Automatic material change device for bobbin case storage tray

A storage tray, automatic technology, applied in auxiliary devices, bobbin winding in sewing machines, mechanism of embroidery machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

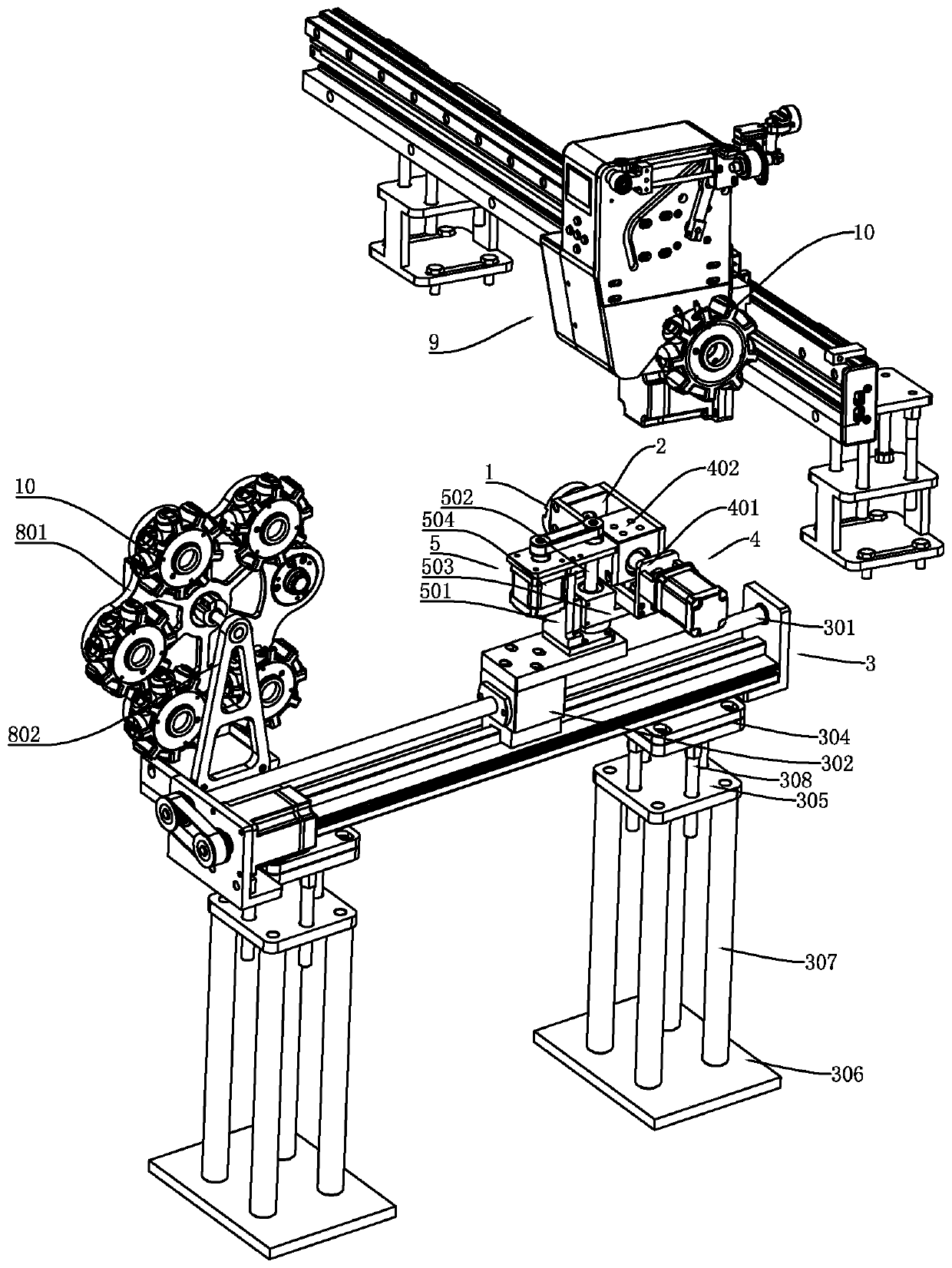

[0048] like figure 1 , figure 2 As shown, a bobbin case storage tray automatic refueling device of the present invention includes a retrieving head 1 , a floating mechanism 2 , an adjusting mechanical arm and a conveying mechanism 3 .

[0049] The adjusting mechanical arm includes a lateral movement adjustment arm 4 and a lifting height adjustment arm 5 of a lateral movement reclaiming mechanism. Under the action, the traversing direction of the traversing adjusting arm 4 is deflected, and the adjusting mechanical arm is slidably connected to the conveying mechanism 3 , and the adjusting mechanical arm and the conveying mechanism 3 are used to adjust the spatial position of the picking head 1 .

[0050] The conveying mechanism 3 includes a conveying screw guide rail 301 and a conveying sliding seat 302 , the conveying sliding seat 302 is slidably connected to the conveying screw guide rail 301 , and an adjusting mechanical arm is arranged on the conveying sliding seat 302 . ...

Embodiment 2

[0070] The specific structure of the floating mechanism 2 in this application can adopt alternative schemes. The biggest difference between this embodiment and the above-mentioned embodiment 1 is that the floating mechanism 2 with the following mechanism is adopted.

[0071] like Figure 5 , Image 6 As shown, the floating mechanism 2 includes a connecting frame and an elastic reset member, the connecting frame is connected to the traverse adjustment arm 4, and the picking head 1 is movably connected to the connecting frame so that the picking head 1 can move obliquely relative to the connecting frame, and the connecting frame A number of elastic return parts are arranged between the reclaimer 1 and the reclaimer 1. When the reclaimer 1 can be deflected relative to the lateral movement direction of the traversing adjustment arm 4 under the action of an external force, the elastic reset members exert elasticity on the reclaimer 1. Reset force.

[0072] The connecting frame in...

Embodiment 3

[0075] The specific structure of the floating mechanism 2 in this application can adopt alternative schemes. The biggest difference between this embodiment and the above-mentioned embodiment 1 is that the floating mechanism 2 with the following mechanism is adopted.

[0076] like Figure 7 , Figure 8 As shown, the floating mechanism 2 includes a connecting frame and an elastic reset member, the connecting frame is connected to the traverse adjustment arm 4, and the picking head 1 is movably connected to the connecting frame so that the picking head 1 can move obliquely relative to the connecting frame, and the connecting frame A number of elastic return parts are arranged between the reclaimer 1 and the reclaimer 1. When the reclaimer 1 can be deflected relative to the lateral movement direction of the traversing adjustment arm 4 under the action of an external force, the elastic reset members exert elasticity on the reclaimer 1. Reset force.

[0077] The connecting frame i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com