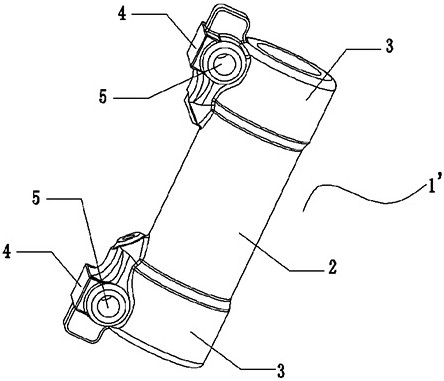

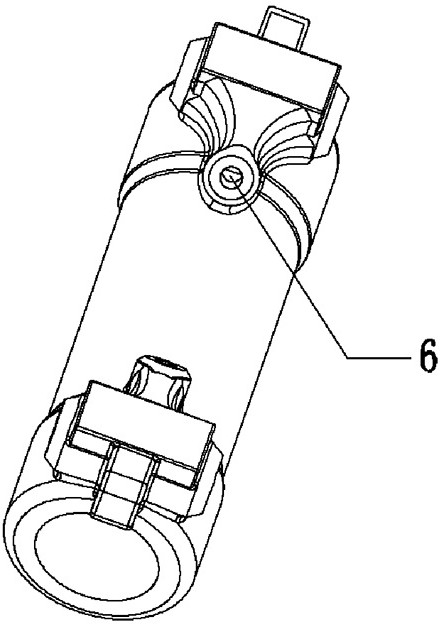

Casting system and casting method for cylinder barrel

A cylinder and casting technology is applied in the field of casting systems for cylinders to achieve the effects of improving machining accuracy, reducing casting defects and accelerating cooling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Weigh 600kg of pig iron, 100kg of scrap steel, and 2.5kg of recarburizer;

[0054] (2) First add 2.5kg recarburizer, then put all the pig iron and steel scrap into the smelting furnace; heat to melt the charge, add 9kg of FeSi75-C ferrosilicon after the charge is melted, add 1.4kg of electrolytic copper, The original molten iron is obtained, and the original molten iron is continued to be heated to 1530 °C; the composition and mass percentage of the obtained original iron liquid are C 3.74%, Si 1.65%, Mn0.12%, P 0.033%, S 0.012%, Cu0. 18%, the rest is iron;

[0055] (3) Carry out spheroidization by the flushing method, add 10kg of nodulizing agent; add inoculant with the flushing method, and inoculate the former molten iron, the addition of the inoculant is 3.5kg, stir evenly, and obtain molten iron; The composition and mass percentage of the molten iron are C3.69%, Si 2.40%, Mn 0.12%, P 0.033%, S 0.0095%, Cu 0.18%, CE (carbon equivalent) 4.5%, and the rest is iron...

Embodiment 2

[0061] (1) Weigh 630kg of pig iron, 70kg of scrap steel, and 2.1kg of recarburizer;

[0062] (2) First add 2.1kg recarburizer, then put all the pig iron and steel scrap into the smelting furnace; heat to melt the charge, add 9.5kg of FeSi75-C ferrosilicon after the charge is melted, and add 1.12kg of electrolytic copper , to obtain the original molten iron, continue to heat the original molten iron to 1520 ° C; the composition and mass percentage of the obtained original iron liquid are C 3.80%, Si 1.67%, Mn0.15%, P 0.035%, S 0.011%, Cu0 .15%, the remainder being iron;

[0063] (3) Carry out spheroidization by the flushing method, add 9.5kg of nodularizing agent; add inoculant with the flushing method, and inoculate the former molten iron, the addition of the inoculant is 3.15kg, stir evenly, and obtain molten iron; The composition and mass percent of this molten iron are C3.72%, Si 2.52%, Mn 0.15%, P 0.035%, S 0.009%, Cu 0.15%, CE (carbon equivalent) 4.57%, and the rest is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com