Actuator

A technology for actuators and moving bodies, applied in electrical components, electromechanical devices, etc., can solve problems such as difficult adhesives, filling into gaps, and reduced bonding strength of coils and coil cages, and achieve the effect of not easily damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

[0126] In the above-mentioned embodiment, the permanent magnets (the first permanent magnet 71 and the second permanent magnet 72) are provided on both sides of the first direction Z relative to the coil 5, but it is also possible to apply the present invention to One side of the first direction Z of 5 is provided with an actuator of a permanent magnet.

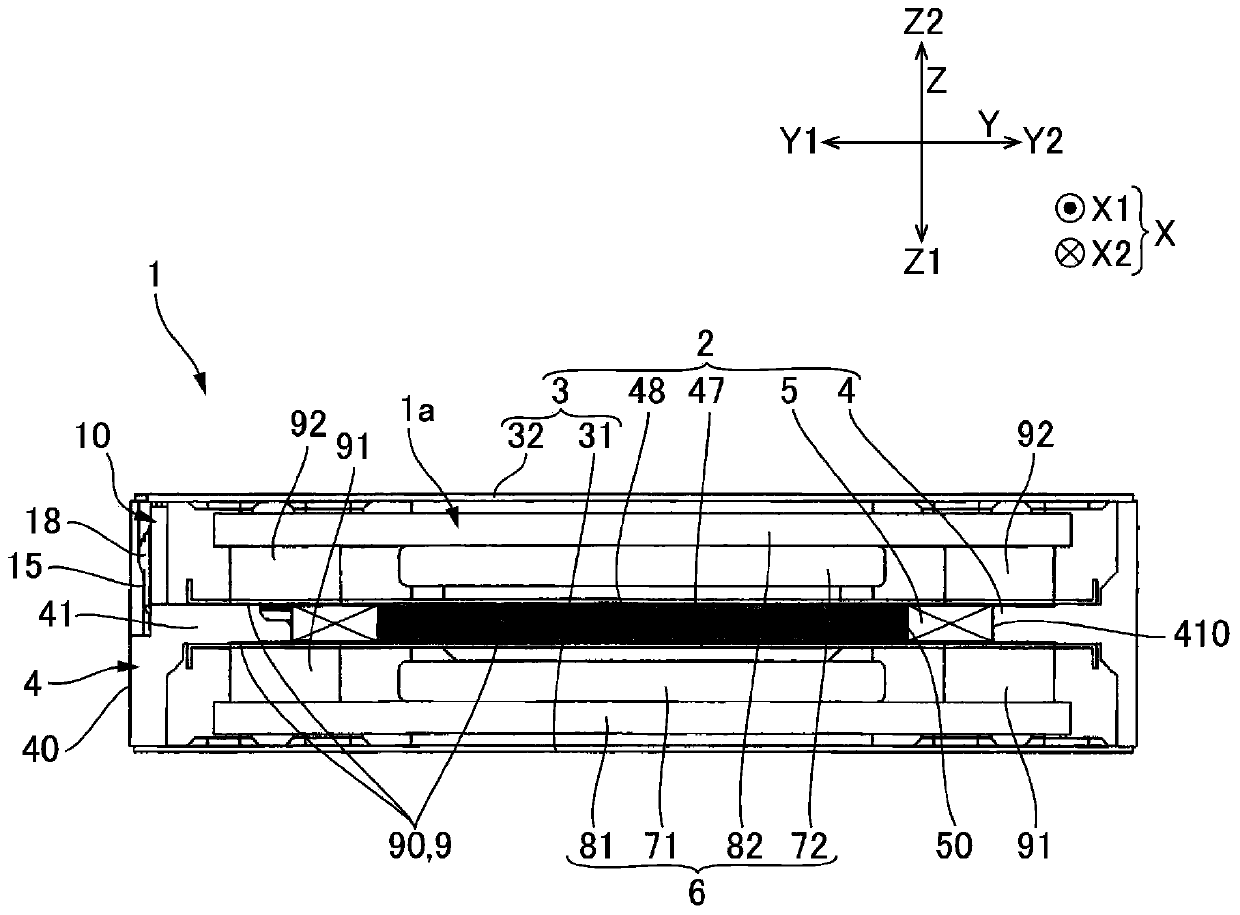

