Simulation method for warehouse AGV quantity evaluation

A simulation method and quantity technology, which is applied in the simulation field of warehouse AGV quantity evaluation, can solve the problems of waste of transportation capacity, failure to meet transportation volume requirements, rough estimation, etc., and achieve the effect of saving enterprise cost, reducing calculation time, and balancing the relationship.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

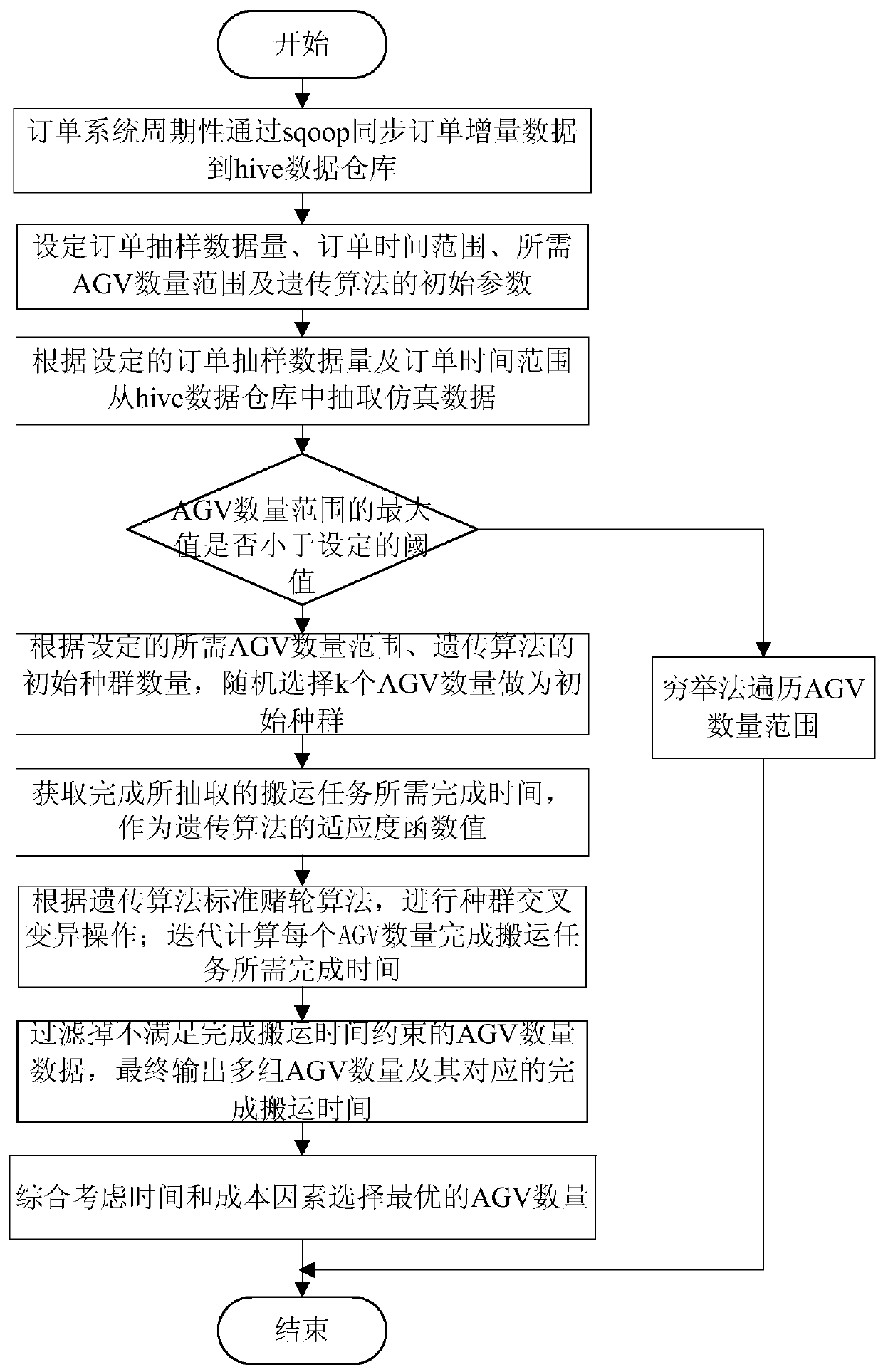

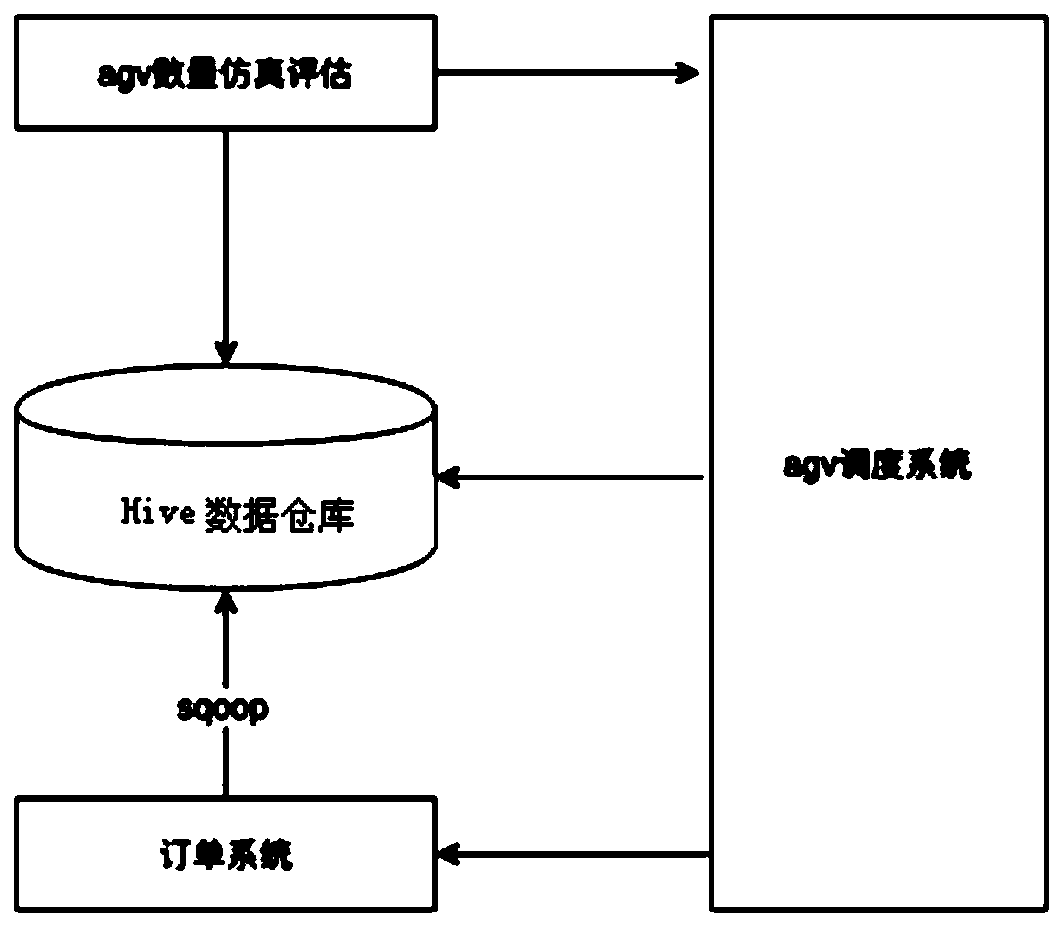

[0022] In this embodiment, a simulation method for evaluating the quantity of warehouse AGVs, such as figure 1 and 2 shown, including the following steps:

[0023] Step 1. The order system periodically synchronizes the incremental order data to the hive data warehouse through sqoop;

[0024] Step 2. Set the order sampling data volume, order time range, required AGV quantity range, initial population size and maximum number of iterations of the genetic algorithm;

[0025] Step 3. According to the set order sampling data volume and order time range, the simulation data is extracted from the hive data warehouse, that is, the handling tasks that the AGV needs to complete; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com