Control system for remotely controlling operation of industrial robot

A technology for industrial robots and control systems, applied in control/adjustment systems, program-controlled manipulators, two-dimensional position/channel control, etc., can solve problems such as inability to remotely control industrial robots, operator personal safety and physical and mental health hazards, etc. Achieve the effect of reducing professional skill level requirements, facilitating operation activities and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

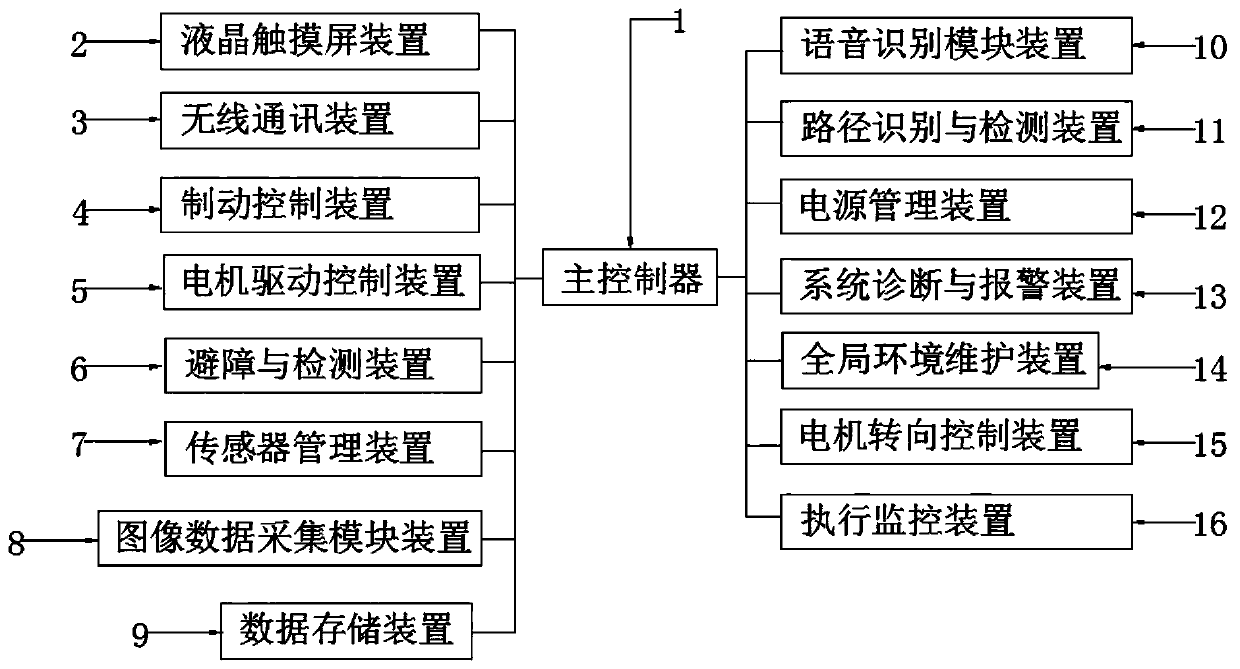

[0026] Embodiment one, such as figure 1 As shown, a control system for remotely controlling the operation of an industrial robot according to an embodiment of the present invention includes a main controller 1, a liquid crystal touch screen device 2, a wireless communication device 3, a brake control device 4, a motor drive control device 5, an obstacle avoidance and detection device 6, sensor management device 7, image data acquisition module device 8, data storage device 9, voice recognition module device 10, path recognition and detection device 11, power management device 12, system diagnosis and alarm device 13, global environment maintenance device 14, motor steering control device 15 and execution monitoring device 16, wherein the output terminals of the main controller 1 are respectively connected to the liquid crystal touch screen device 2, the wireless communication device 3, the braking control device 4, The motor drive control device 5, the obstacle avoidance and d...

