Cyclopentane low-pressure foaming machine

A foaming machine and cyclopentane technology are applied in the field of low-pressure cyclopentane foaming machines to achieve good mixing effect and improve pouring efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

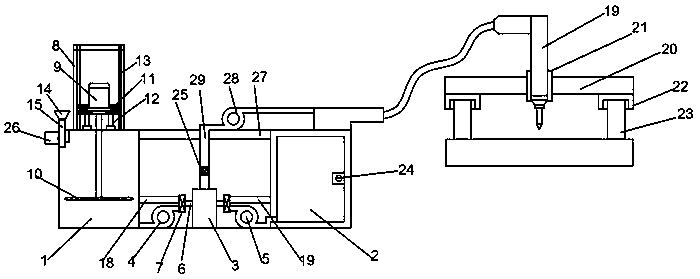

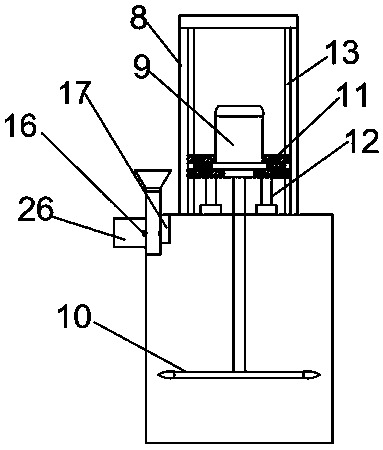

[0024] see figure 1 , a cyclopentane low-pressure foaming machine, comprising a common material mixing chamber 1, a hazardous material mixing isolation chamber and a pouring manipulator, a high-temperature heating mixing box 3 is arranged between the common material mixing chamber 1 and the dangerous material mixing chamber 2, A leak alarm 24 is installed in the hazardous material mixing isolation chamber. The common material mixing chamber 1 and the dangerous material mixing chamber 2 are connected to the high-temperature heating mixing chamber through the first plunger pump 4 and the second plunger pump 5 respectively. Both ends of the mixing box are connected to the first plunger pump 4 and the second plunger pump 5 through the connecting pipe 6 and the three-way solenoid v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com