Cladding pumping single-mode terahertz fiber laser

A fiber laser, terahertz technology, applied in the field of terahertz lasers, can solve the problems affecting beam quality, loss, and bulky, and achieve the effects of improving beam quality, improving utilization, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

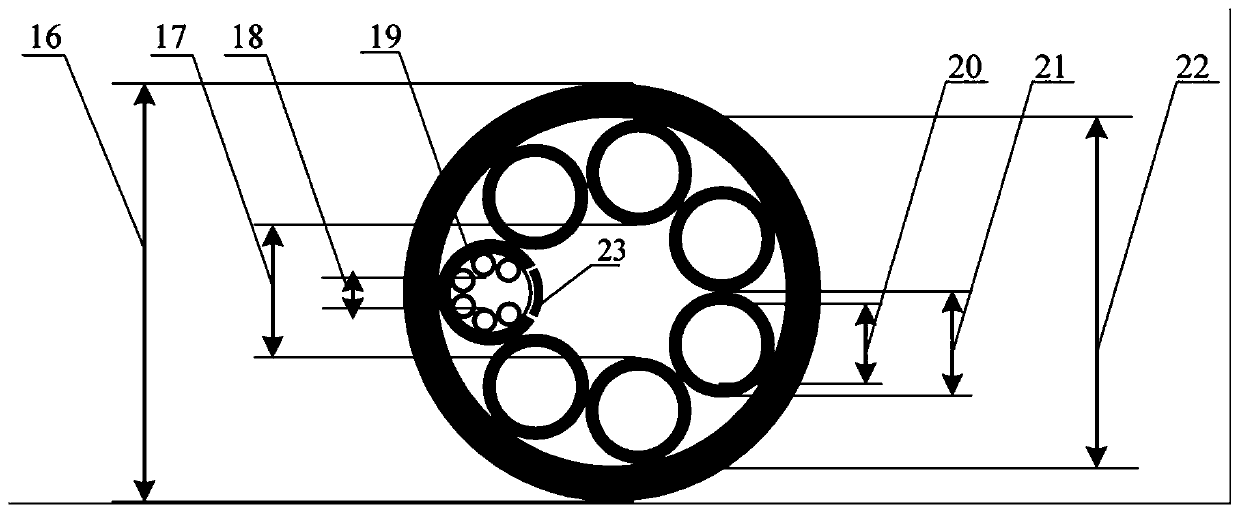

[0027] The cladding-pumped single-mode terahertz fiber laser of this embodiment is as figure 1 As shown, the continuously tunable carbon dioxide laser 1 can output pump laser light with a central wavelength of 9.69 μm. Firstly, use ZnSe convex lens 2 and ZnSe concave lens 3 to control the beam of the pump laser to reduce the spot size of the pump laser so that it can be better coupled with the fiber adapter I8 to enter the mid-infrared hollow core In the middle hollow core region of the optical fiber 4 , the pump light can be transmitted with low loss due to the anti-resonance effect in the mid-infrared hollow core optical fiber 4 . Press the fiber optic adapter II9, fiber optic ada...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com