Calibration Method of Carrier-to-Noise Ratio in High-precision Fixed-Signal-Variable-Noise Mode

A calibration method and carrier-to-noise ratio technology, which can be used in noise figure or signal-to-noise ratio measurement, line transmission components, line transmission monitoring/testing, etc. The effect of reducing calibration error, improving quality and reducing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

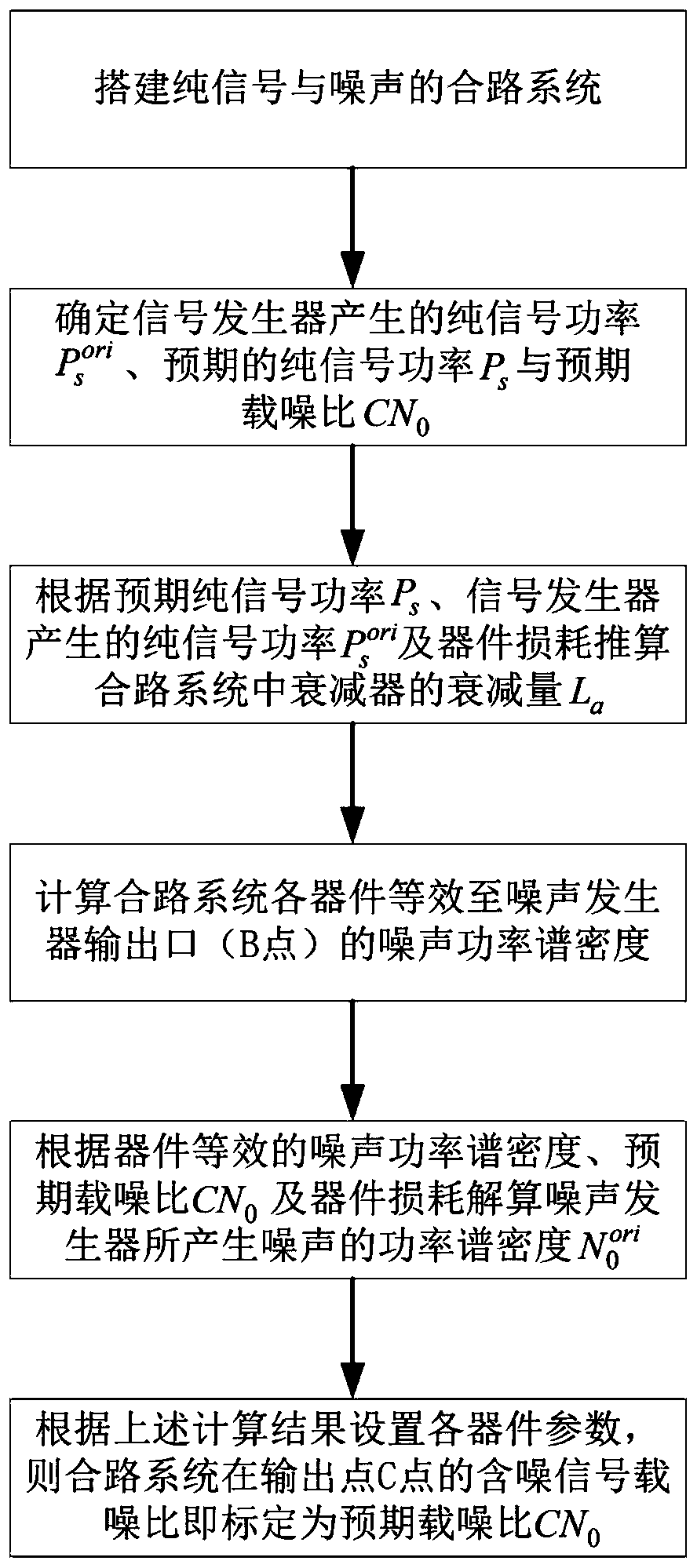

[0036] The carrier-to-noise ratio calibration method of the high-precision fixed signal and noise-changing mode of the present invention, such as figure 1 As shown, follow the steps below:

