Damp-proof and dehumidifying method for 10KV box-type transformer substation

A technology of box transformer and dehumidifier, which is applied in the cooling/ventilation of substation/switchgear, substation/power distribution device shell, substation/switch layout details, etc., which can solve the problems that are difficult to implement, difficult to ensure assembly quality and electrical safety parameters, etc. problems, to achieve the effect of prolonging the service life, ensuring safe and stable operation, and reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

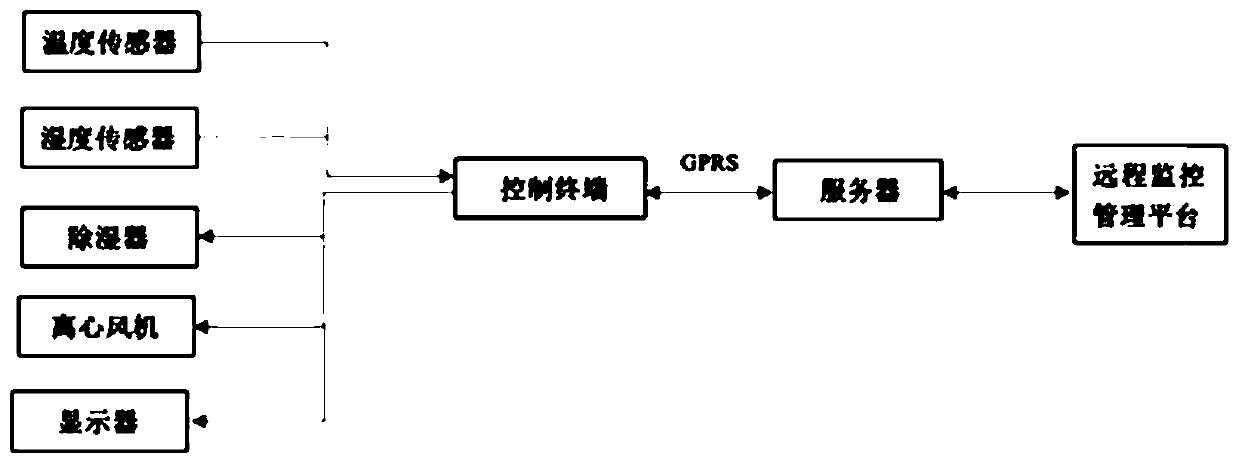

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0038] figure 1 and figure 2 Among them, the technical solution of the present invention provides a moisture-proof dehumidification method for a 10 kV box-type substation, including dehumidifying the air in the cabinet, and its invention points are:

[0039] A dehumidification module is installed in the closed box-type cabinet of the box-type transformer;

[0040] Inside and outside the closed box-type cabinet of the box-type substation, there are corresponding temperature and humidity sensors respectively;

[0041] At least one drain line on the closed cabinet;

[0042] Install an exhaust fan on the closed box-type cabinet;

[0043] The dehumidification module, the corresponding temperature and humidity sensor and the exhaust fan are connected with a local control terminal module;

[0044] The local control terminal module is connected with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com