Method for controlling FBG wavelength based on double-grating structure

A technology of structure control and double grating, which is used in optical waveguides, light guides, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

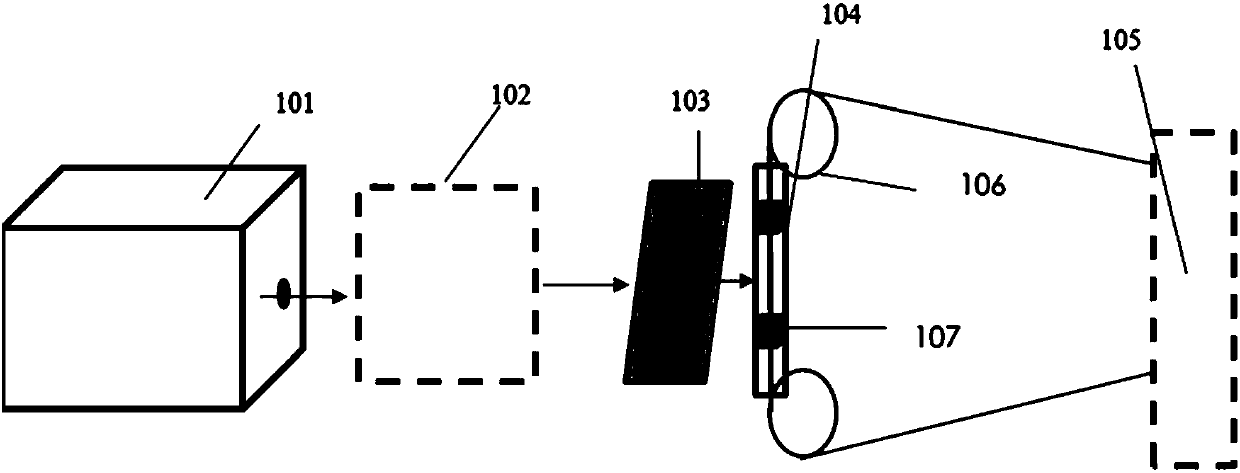

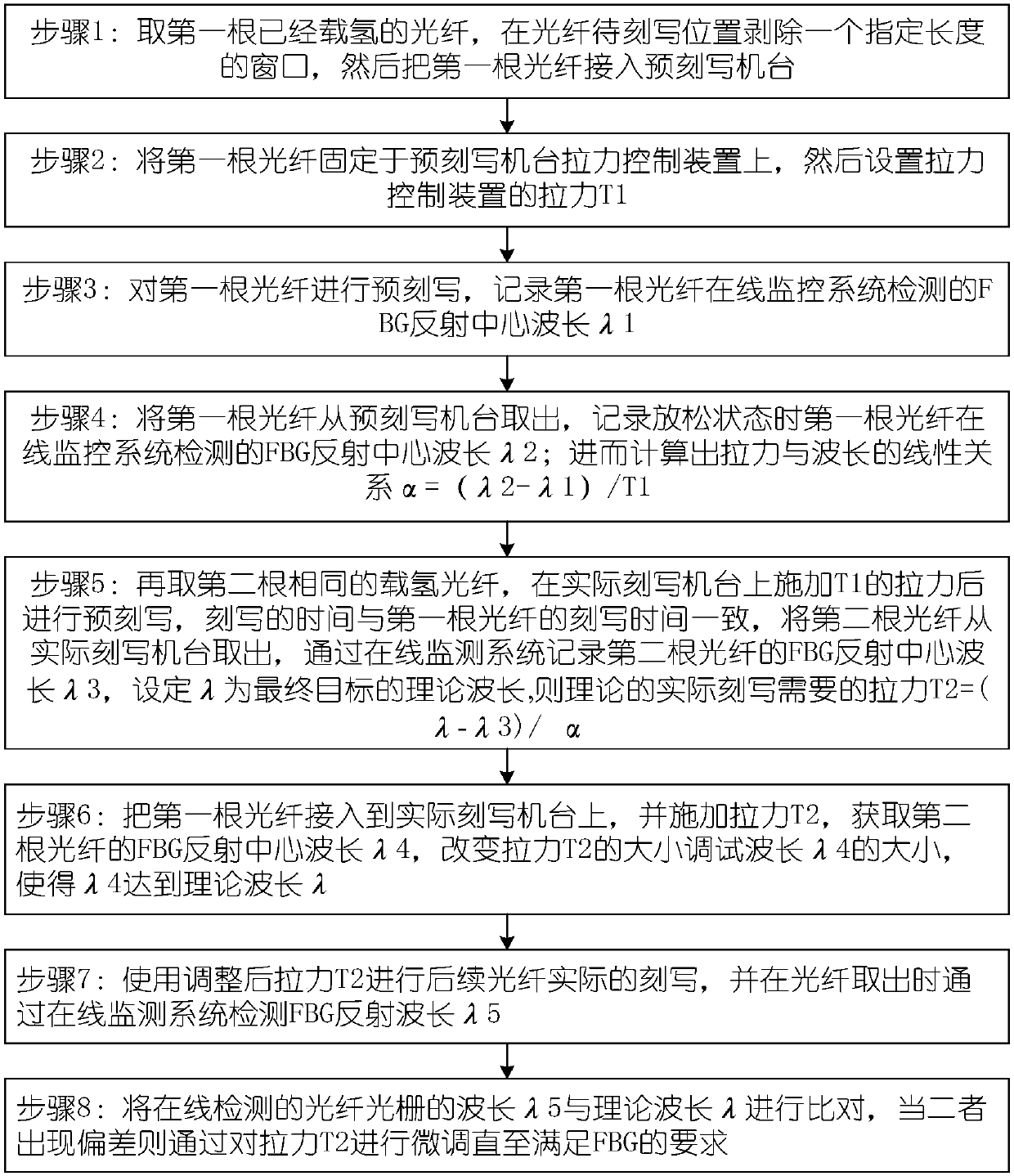

[0030] Such as Figure 1-3 As shown in one of them, the present invention discloses a method for controlling the wavelength of FBG based on a double grating structure. The writing device used includes a laser 101, a shaping optical path 102, a phase mask 103, two grating writing machines 104 and an online monitoring system. 105. The laser light emitted by the laser 101 is sequentially output to two grating writing machines through the shaping optical path 102 and the phase mask 103, wherein one grating writing platform is a pre-writing machine, and the other is an actual writing machine. The two grating writing platforms The machine 104 includes a tension control device 107, which is used to provide an adjustable tension acting on the writing optical fiber. After the fiber grating is fixed, the tension control device 107 can test the tension, and it can also be adjusted by the adjustment knob. The size of the pulling force. Two grating writing machines are connected with onli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com