Composite water pipe

A technology of water pipes and support pipes, applied in the field of pipelines, to achieve the effect of effectively resisting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

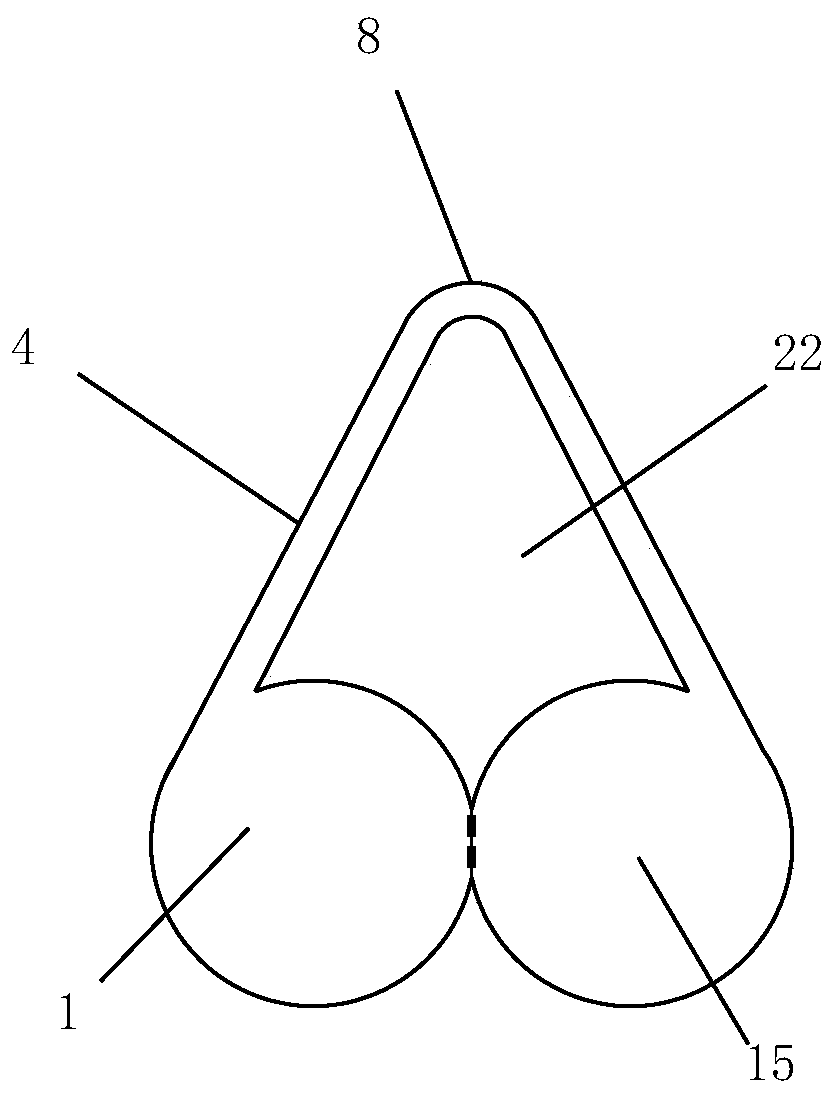

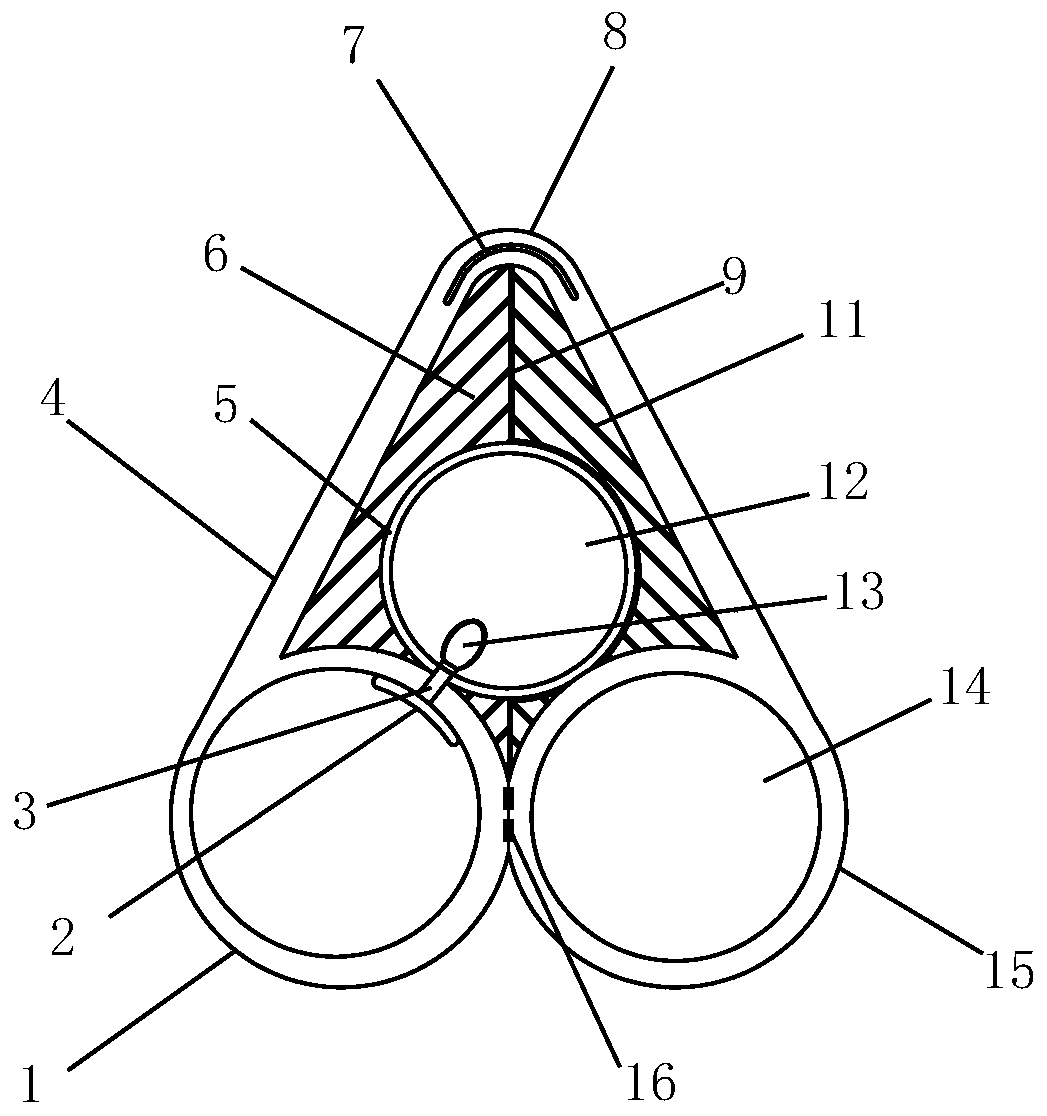

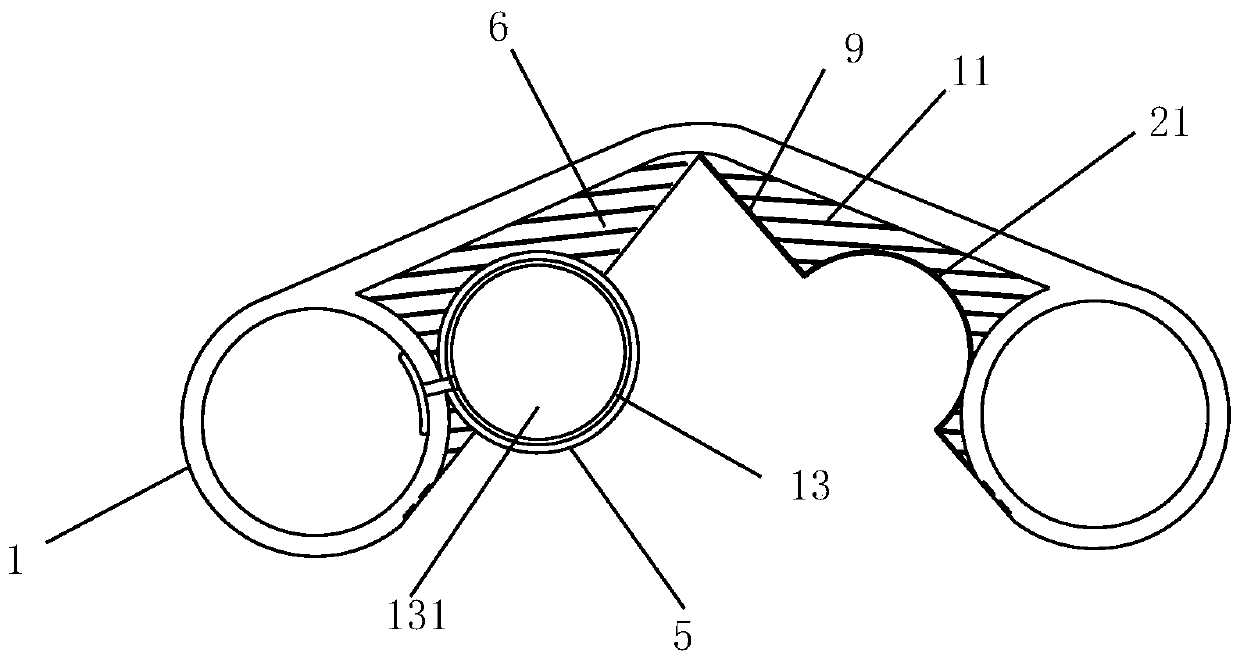

[0014] Such as figure 1 and figure 2 As shown, the composite water pipe includes two flexible support pipes arranged side by side, the two support pipes are in contact with each other, the bottom of the support pipes is in contact with the ground, and the two flexible support pipes include the first support pipe 1 and the second support pipe 15. A connecting piece 4 is arranged obliquely on the outer surface of the support tube, and the adjacent connecting piece 4 extends upwardly and converges at the top, forming an arc-shaped connecting part 8 at the junction;

[0015] An elastic metal sheet 7 is embedded in the arc-shaped connecting part 8, and a drainage channel 22 is formed between two flexible support pipes and the two connecting pieces. The end is sealed by a spliced sealing part, and the input pipe 5 extends into the drainage channel 22 through the sealing part. An air storage chamber 14 is arranged in the first support pipe 1 and the second support pipe 15, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com