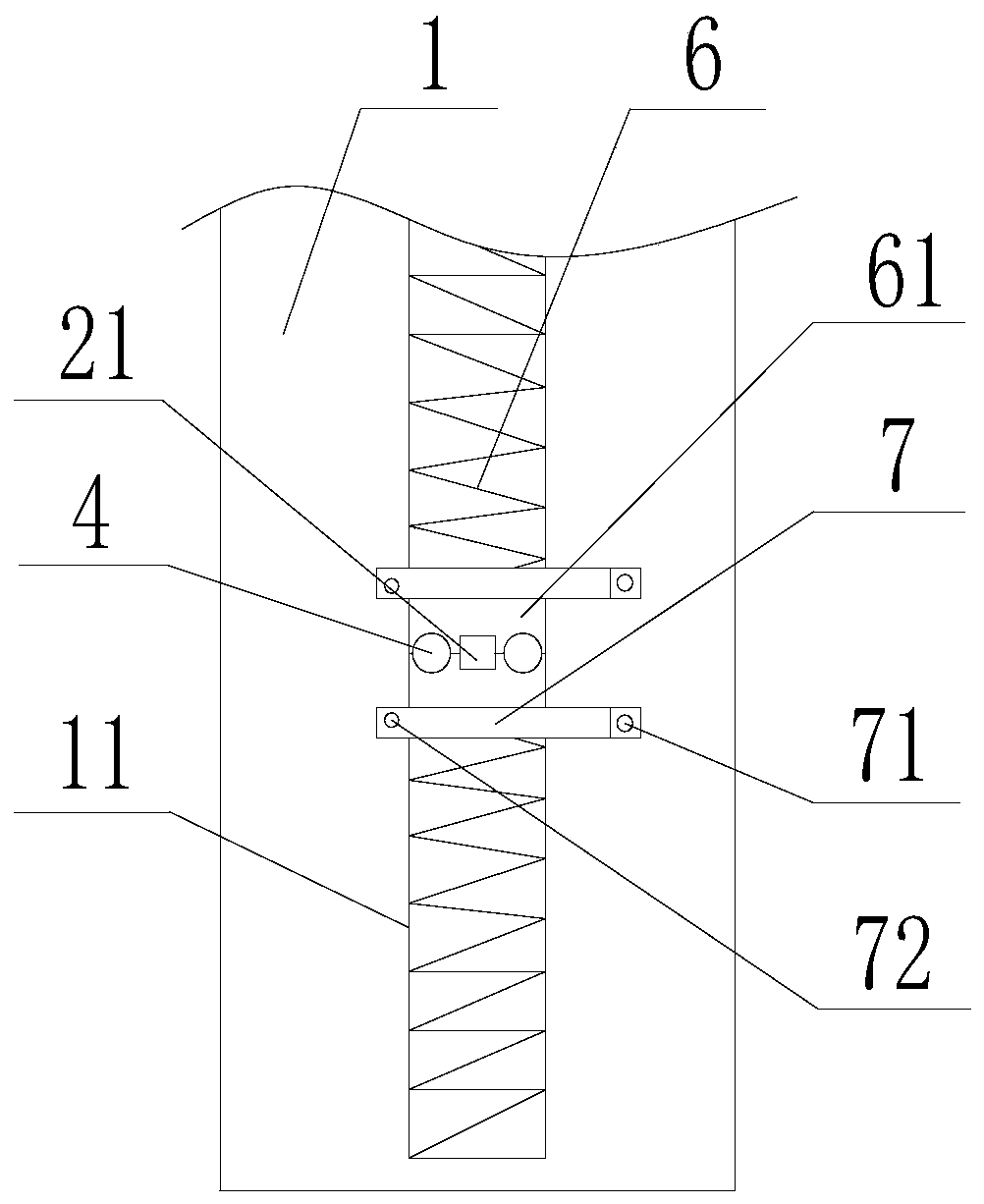

[0045] The impurity removal device includes an exhaust pipe 1, and the lowe...

Embodiment 2

[0047] like figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, the inner end of the sliding plate 61 is provided with a semi-circular arc groove, the inner wall of the semi-circular arc groove is a threaded surface, and also includes an auxiliary row threaded with the semi-circular arc groove. Duct 4.

Embodiment 3

[0049] like figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1 or Embodiment 2, the inner diameter of the annular scraper 22 gradually increases from one end connected to the annular card 2 to the other end, and the radius of the annular scraper 22 is the largest The end is in close contact with the inner wall of the exhaust pipe 1; the inner side of the exhaust pipe 5 is provided with an auxiliary exhaust pipe 3, and an annular filter screen 8 is arranged between the auxiliary exhaust pipe 3 and the exhaust pipe 5. The filter screen 8 is arranged directly below the annular scraper 22; the inner and outer ends of the annular filter screen 8 are provided with annular elastic sheets, and the annular filter screen 8 is clamped on the auxiliary by the elastic action of the annular elastic sheet. Between the exhaust pipe 3 and the exhaust pipe 5; the outer wall of the operating rod 21 is set as a threaded surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com