Double-wire sheath stripping servo crimping machine

A crimping machine and cable technology, applied in the direction of connection, connection by deformation, line/collector parts, etc., can solve the problems of unguaranteed efficiency and reliability, high resource occupation, and low crimping efficiency, etc. problems, to achieve the effect of simplifying mechanical complexity, saving resources and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

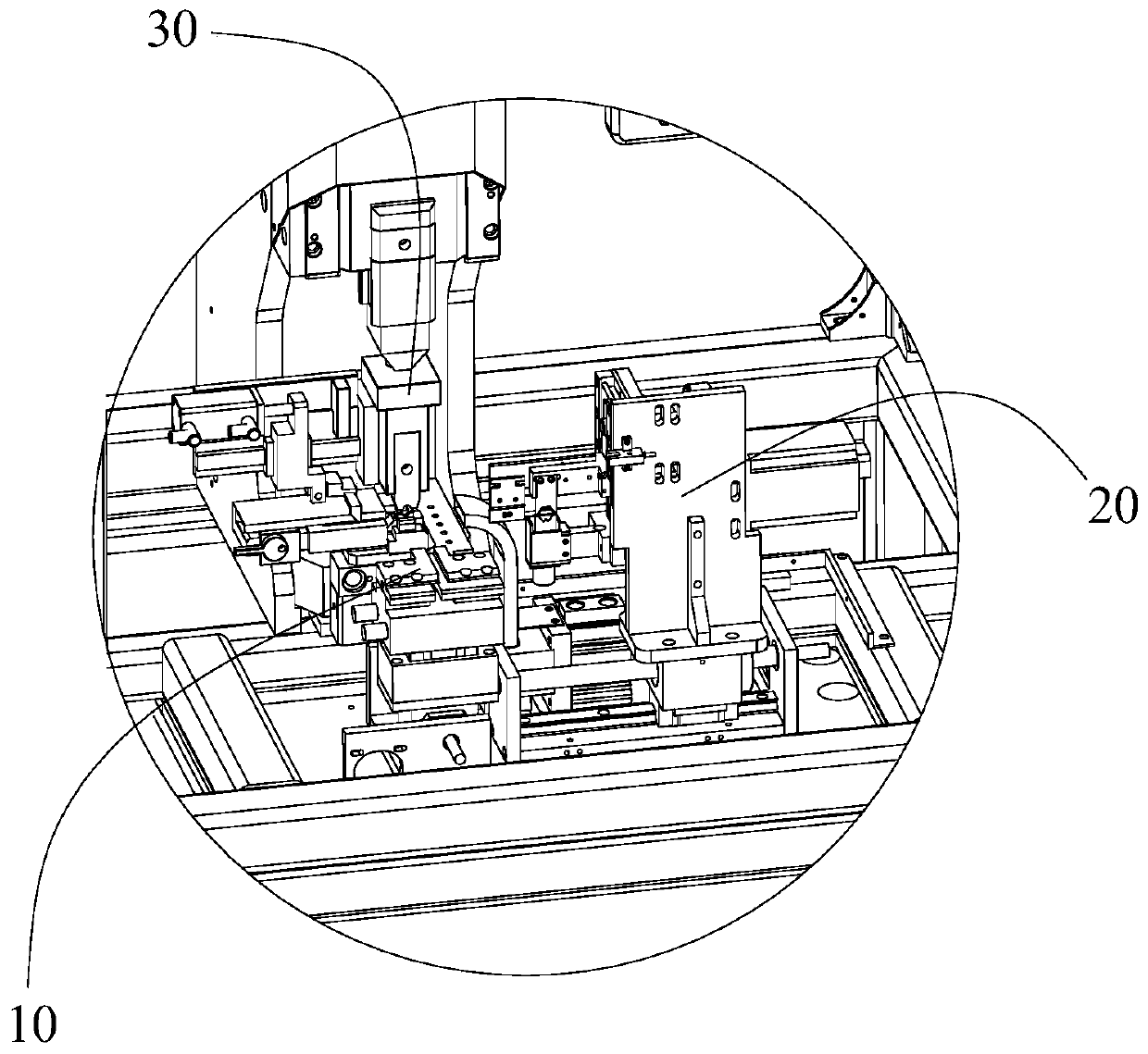

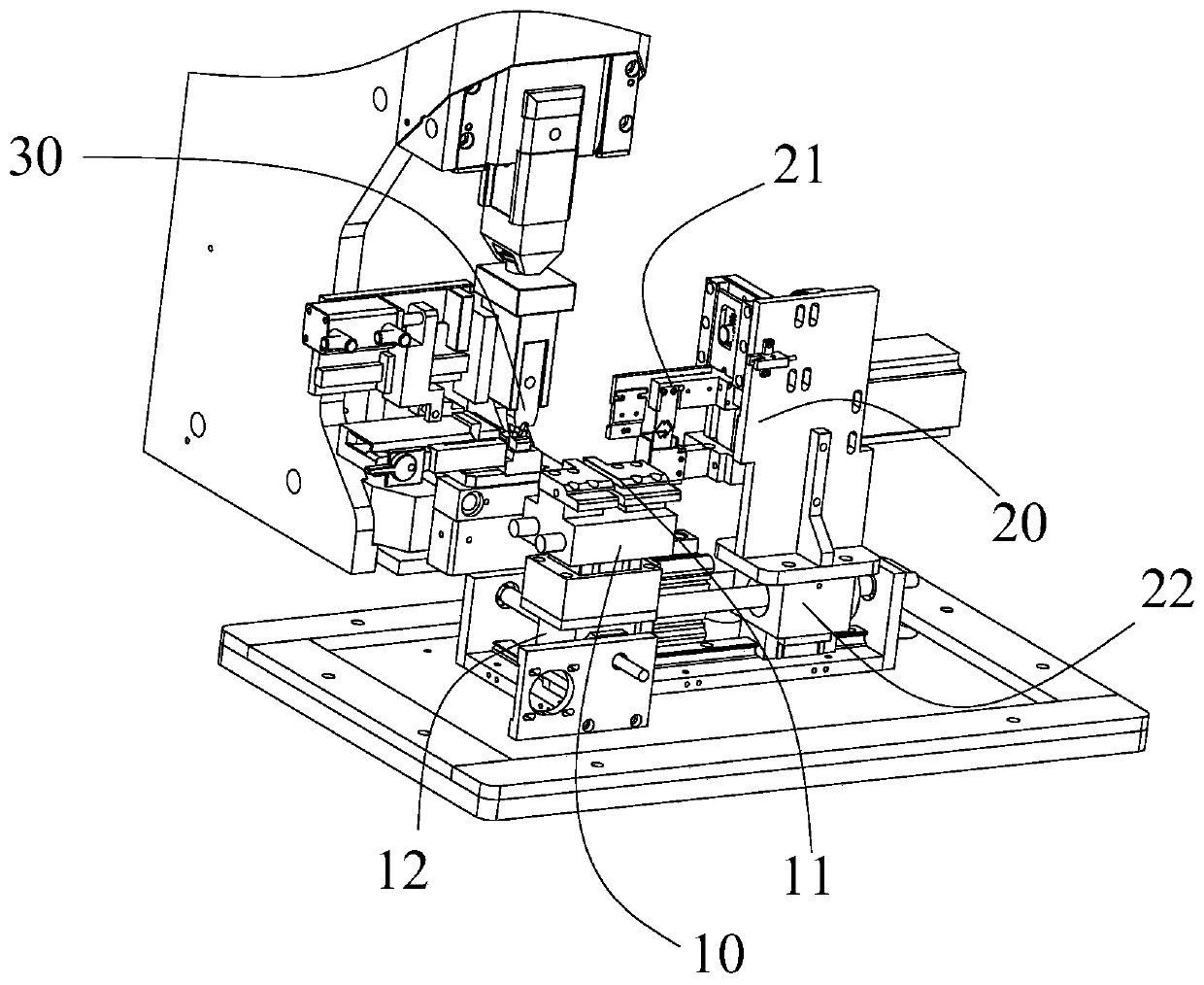

[0037] Such as Figure 1~3 The shown two-wire stripping servo crimping machine includes: a clamping module 10, a cutting and stripping module 20 and a crimping module 30;

[0038] The clamping module 10 is arranged opposite to the crimping module 30 and there is a gap between the two. The clamping module 10 is provided with a clamping assembly 11 for clamping cables and for driving the clamping module 10 toward The direction of the crimping module 30 approaches and moves away from the first drive assembly 12; it should be pointed out here that the first drive assembly 12 is a screw assembly, and the screw assembly only needs the forward and reverse rotation of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com