Automobile front door handle ejecting mechanism

A technology of ejecting mechanism and front door, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of poor reliability, products that are easy to be pulled, and products that cannot be ejected, and achieves the effect of high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

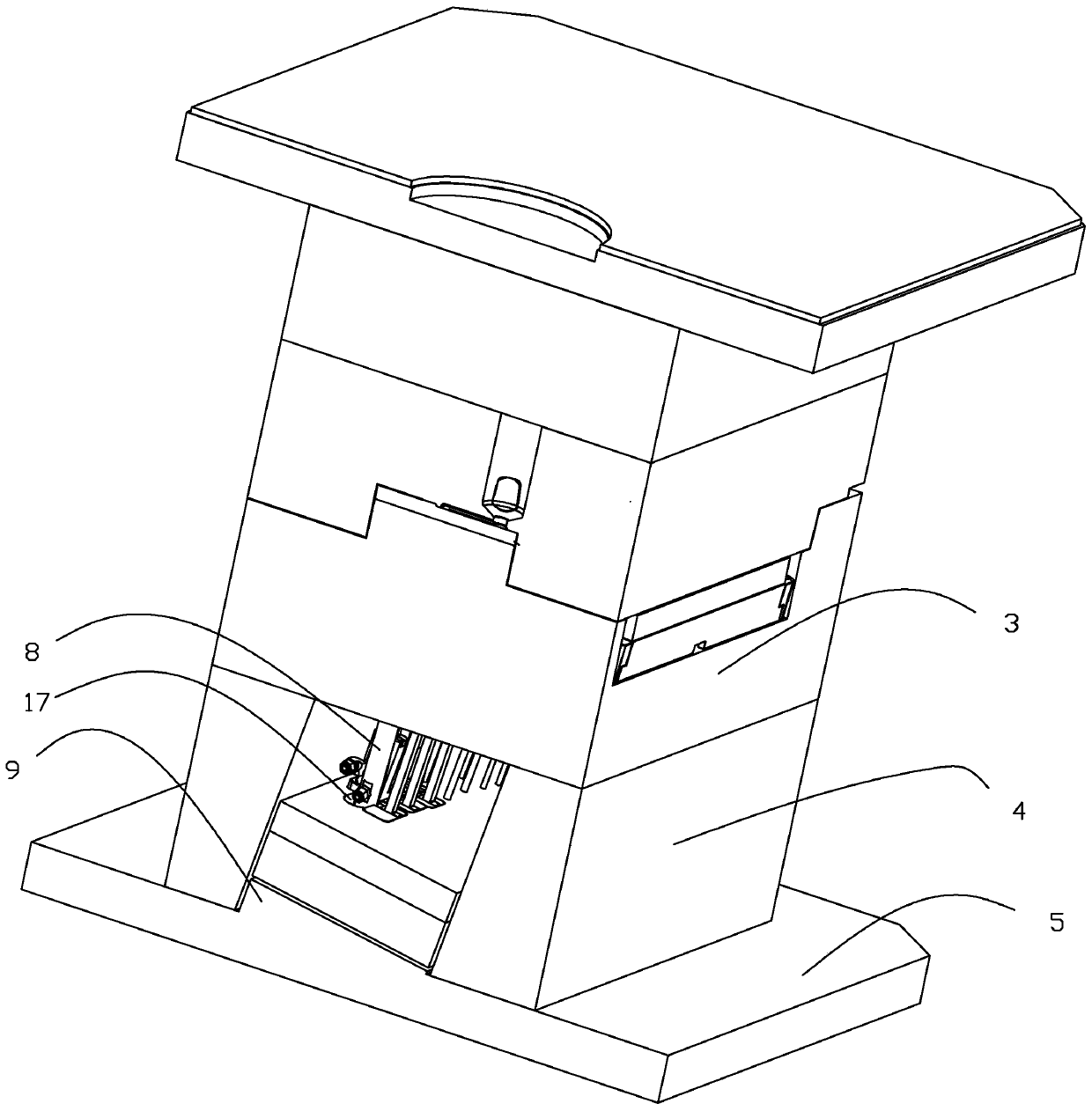

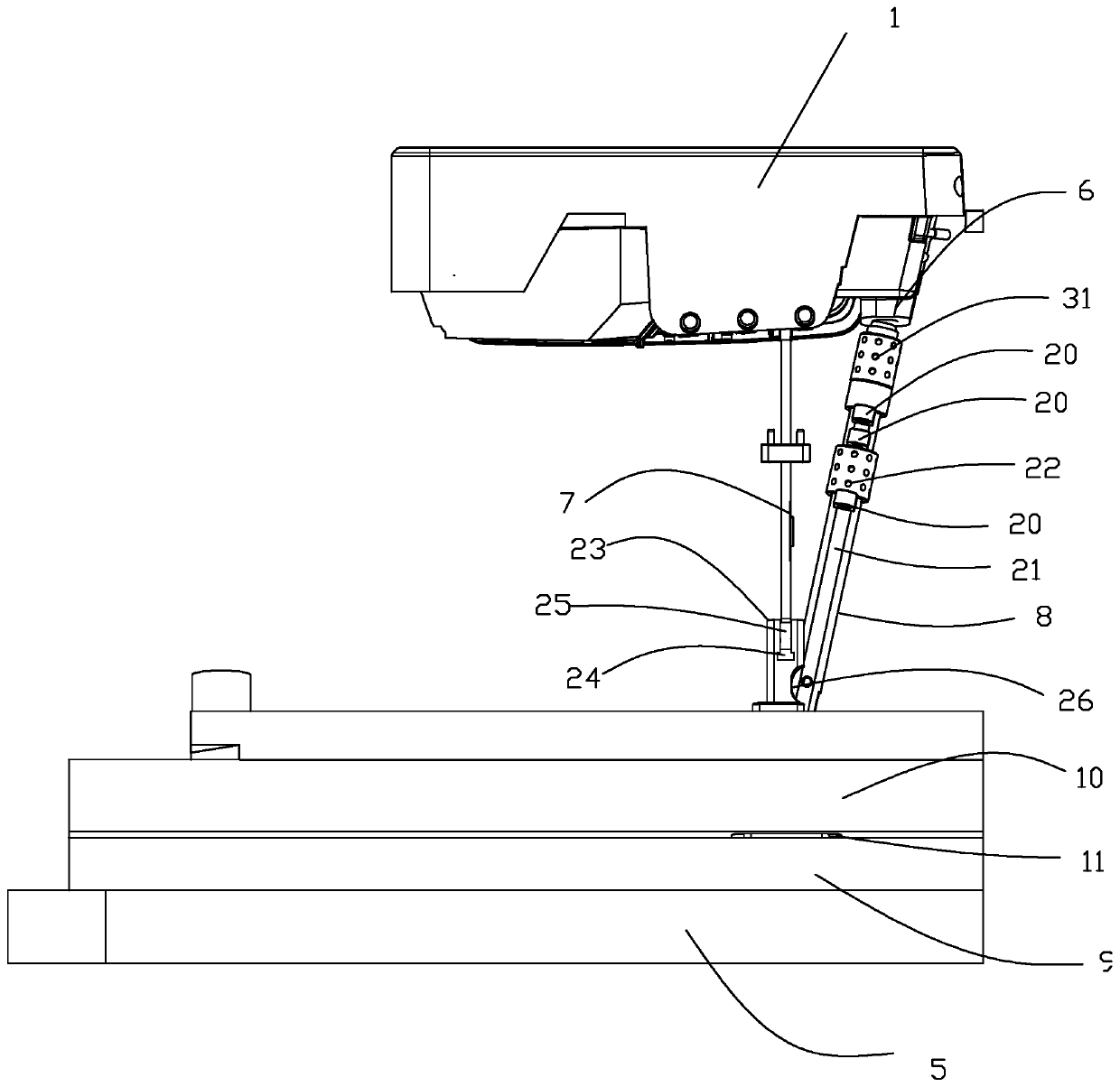

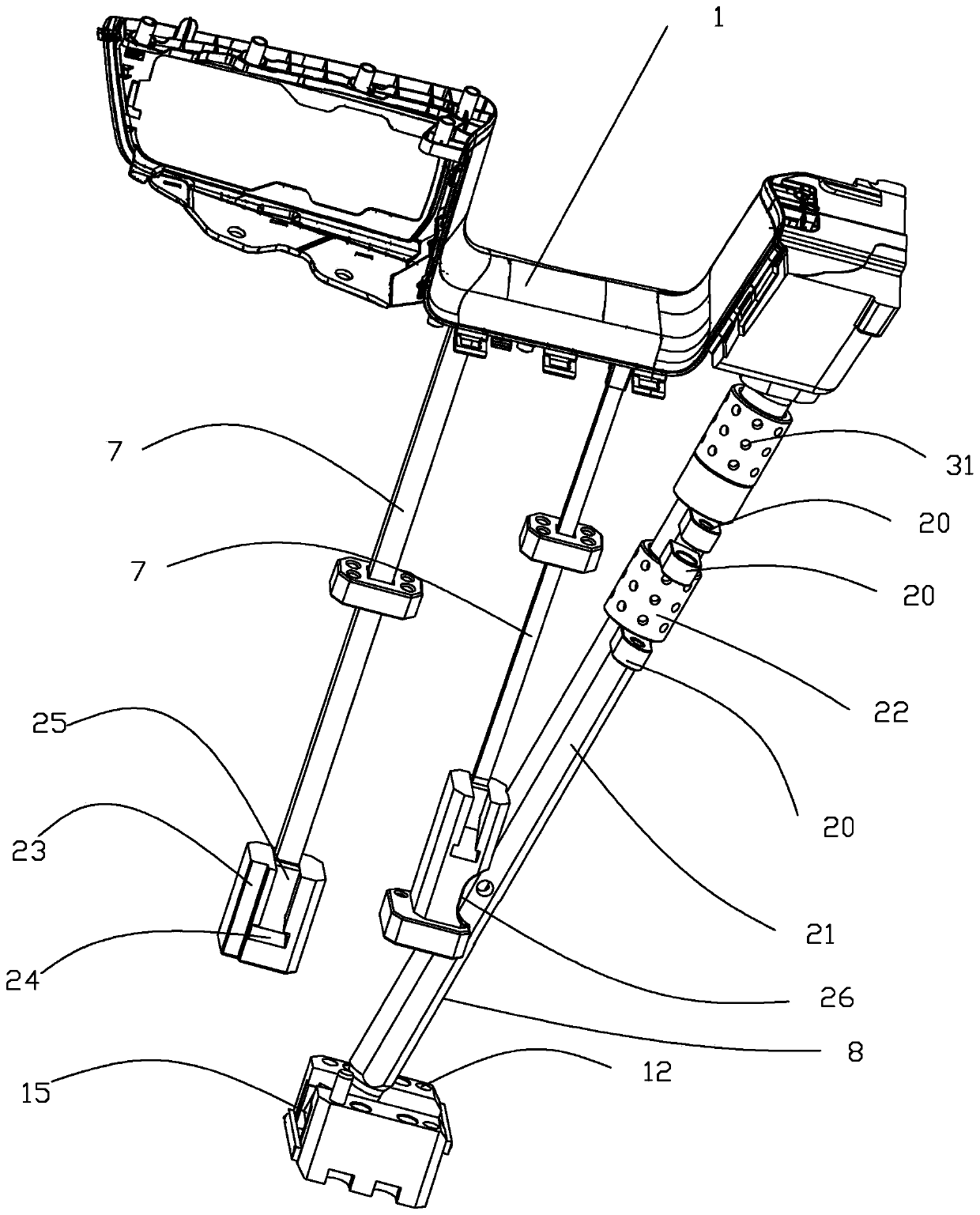

[0023] As shown in the figure, the present invention provides an automobile front door handle ejection mechanism, which includes a product 1, a lower template 3, a mold foot 4, a bottom plate 5, at least two ejector rods 7, an inclined guide rod 8 and a thimble plate 10. The right side of the product 1 is provided with a groove 2, the side of the groove 2 is a slope, the top of the groove 2 is provided with an undercut 32, and the lower template 3 is provided with a groove 2 for simultaneous molding. The mold core 6 on the side and the top of the groove 2, the mold foot 4 is located between the lower template 3 and the bottom plate 5, the upper surface of the bottom plate 5 is provided with a protrusion 9 protruding from the upper surface of the bottom plate 5, and the Both the upper surface of the protrusion 9 and the upper surface of the ejec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com