Light painting film splicing method

A film and light painting technology, used in printing, plate preparation, etc., can solve the problems of small size and difficult to achieve precision requirements, and achieve the effect of increasing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

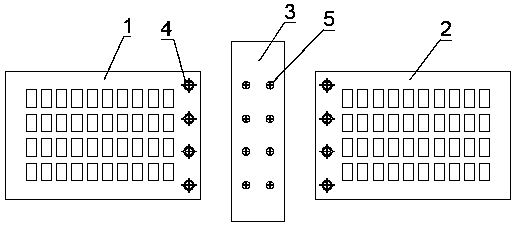

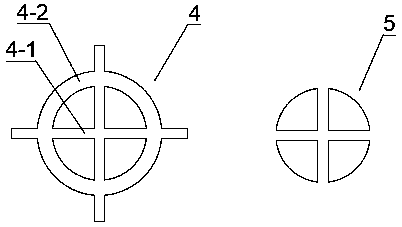

[0014] Such as figure 1 , figure 2 As shown, a kind of photopainting film splicing method described in this embodiment prepares two spliced films, namely No. 1 spliced film 1 and No. 2 spliced film 2, and then prepares a sleeve film 3; The right side of the film 1 is provided with a row of No. 1 positioning patterns 4 at intervals, a row of No. 1 positioning patterns 4 is arranged on the left side of the No. 2 splicing film 2, and a row of No. 2 positioning patterns is respectively arranged on the left and right sides of the sleeve film 3 5. The No. 1 positioning pattern 4 and the No. 2 positioning pattern 5 are mutually coordinated and positioned, and the No. 1 positioning pattern 4 on the No. 1 splicing film 1 and the No. 1 positioning pattern 4 on the No. 2 splicing film 2 are respectively aligned with the After matching the No. 2 positioning pattern 5 on the set film 3, the No. 1 splicing film 1 and the No. 2 splicing film 2 are butted; brush glue on the set film 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com