Variable-frequency and servo-linkage control system and method for spinning of spinning frame

A technology of linkage control system and spinning frame, which is applied in servo linkage control system, new control transmission system, and frequency conversion field, which can solve the problems of high equipment manufacturing and maintenance costs, large mechanical transmission wear, troublesome process transformation, etc., to improve accuracy , Guaranteed spinning quality, avoiding complexity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

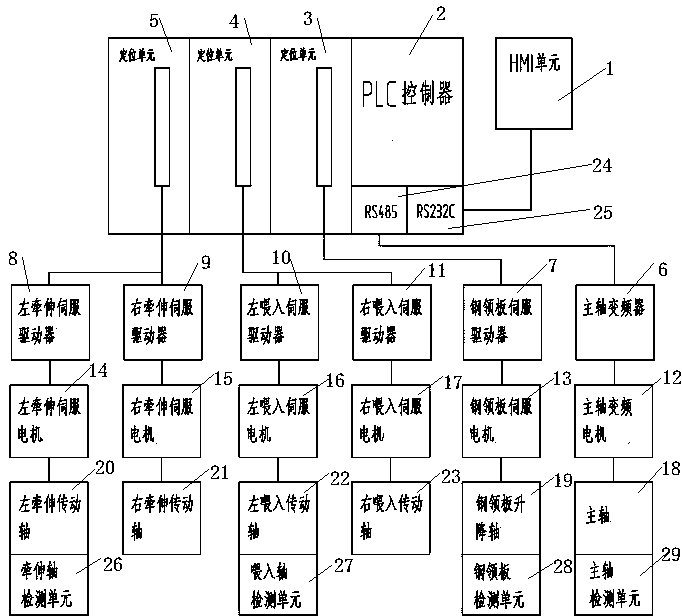

[0032] Examples, as attached figure 1 Shown: a frequency conversion and servo linkage control system for spinning frame spinning, including HMI unit 1, PLC controller 2, three positioning units, spindle frequency converter 6, five servo drives, frequency conversion motor 12, five Servo motors, five transmission shafts, four detection units, the model of the PLC controller 2 is: AFPORC32T, and the PLC controller 2 is electrically connected to the HMI unit 1 .

[0033] The three positioning units are positioning unit 3, positioning unit 4, and positioning unit 5, and the five servo drives are ring plate servo drive 7, left drafting servo drive 8, right drafting servo drive 9, and left feeding servo drive 10. Right feeding servo driver 11, five servo motors are ring plate servo motor 13, left drafting servo motor 14, right drafting servo motor 15, left feeding servo motor 16, right feeding servo motor 17, The five transmission shafts are the main shaft 18, the ring plate lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com