Folding rotary crossing over frame

A spanning and rotating technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing the workload of construction personnel, separate installation of hard-sealed nets and poles, and many dangerous points, and achieves strong, durable, safe, reliable, and guaranteed. The effect of network closure time requirements and high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

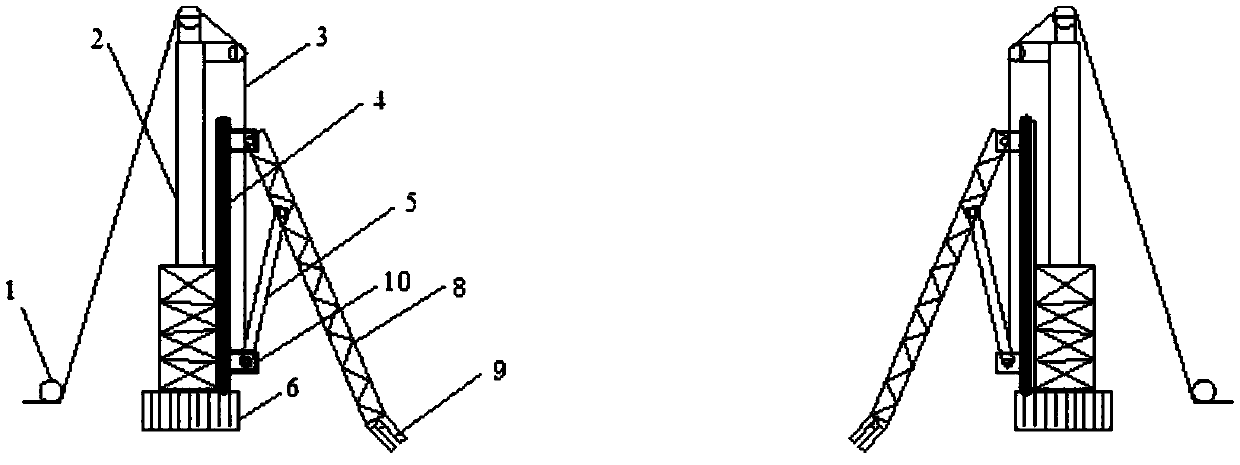

[0025] Such as figure 1 As shown, it is a schematic diagram of the initial installation of the folding and rotating spanning frame provided by the present invention. After adjusting different spanning heights through the lifting platform 2, the power device is used to drive the power rope 3 through the steering pulley 1 to realize the folding strut 5 moving up and down along the slide rail 4. After the folding arm 8 is opened, the rotation of the rotating platform 6 quickly realizes folding on both sides Arm 8 seals the net butt.

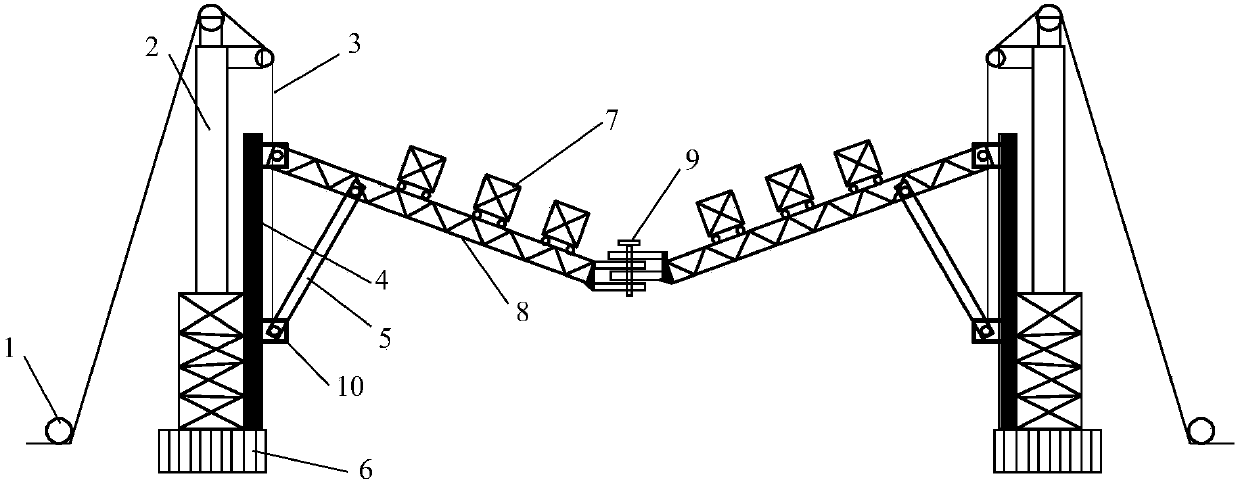

[0026] Such as figure 2 As mentioned above, it is a schematic diagram of the lapped and rotated spanning frame provided by the present invention. The spanning frame includes a rotating mechanism, a lifting mechanism and an executing mechanism arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com