Embodiment 2

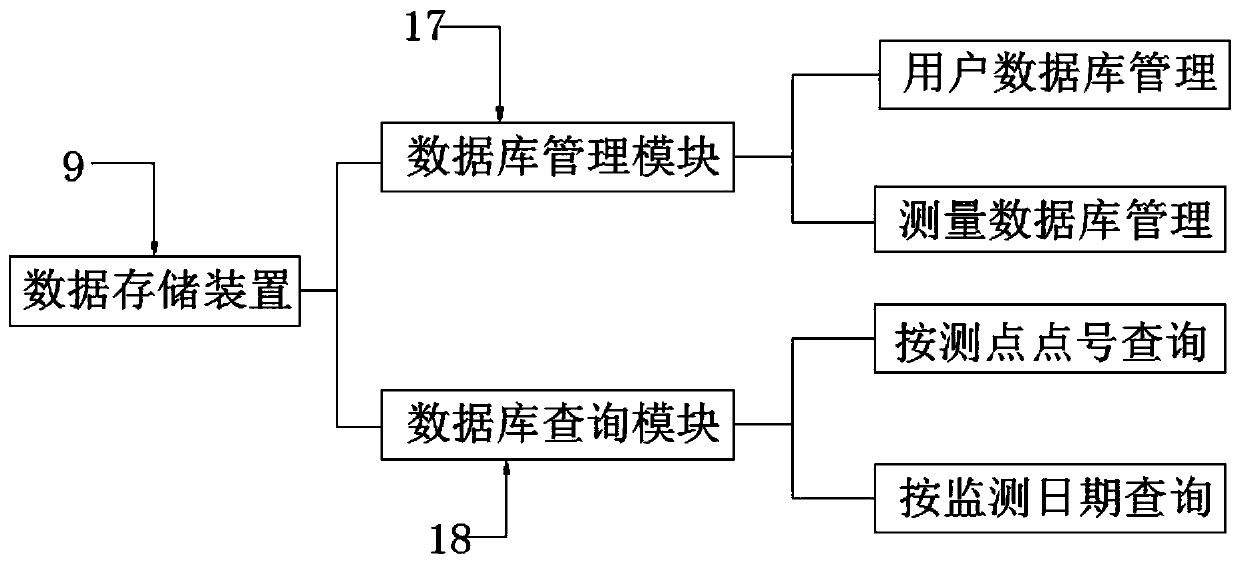

[0027] Embodiment two, such as image 3 As shown, the data storage device 9 includes a database management module 17 and a database query module 18, the database management module 17 includes a user database management module and a measurement database management module, and the database query module 18 includes a query module by measuring point number and query modules by monitoring date.

Embodiment 3

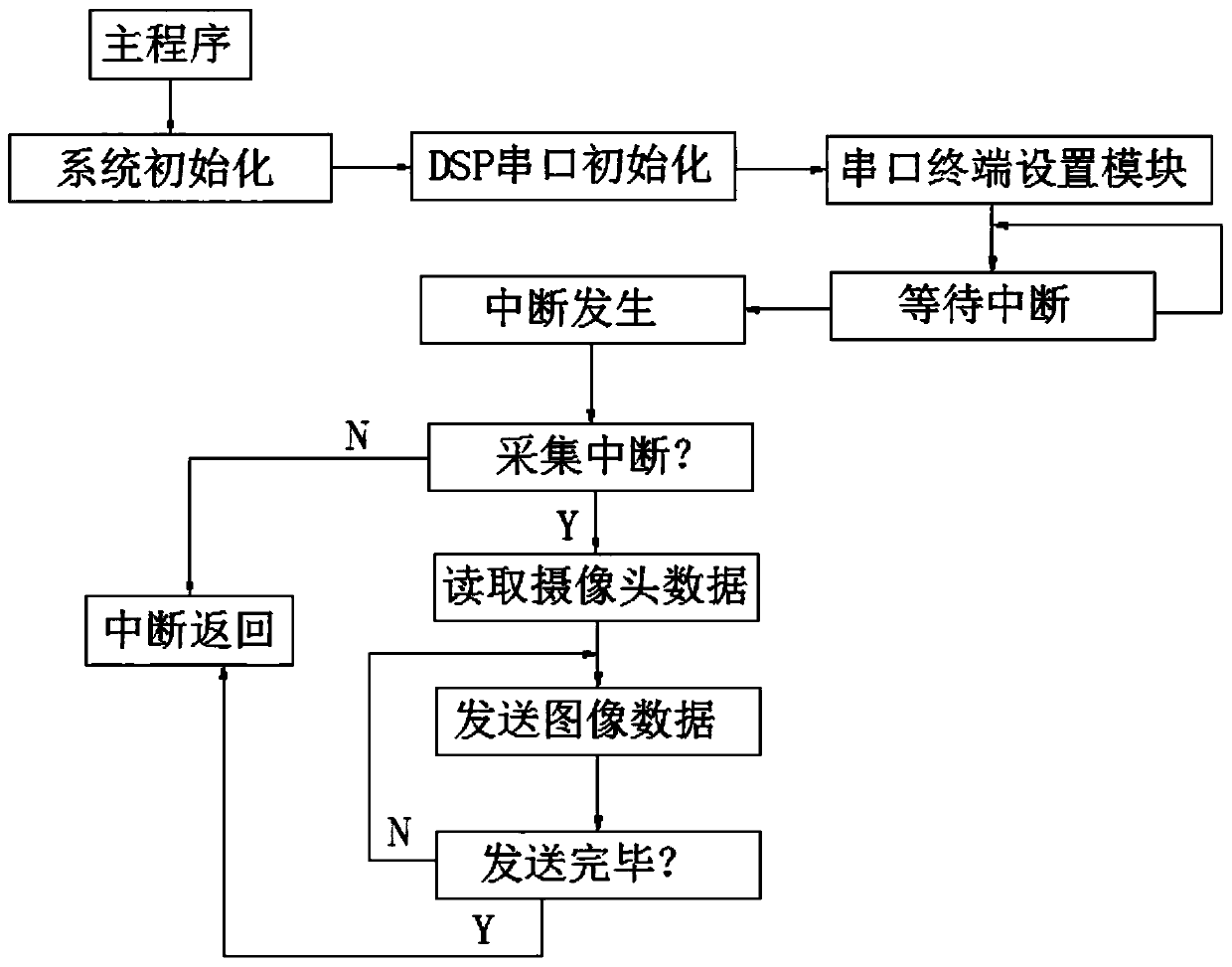

[0028] Embodiment three, such as Figure 4 As shown, the specific steps of the method for collecting information by the robot include the following:

[0029] S101: Initialize the system;

[0030] S102: Collect information to obtain an information collection module;

[0031] S103: Perform information preprocessing through the collected information;

[0032] S104: Send the preprocessed information to the background;

[0033] S105: The information received by the background will execute the instruction if the instruction is received within the specified time range, and return to the information collection module to re-collect information if the instruction is not received within the specified time range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com