Environment-friendly high rebound flame retardant composite fabric

A flame retardant composite and composite fabric technology, applied in the field of textile fabrics, can solve the problems of poor tensile properties, easy looping and wrinkling of fabrics, etc., and achieve good environmental protection flame retardant performance, good elastic memory function, good elasticity The effect of recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

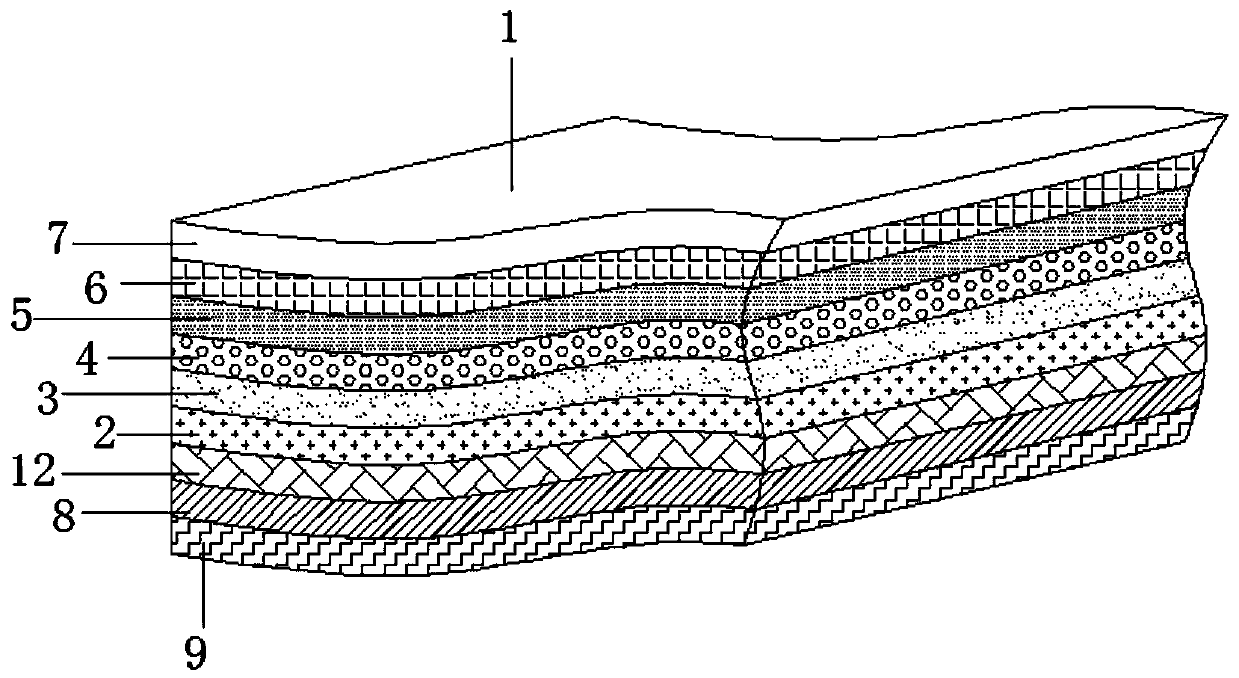

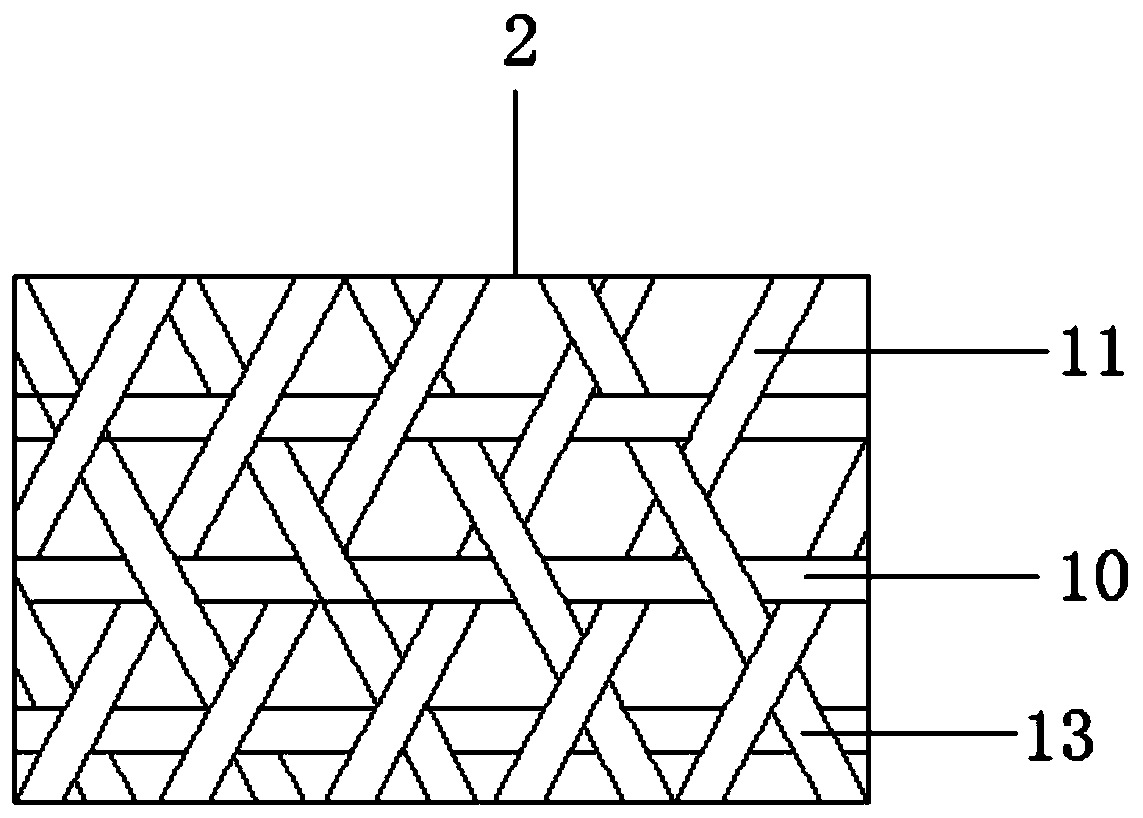

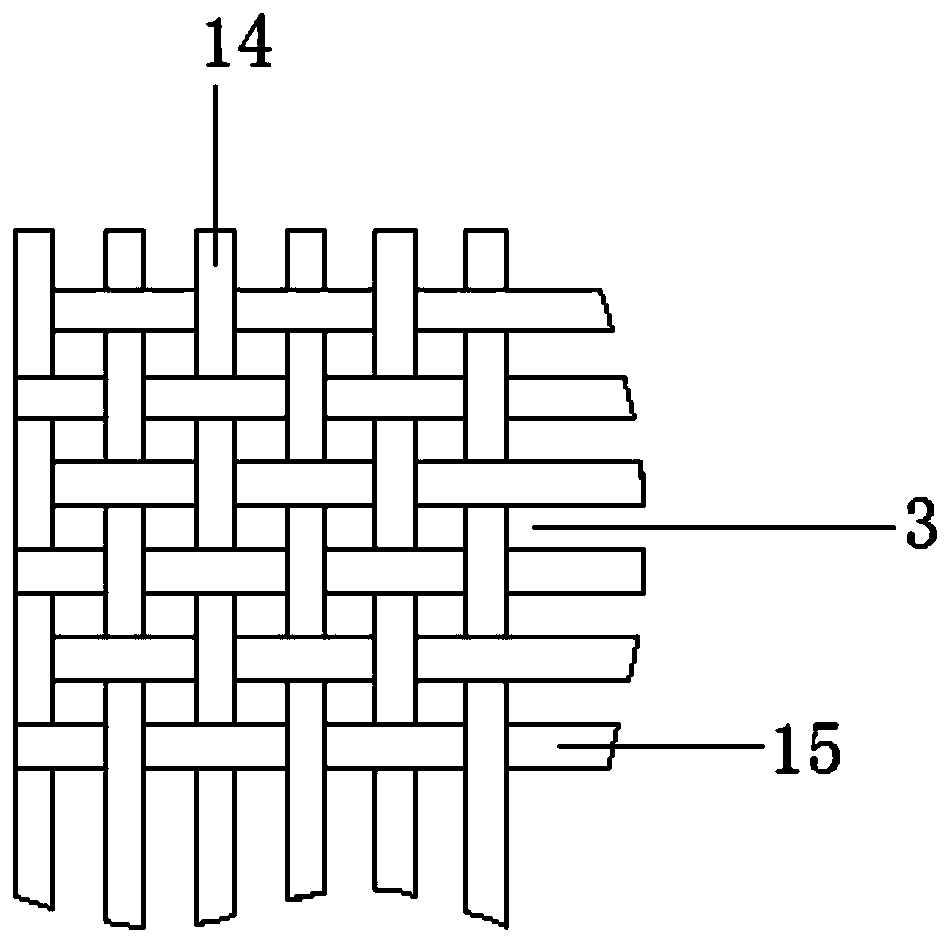

[0020] like Figure 1-4 As shown, an environment-friendly high-resilience flame-retardant composite fabric includes a composite fabric body 1, and the composite fabric body 1 is composed of an elastic layer 2, a base fabric layer 3, a breathable layer 4, an antistatic layer 5, and a flame-retardant layer 6. , insulation layer 7, protective layer 8, cotton cloth layer 9, nano-silver antibacterial layer 12, the elastic layer 2 is arranged on the bottom of the base cloth layer 3, the air-permeable layer 4 is arranged on the top of the base cloth layer 3, and the antistatic Layer 5 is arranged on the top of the air-permeable layer 4, the flame retardant layer 6 is arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com