Modular bridge expansion joint with horizontal swing supporting cross beams

A technology for supporting beams and expansion joints, which is applied in the field of bridge expansion joints, can solve problems such as difficult installation, shortened service life of bridges, and inflexible use, so as to improve shock absorption and isolation performance, alleviate multi-angle impacts, and save manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

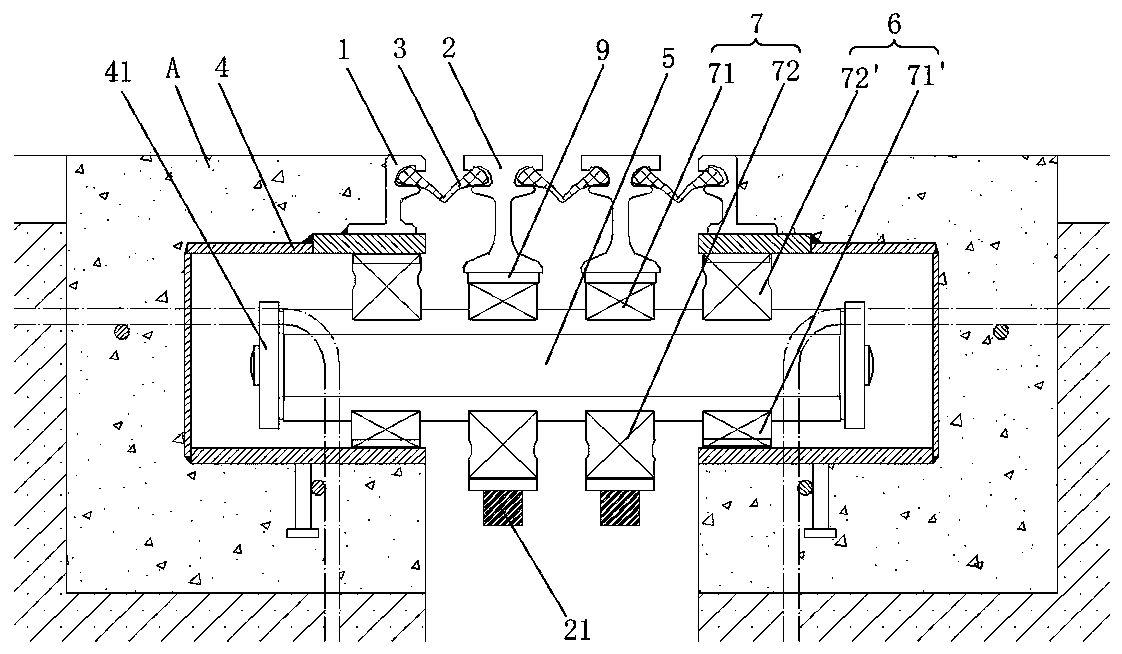

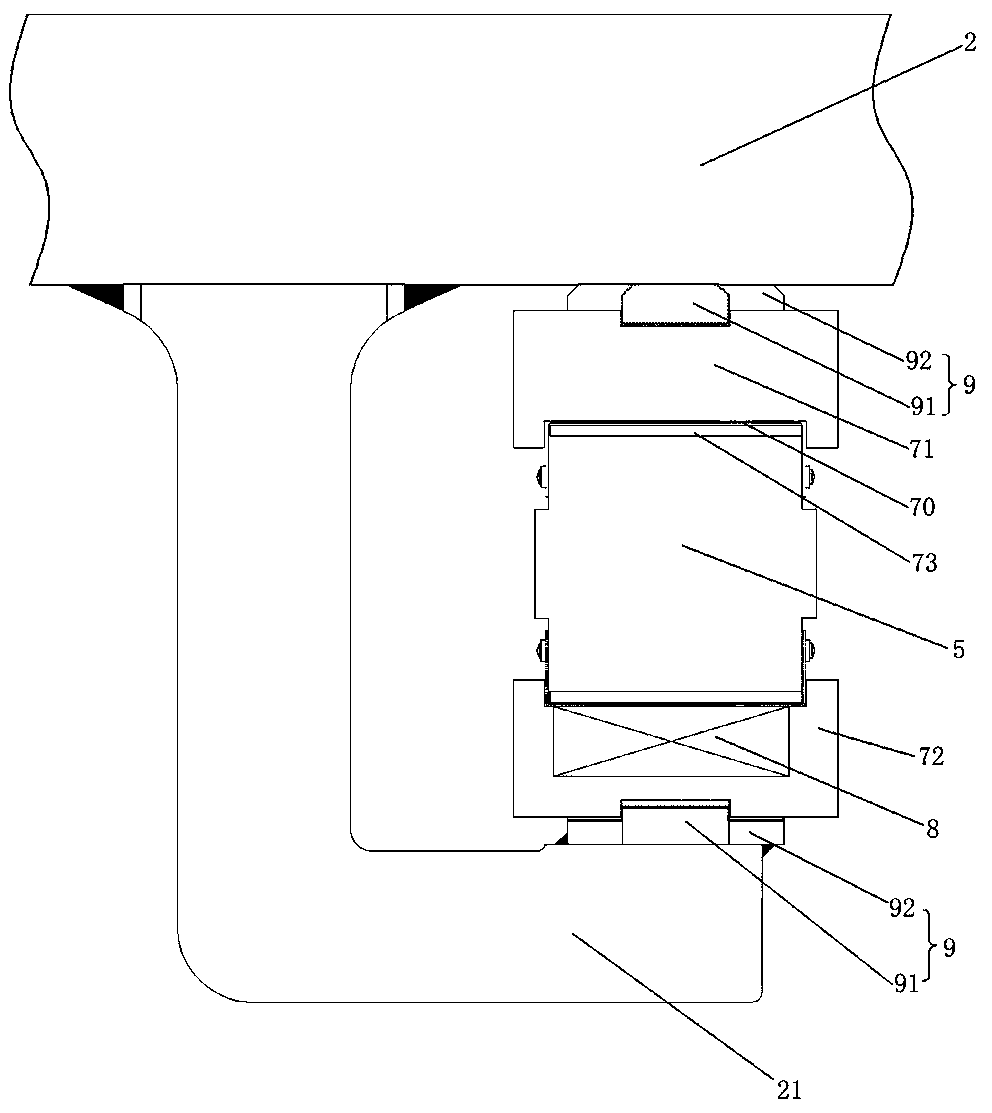

[0024] The structure and working principle of a modular bridge expansion joint provided by the present invention with swing support beams will be further described in detail below with reference to the accompanying drawings.

[0025] see figure 1 , is a structural schematic diagram of a modular bridge expansion joint provided by the present invention with a swing support beam. The modular bridge expansion joints with swinging support beams comprise a pair of side beams 1 and at least one middle beam 2 arranged between the side beams 1, the side beam 1 and the middle beam 2 and the adjacent middle beam 2 A waterstop 3 is set between them, and a displacement control box 4 is set at the lower part of the side beam 1. The displacement control box 4 is used to place the end of the support beam 5. The support beam 5 has an oblique angle to the axis of the expansion joint, and the end of the support beam 5 The upper part is defined in the displacement control box 4 by the first swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com