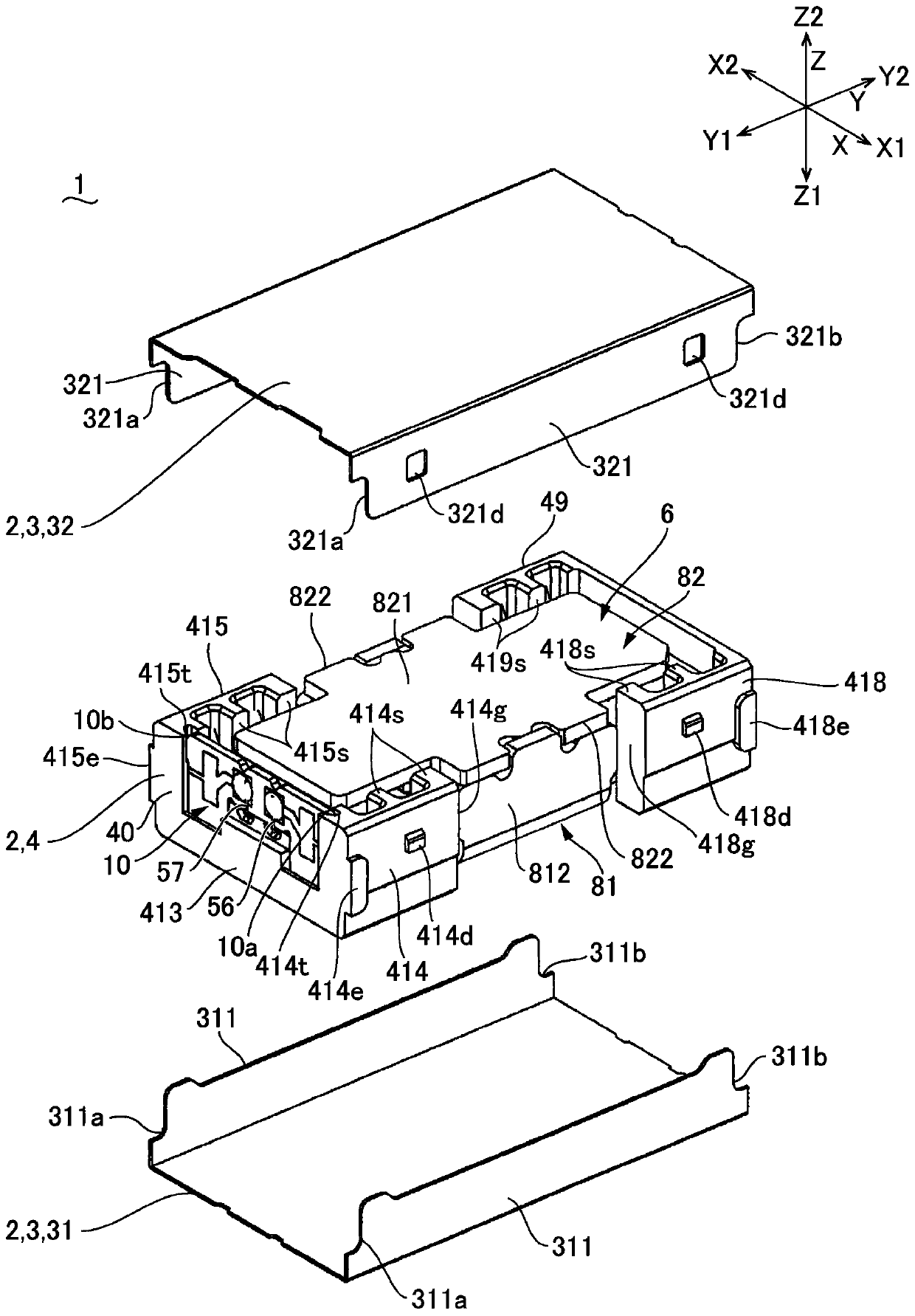

[0127] In the above-mentioned embodiment, the coil holder 4 and the coil 5 are provided on the support body 2, and the permanent magnets (the first permanent magnet 71 and the second permanent magnet 72) and the yokes (the first yoke 81 and the second The yoke 82) is provided on the movable body 6. However, the structure using the first plate 47 and the second plate 48 or the structure for providing slack on the power supply substrate 10 can also be applied to provide the coil holder 4 and the coil 5 on the movable body 6, and permanently The magnets (the first permanent magnet 71 and the second permanent magnet 72 ) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com