Wire drawing equipment suitable for tool factories

A tool factory and wire drawing technology, which is applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of unfavorable production efficiency of factory personnel, unsightly tools, and stains, so as to reduce rust and contamination Probability of smudges, improved aesthetics, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

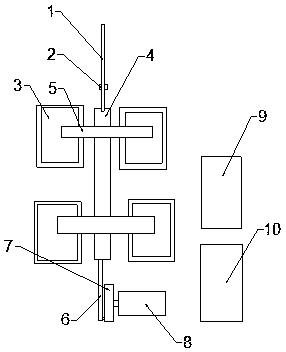

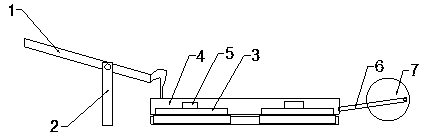

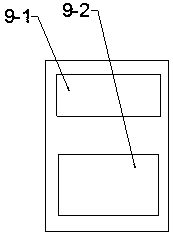

[0018] Such as Figure 1 to Figure 5 As shown, this is suitable for wire drawing equipment in tool factories, including lever 1, lever bracket 2, wire drawing plate 3, main beam of wire drawing machine 4, cross arm 5, push-pull rod 6, flywheel 7, reciprocating motor 8, power supply 9 and control box 10. The lever 1 is connected to the lever bracket 2 through a screw, one end of the lever 1 is connected to one end of the main beam 4 of the wire drawing machine through a screw, and several cross arms 5 are installed on the surface of the main beam 4 of the wire drawing machine, and the two ends of the cross arm 5 are respectively fixed and installed Wire drawing plate 3, one end of wire drawing machine main beam 4 is connected with push-pull rod 6 by screw, and push-pull rod 6 is connected reciprocating motor 8 through flywheel 7, and reciprocating motor 8 is connected c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com