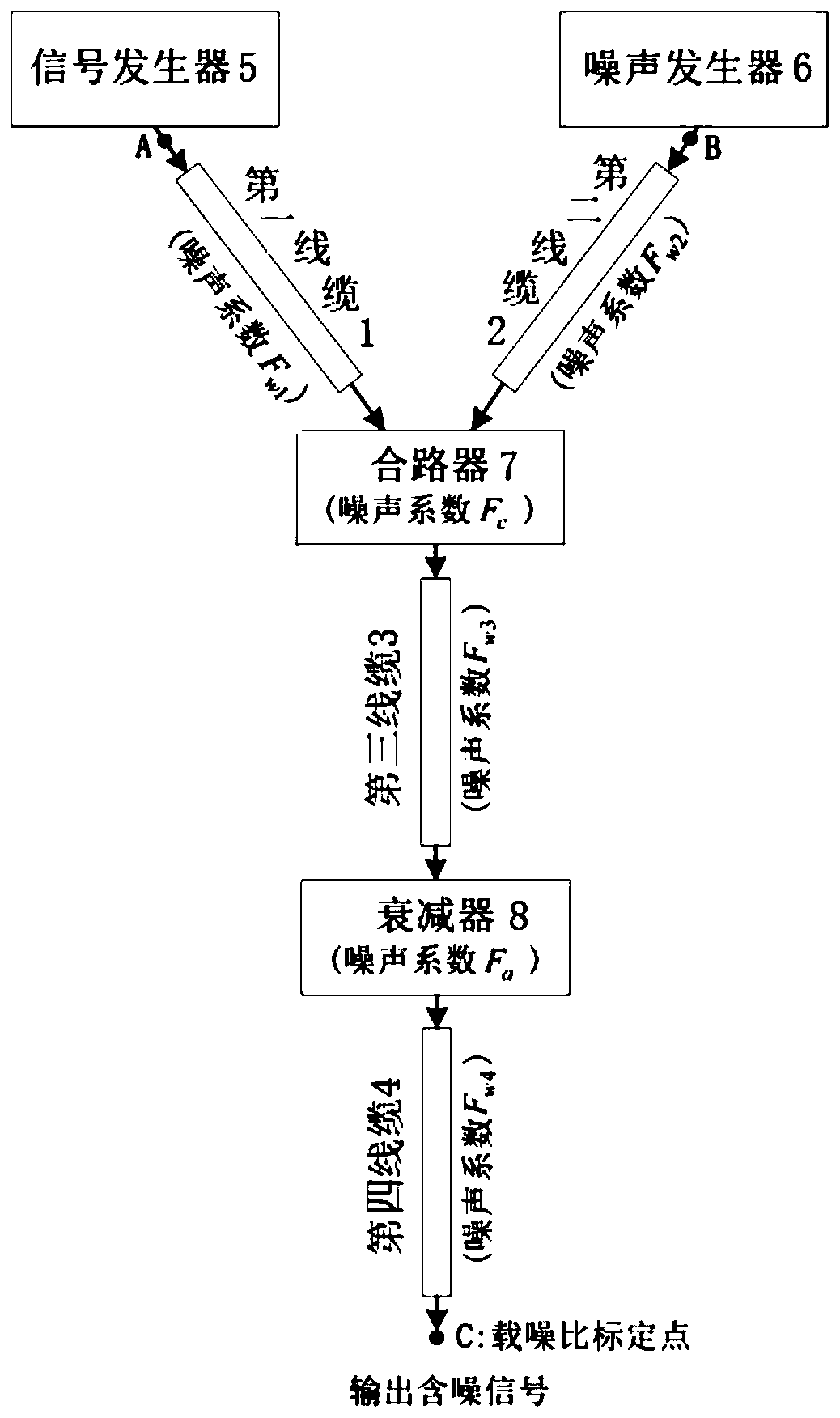

[0037]S1, build a combined system of pure signal and noise, see figure 2 ; The combined system includes a signal generator 5, a noise generator 6, a combiner 7, an attenuator 8, and a coaxial cable, and the output port of the signal generator 5 and the output port of the noise generator 6 pass through the cable respectively Connect with combiner 7, combiner 7 is connected with attenuator 8 through cable; The signal flow in the system is: signal generator 5 produces pure signal (corresponding to figure 2 point A), while the noise generator 6 produces white noise (corresponding to figure 2 point B), the pure signal is input to the combiner 7 through the first cable 1, and the white noise is input to the combiner 7 through the second cable 2, and the noise-containing signal output by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com