LED light source module and intelligent lamp cap

A technology of LED light sources and modules, applied in the field of LED lighting, can solve the problems of poor light distribution effect and inability to directly transform, and achieve low cost, meet the needs of outdoor lighting, and easy and precise light distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

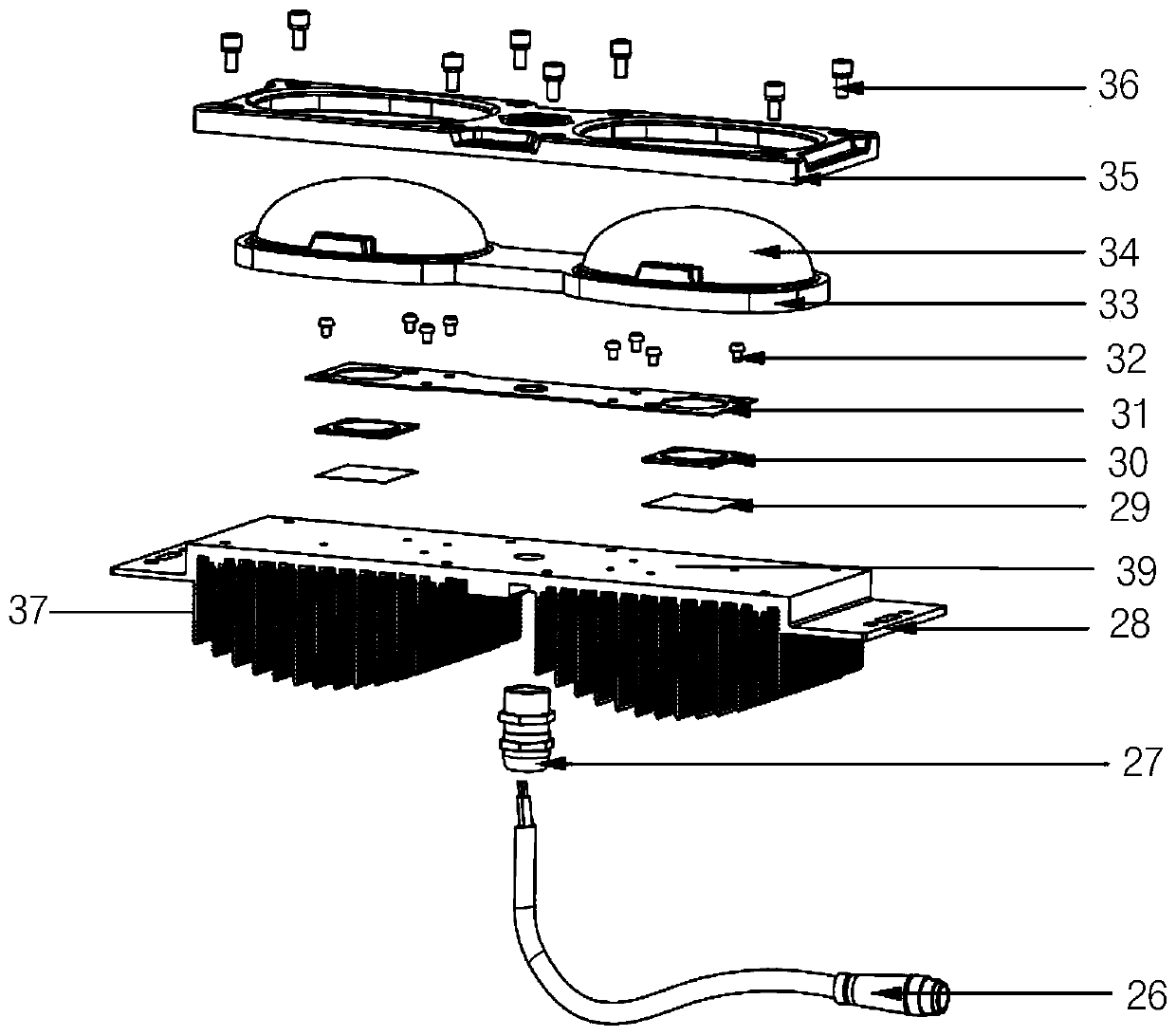

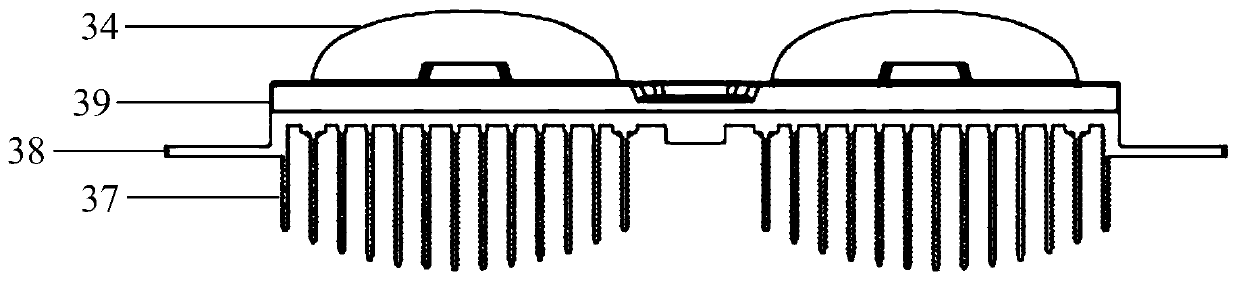

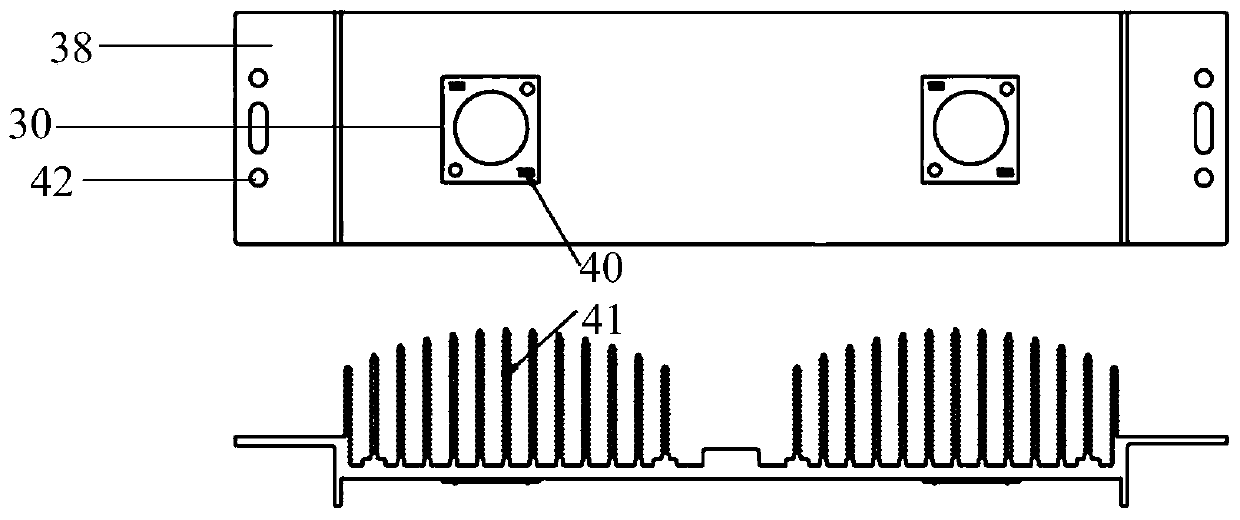

Embodiment 1

[0108] The smart lamp head of this embodiment includes: a first integrated module, the first integrated module includes a first module liner 5 and a camera 3, the first module liner 5 is provided with an opening, and the camera 3 is embedded in the The opening of the first module liner 5; the second integrated module, the second integrated module includes: the second module liner 16 and the intelligent control device 4; the third integrated module, the third integrated module includes: the third module The backing plate 17 and the horn 8; and the LED light source module 9, the lamp housing upper cover 1, the lamp housing base 32, the camera bracket 2, the integrated antenna box 6, the horn installation box 7 and the horn cover 10. When assembling the smart lamp holder, the first integrated module, the second integrated module and the third integrated module are arranged in the lamp housing, and the first module liner 5, the second module liner 16, and the third module liner 17 a...

Embodiment 2

[0113] The only difference between Embodiment 2 and Embodiment 1 is that in the LED light source module 9, the ratio of the shorter length to the longer length of the two adjacent heat dissipation fins 37 is 90% to 92%.

Embodiment 3

[0115] The only difference between Embodiment 3 and Embodiment 1 is that in the LED light source module 9, the ratio of the shorter length to the longer length of the two adjacent heat dissipation fins 37 is 93%-95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com