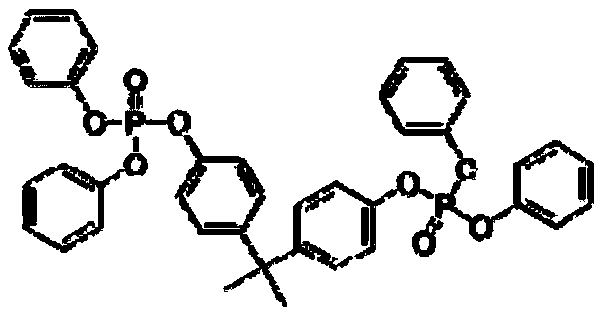

Preparation method of bisphenol A-bis(diphenyl phosphate)

A technology of diphenyl phosphate and phenol, which is applied in the field of bisphenol A-bis preparation, can solve problems affecting human health and life, and achieve the effects of reduced impurity content, stable method, and increased purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

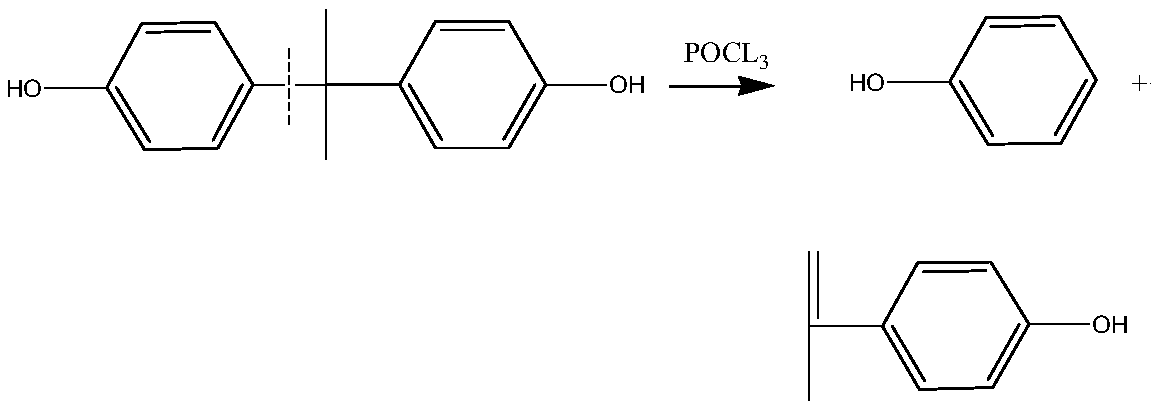

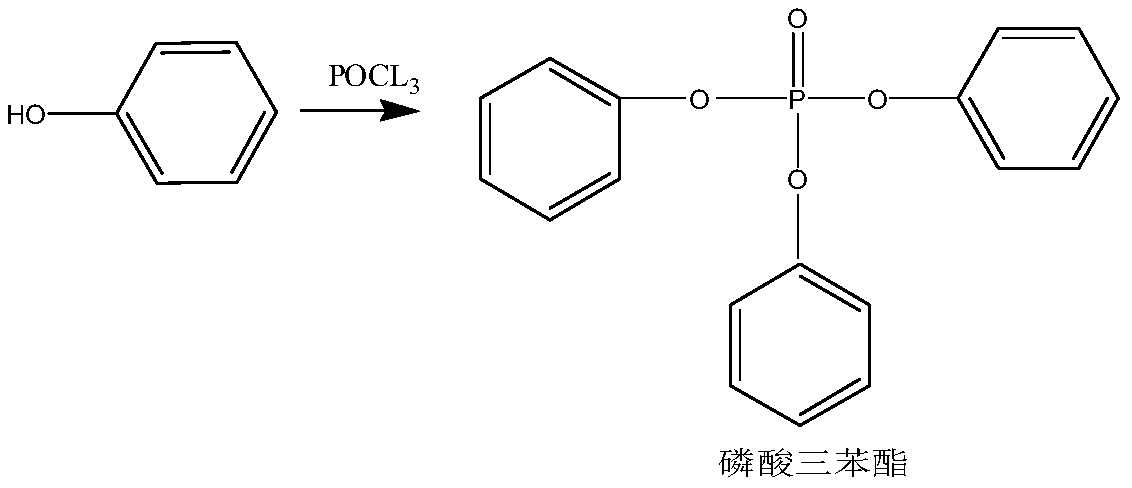

Method used

Image

Examples

Embodiment 1

[0048] 1. Esterification reaction: add 150g (0.66 moles) of bisphenol A, 15g catalyst magnesium chloride, and 200g xylene into a four-neck flask, raise the temperature to 90-100°C, and slowly add 335g (2.18 moles, bisphenol The molar ratio of A to phosphorus oxychloride is 1: 3.3), and the dropwise addition is completed in 2 hours. After the addition, it is kept at 105-110°C for 2.5 hours. Distill at 2-3KPa until the temperature is 130-140°C, stop the distillation, and obtain the polycondensed phosphorus oxychloride intermediate;

[0049] 2. Capping reaction: Control the temperature at 130-140°C and add 230g of phenol dropwise (2.4 moles, the molar ratio of bisphenol A to phenol is 1:3.6), add it in about 3 hours, keep it warm for 2 hours, and recover the phenol under vacuum Temperature is 2~3KPa, temperature is 130~140 ℃, obtain bisphenol A-bis(diphenyl phosphate) crude product;

[0050] 3. Crude product refinement: Alkaline washing of bisphenol (diphenyl phosphate) and water ...

Embodiment 2

[0059] It is basically the same as Example 1, but toluene is used as the solvent instead, and the others remain unchanged, and the yield is 96.8%.

Embodiment 3

[0061] Basically the same as Example 1, the vacuum of phosphorus oxychloride distilled under reduced pressure is 2.8~3KPa, and the others are unchanged, and the yield is 96.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com