Reaction kettle for producing stone-like coating

A technology of reaction kettle and real stone paint, which is applied in the direction of chemical/physical/physicochemical fixed reactors, dissolution, mixers, etc., can solve the problem of increasing the diameter of lumpy adhesives, forming a glued film, and the fact that real stone paint is prone to knots. block and other problems, to increase the effect of scraping and rapping, prevent clogging, and increase the effect of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

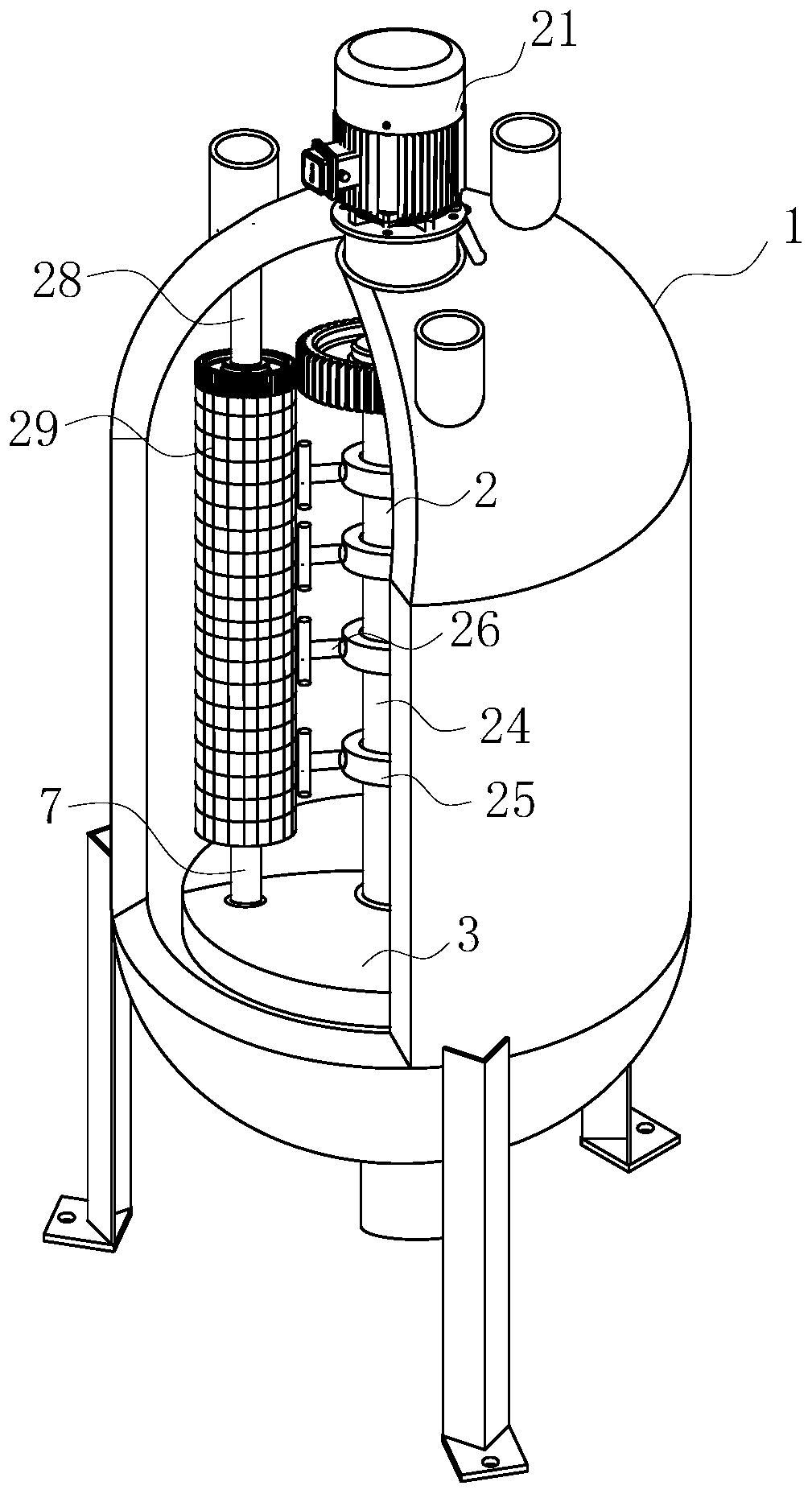

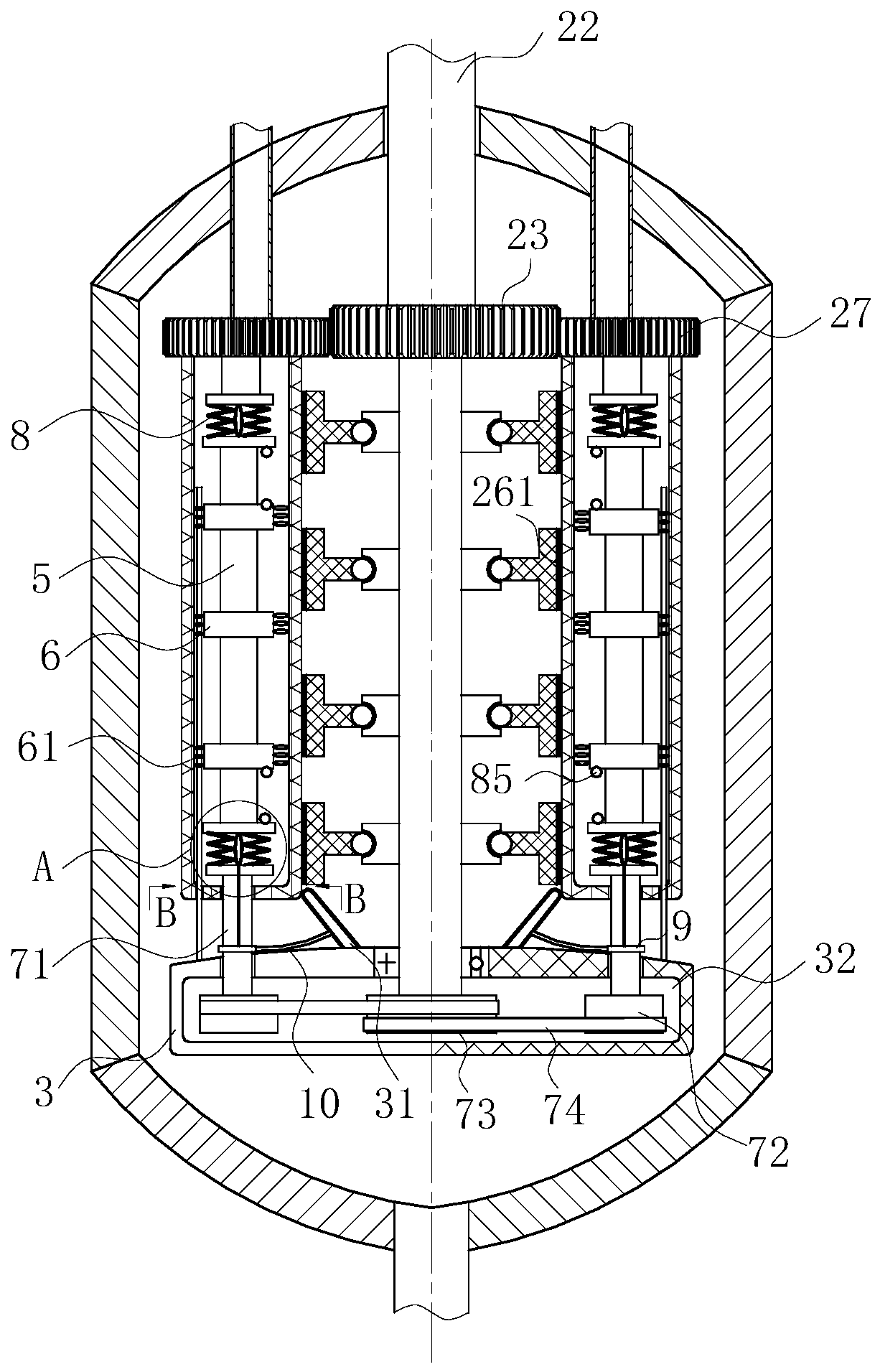

[0021] use Figure 1-Figure 4 A reaction kettle for producing real stone paint according to an embodiment of the present invention is described as follows.

[0022] Such as Figure 1-Figure 3 As shown, a reaction kettle for producing real stone paint according to the present invention includes a reaction tank 1; a raw material stirring and mixing device 2 is arranged inside the reaction tank 1, and a slurry discharge port is provided at the bottom of the reaction tank 1, and The top raw material inlet of the reaction tank 1; the stirring and mixing device 2 includes a stirring motor 21, a drive shaft 22, a driving gear 23, a stirring shaft 24, a rotating disk 25, a vibrating hammer 26, a driven gear 27, a cavity rotating shaft 28 and Elastic filter screen cylinder 29; the output end of the stirring motor 21 is connected with a drive shaft 22, and the bottom end of the drive shaft 22 passes through the reaction tank 1 and is connected with a driving gear 23; the bottom end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com