Low-rigidity quick-limiting rear shock-insulation buffer block for automobile

A buffer block, low stiffness technology, applied in the direction of vehicle parts, the connection between the body and the frame, transportation and packaging, etc., can solve the problems of large product compression and slow limit, achieve small wear area and improve service life. , the effect of reducing the amount of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are the Some, but not all, embodiments are invented.

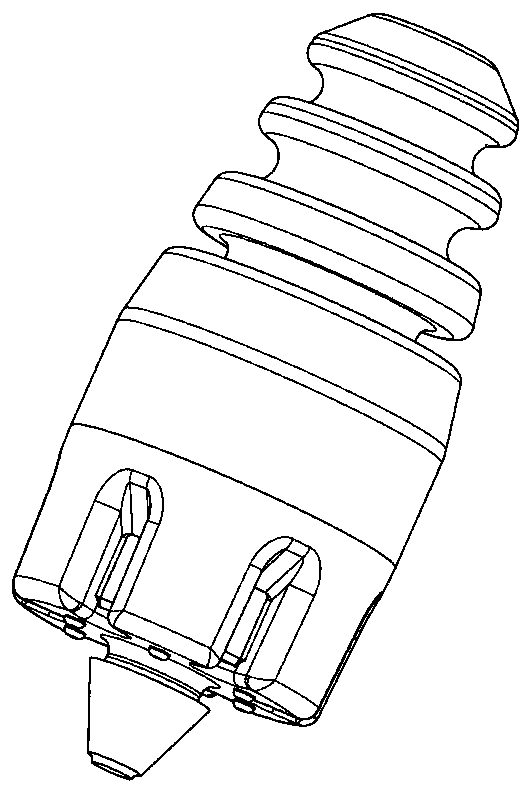

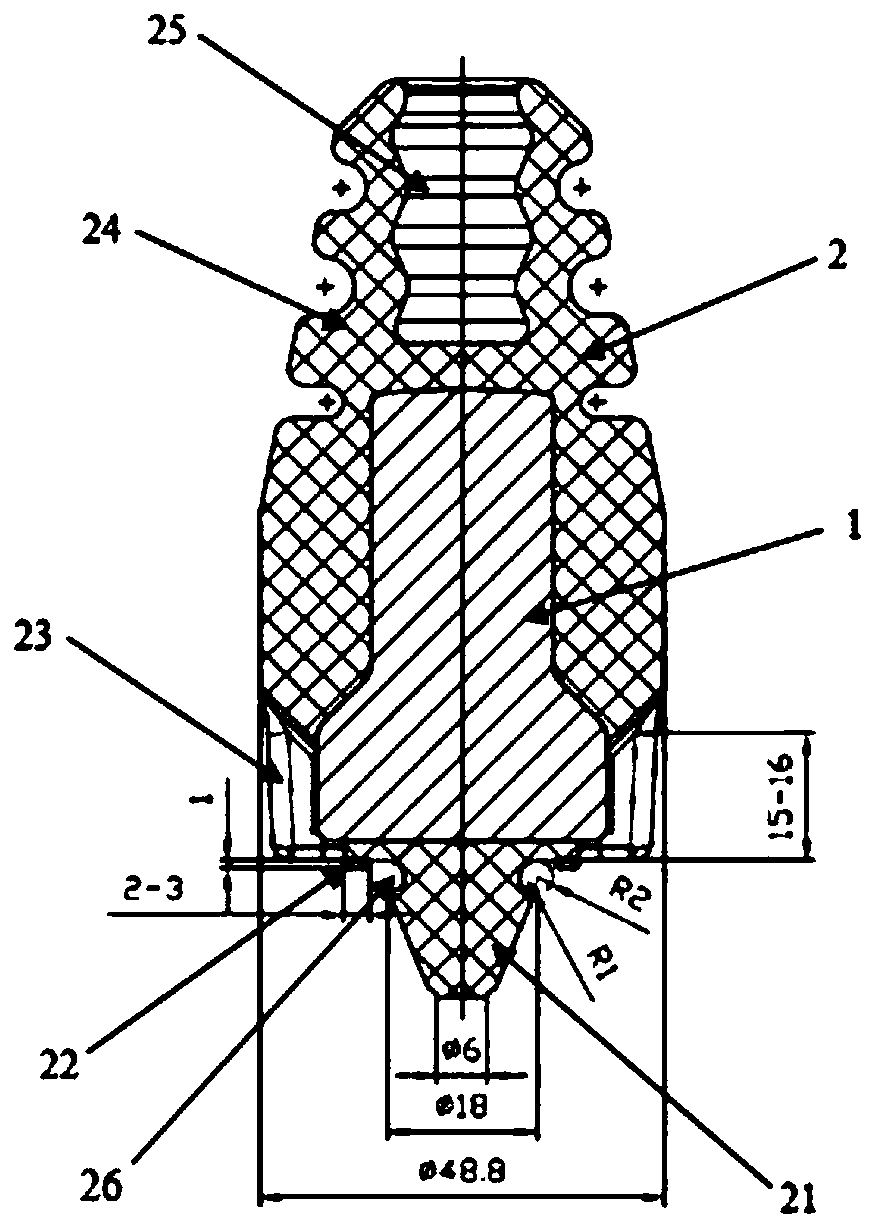

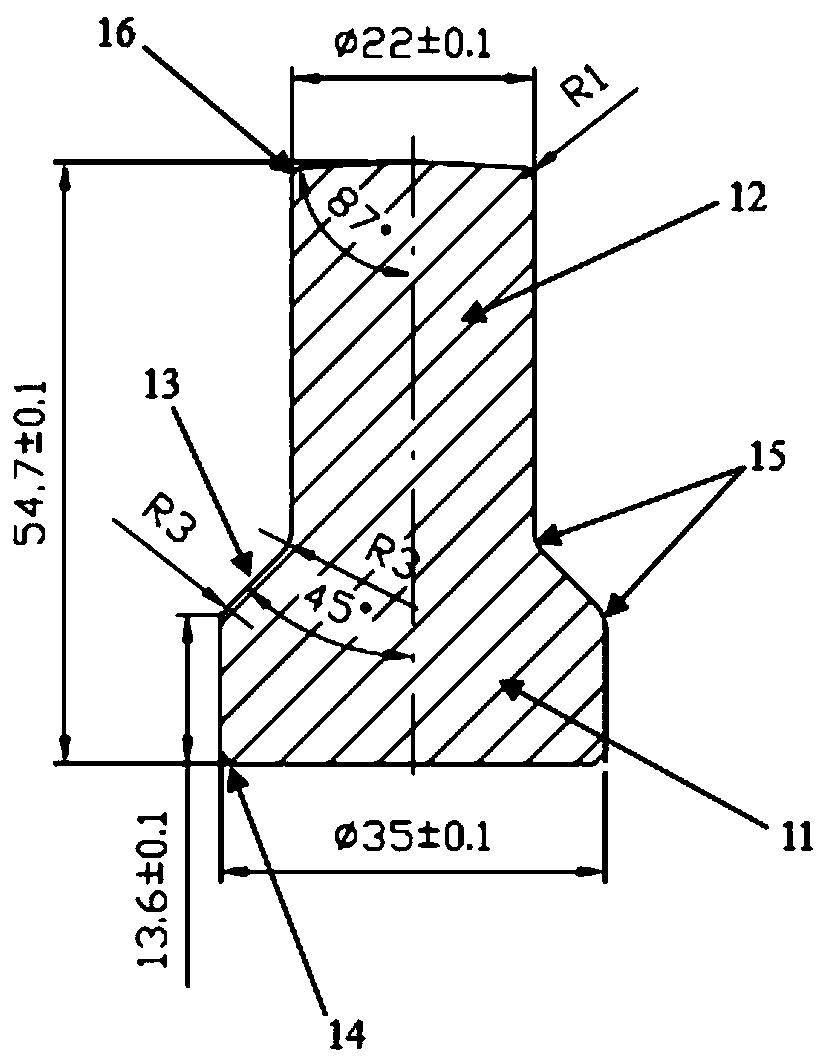

[0024] A low-rigidity quick-limit automobile rear shock-isolation buffer block, such as Figure 1-3 As shown, it is characterized in that it is composed of a limit frame 1 and a vulcanized rubber 2; the limit frame 1 is an inverted "T"-shaped cylinder, and the horizontal part 11 of the inverted "T"-shaped cylinder has a length of φ35± 0.1mm and a height of 13.6±0.1mm, the upper and lower ends have a large chamfer 13 and a small chamfer 14 respectively, and the angle of the large chamfer 13 is 45°, which are respectively connected to the upper end of the horizontal part 11 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com