Ejection mechanism for inner side of sliding block

A technology of ejector mechanism and slider, which is applied in the field of injection mold design, can solve problems such as mold sticking, increase production cost, damage product appearance, etc., and achieve the effect of ensuring product appearance and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

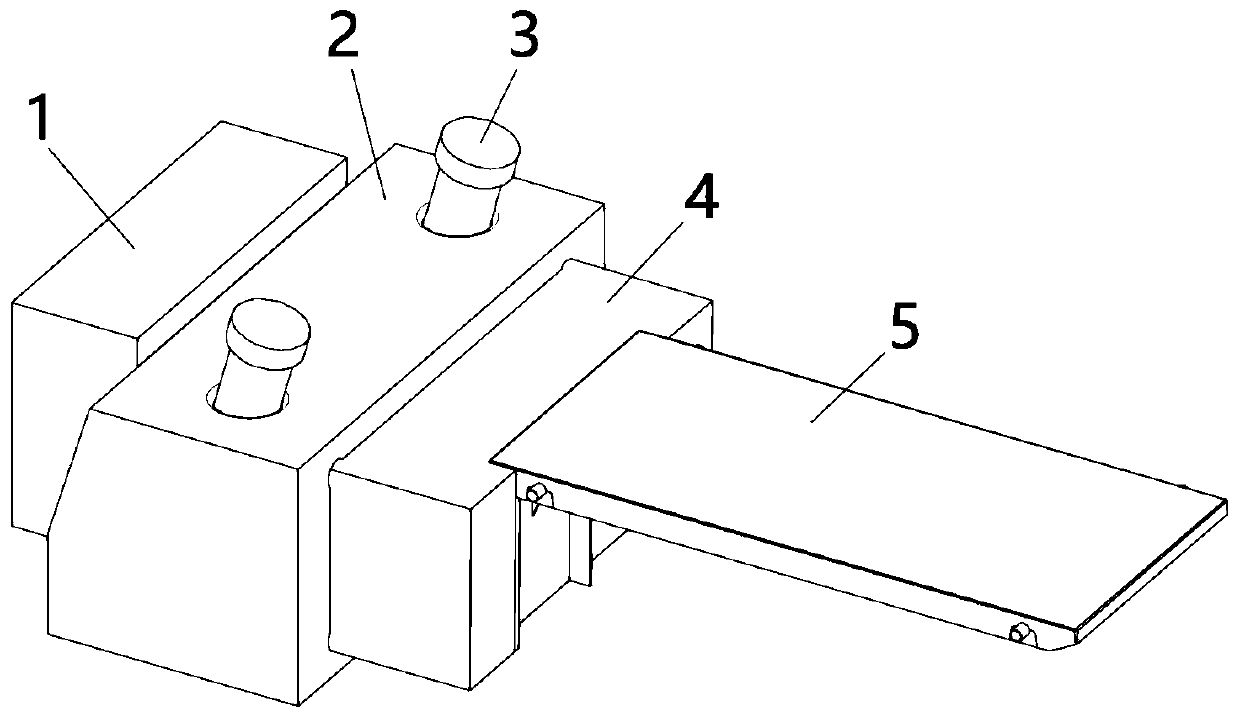

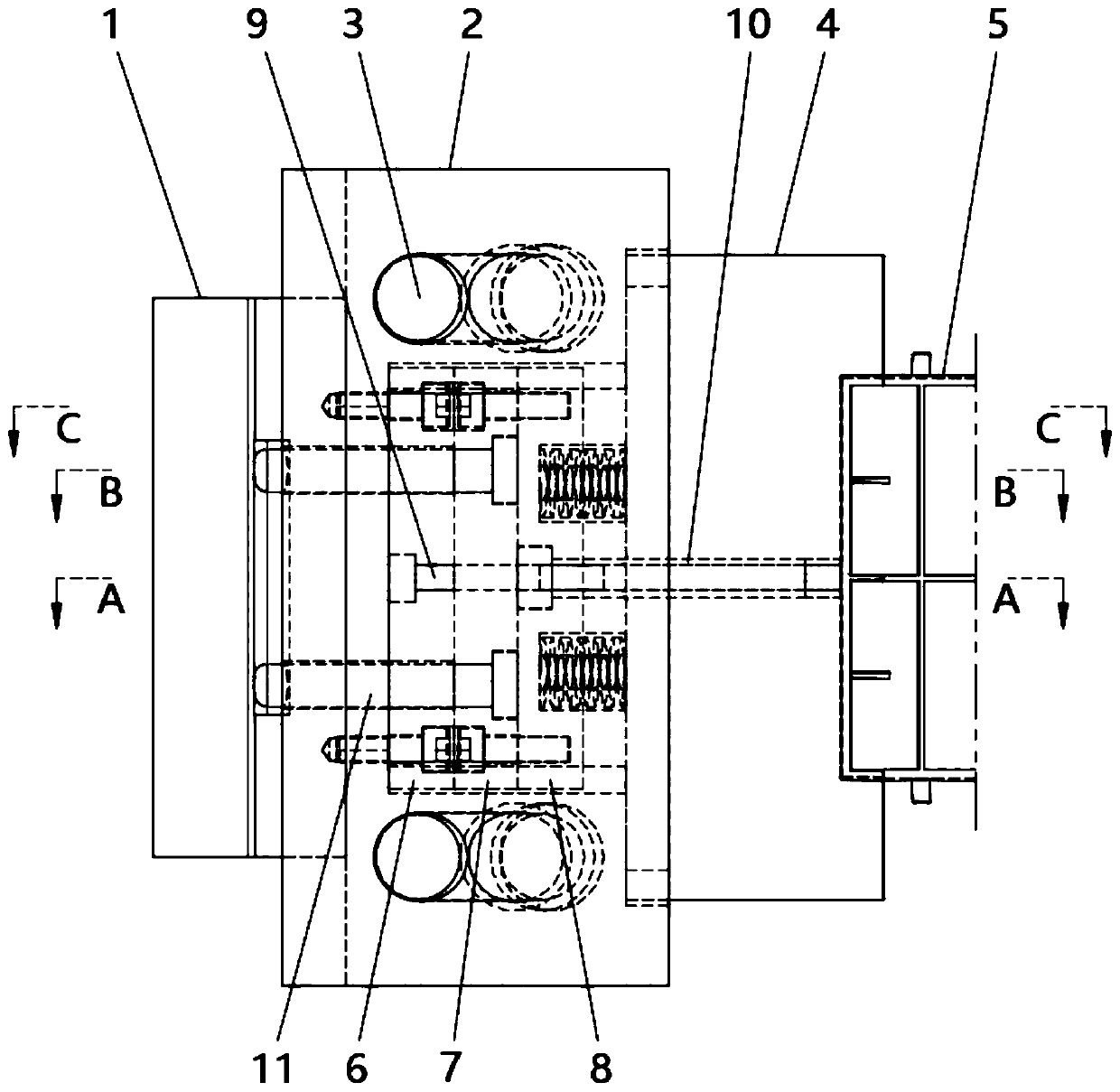

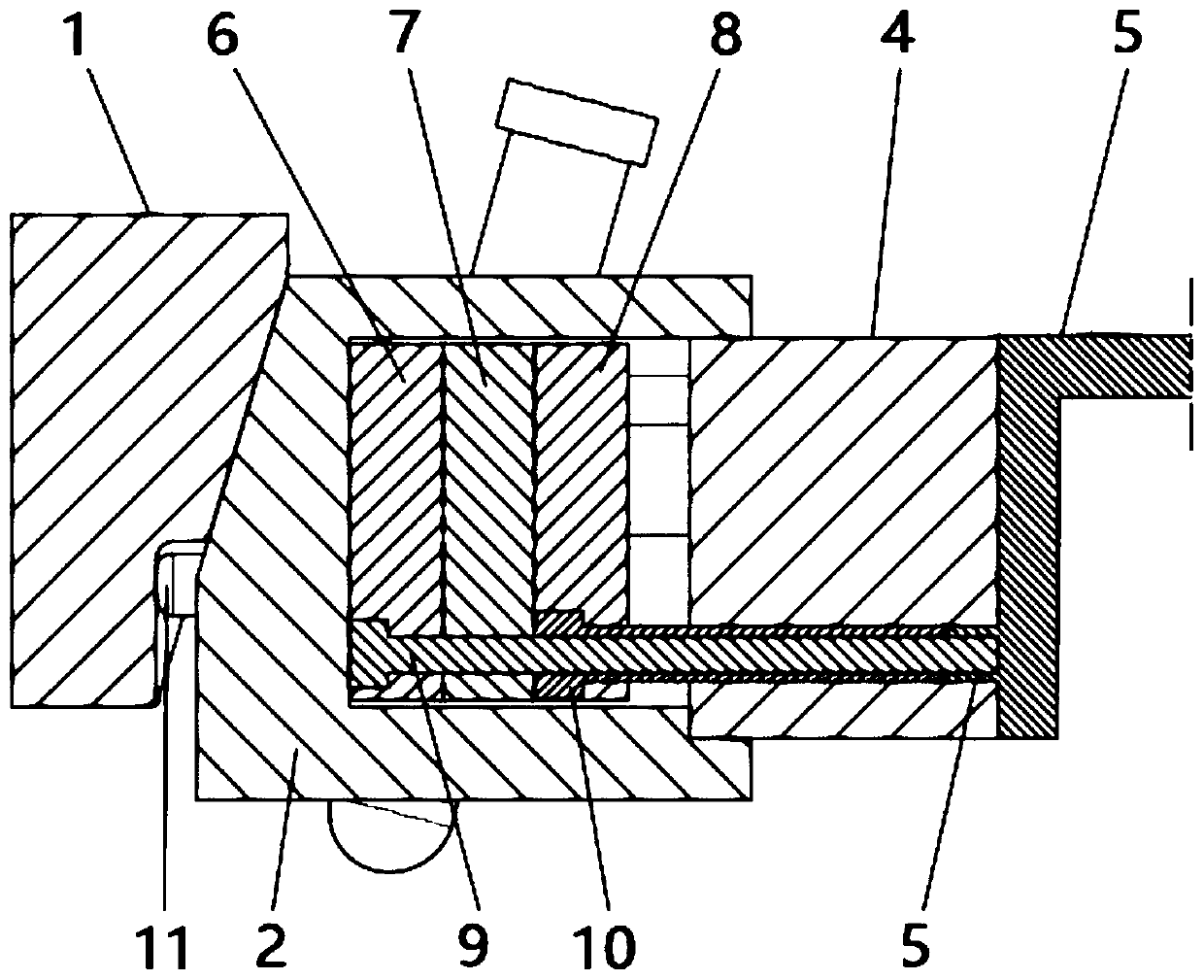

[0017] like Figure 1 to Figure 5 As shown, this embodiment provides a mechanism for ejecting the inner side of the slider, which includes a shovel base 1, a slider seat 2, an oblique guide post 3, and a slider 4; 2 is used to move the slider seat left and right; the upper half of the left side of the slider seat 2 is provided with a first slope, and the right side is fixed with the slider 4; the right side of the shovel base 1 is provided with a The second inclined surface matched with the first inclined surface; the middle position of the lower part of the second inclined surface is provided with a flat position 12; The left fixed block 7, the right fixed block 8 of the tube; the fixed block 6 of the tube needle is fixed with the slider seat 2, and the tube pin 9 which is worn to the right is jointly fixed; the left fixed block 7 of the tube is connected with the The right fixing block 8 of the cylinder is fixed, and is jointly fixed with the cylinder 10 which is penetrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com