A bottle cap double-sided marking machine

A marking machine and bottle cap technology, which is applied in auxiliary welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as occupying a large space, reducing marking efficiency, and bottle caps bumping and slipping out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

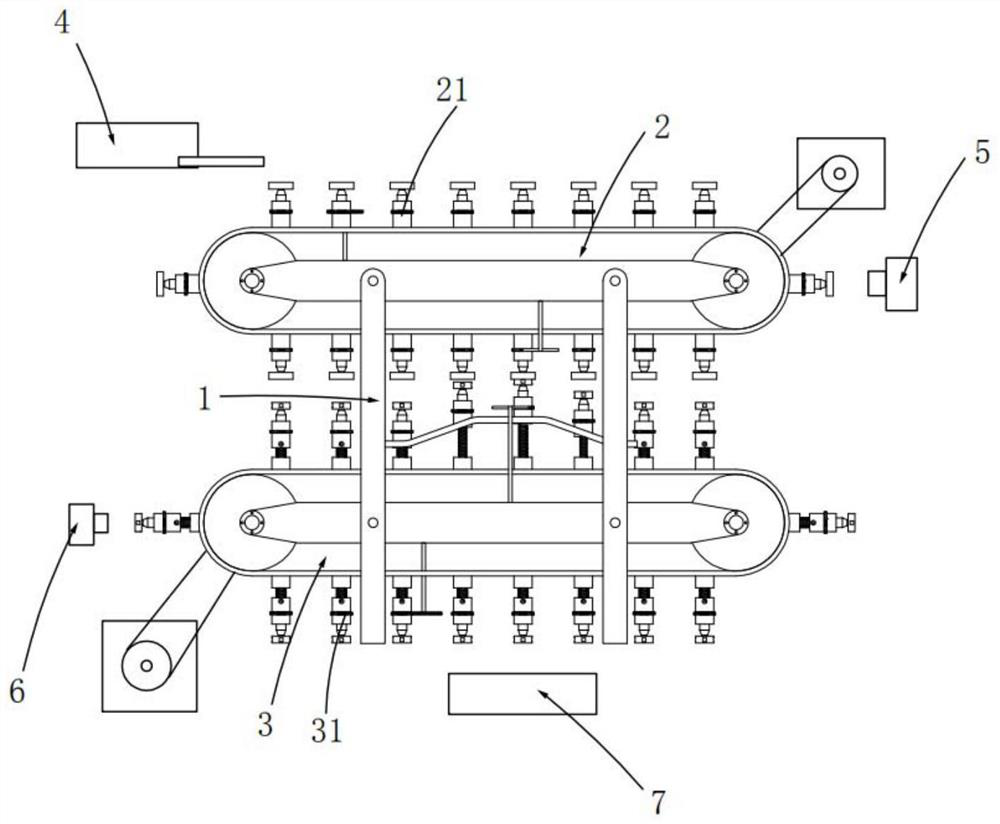

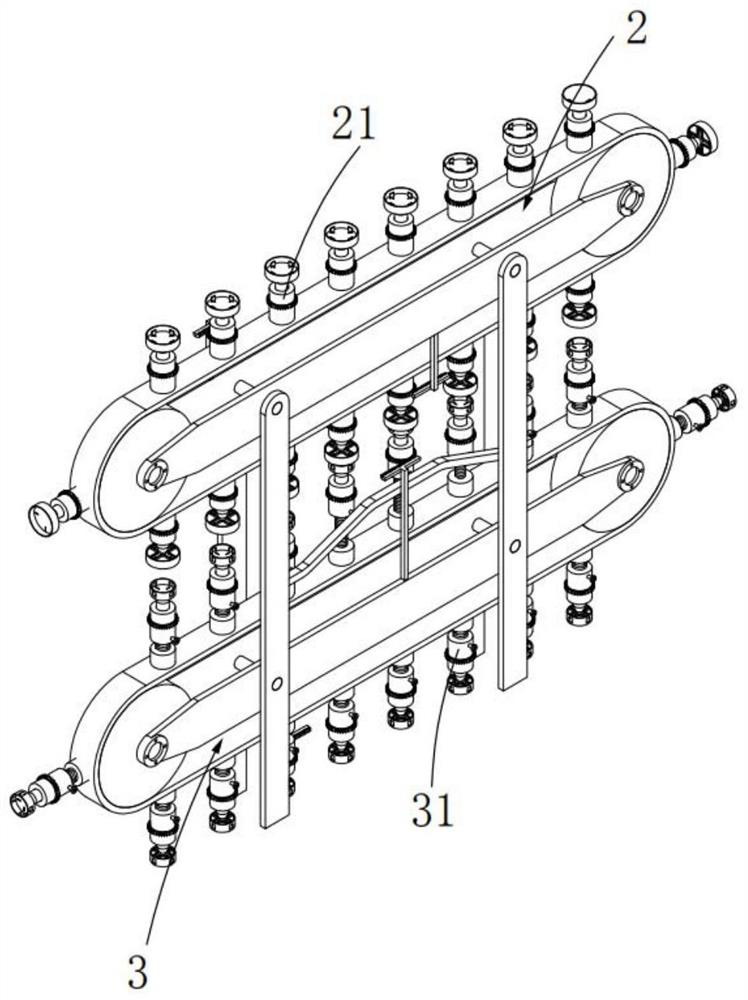

[0076] Such as figure 1 and 2 Shown, a kind of bottle cap double-sided marking machine, it comprises:

[0077] bracket 1;

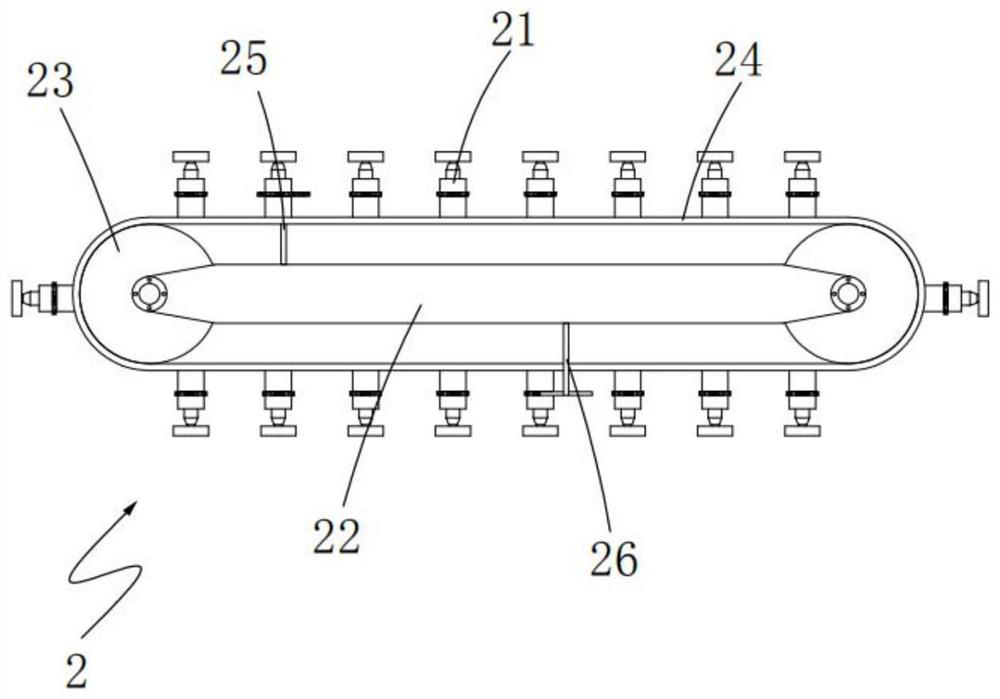

[0078] The first conveying mechanism 2, the first conveying mechanism 2 is arranged on the support 1, the first clamping seat 21 is evenly arranged on the first conveying mechanism 2 along its conveying direction, and the first clamping seat 21 21 clamping the outer peripheral surface of the bottle cap;

[0079] The second conveying mechanism 3, the second conveying mechanism 3 is arranged on the support 1, and it is located below the first conveying mechanism 2, and the second conveying mechanism 3 is evenly provided with second clamping along its conveying direction. Seat 31, the second clamping seat 31 clamps the inner circumferential surface of the bottle cap, and the conveying direction of the second conveying mechanism 3 is opposite to the conveying direction of the first conveying mechanism 2;

[0080] A cover sorting machine 4, the cover sorti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com