VOCs waste gas treatment device

A technology of exhaust gas treatment device and exhaust passage, which is applied in combustion methods, lighting and heating equipment, combustion types, etc., can solve the problems of many gas pipelines, energy loss, complicated control methods, etc., and achieves simple gas path and work. The effect of stable state and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention should not be construed as limiting the protection scope of the present invention.

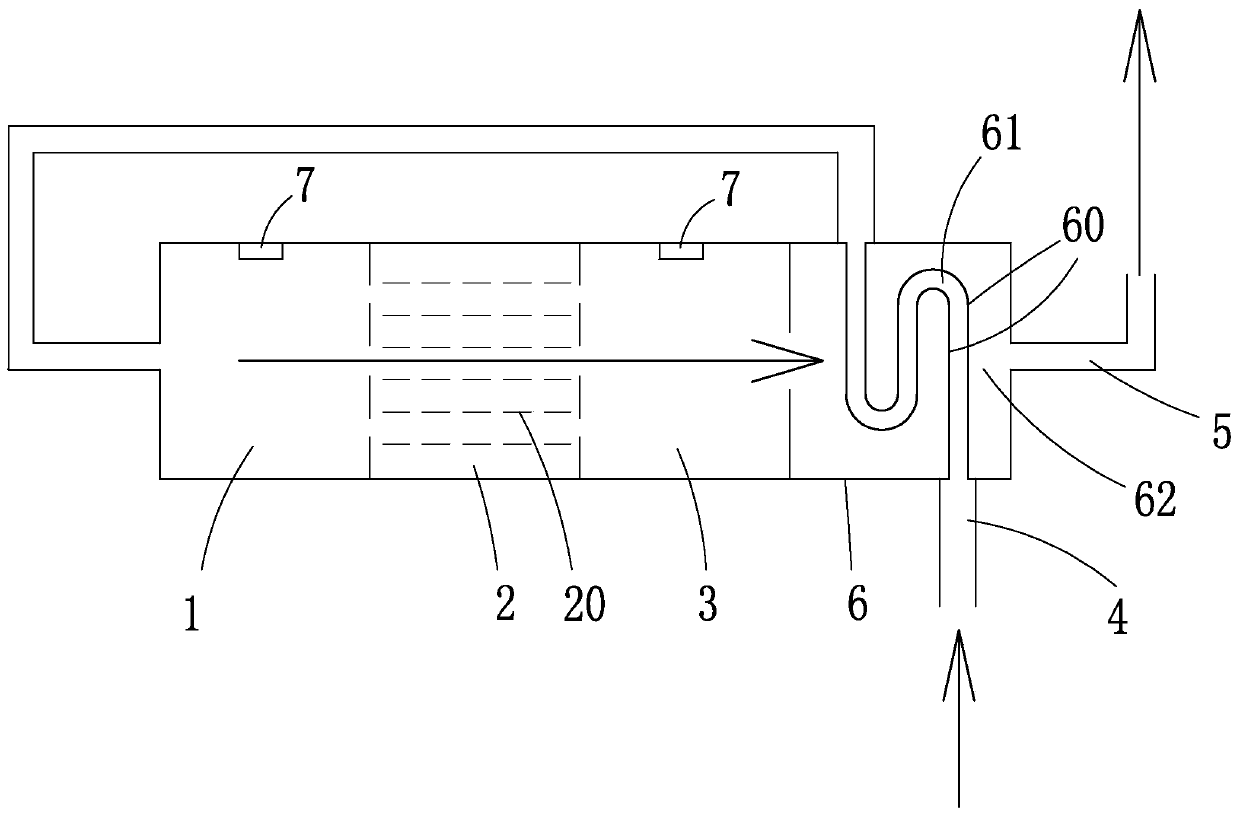

[0017] refer to figure 1 , VOCs exhaust gas treatment device, which includes a first combustion chamber 1, a regenerator 2, a second combustion chamber 3, an intake passage 4, an exhaust passage 5 and a heat exchanger 6; the first combustion chamber 1 and the second combustion chamber The combustion chamber 3 is provided with a burner 7, and the heat storage chamber 2 is provided with a heat storage structure 20; the first combustion chamber 1 and the second combustion chamber 3 communicate through the heat storage chamber 2; the heat exchanger 6 is a partition wall heat exchanger, which has a first channel 61, a second channel 62 and a parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com