Method and device for testing fault of internal motor of compressor

A technology for internal faults of compressors, which is applied in the field of inspection of internal motor faults of compressors, and can solve problems such as high testing costs, insufficient effectiveness, and low testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

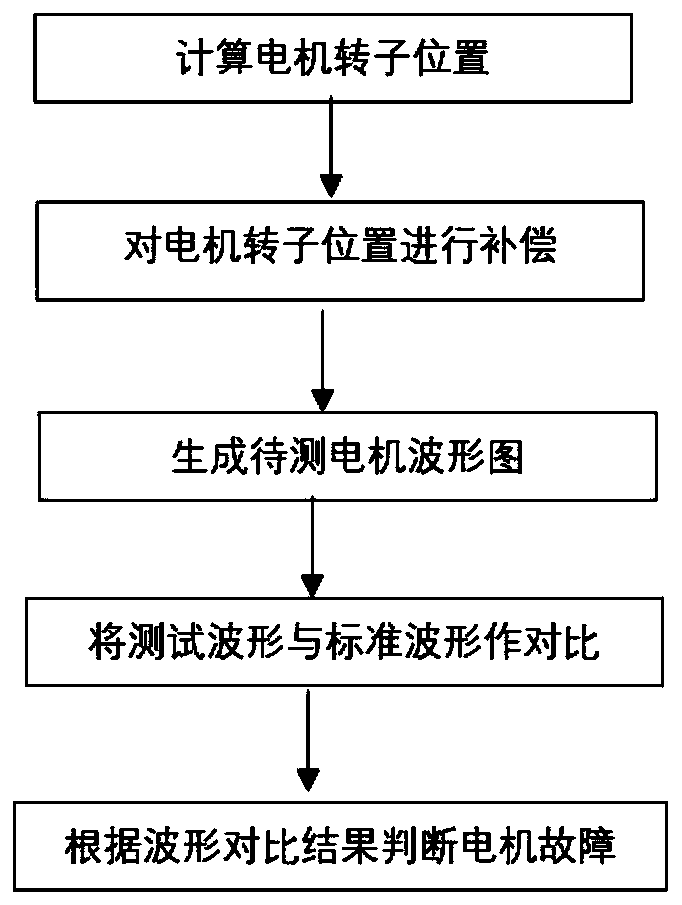

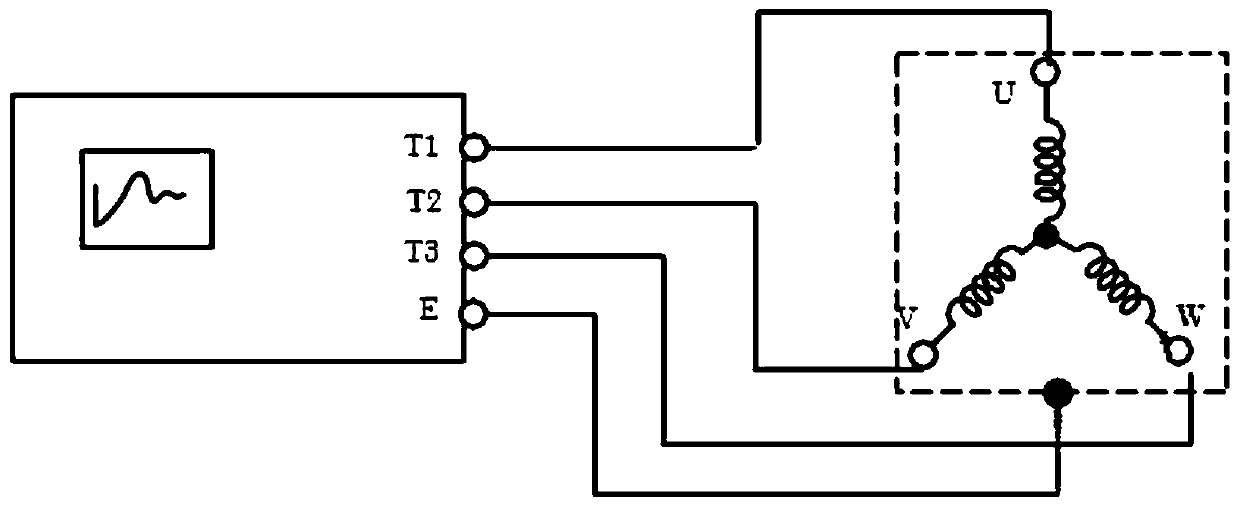

[0042] combine Figure 1-Figure 12 , the present embodiment discloses a method and equipment for checking internal motor faults of a compressor, wherein the equipment to be used mainly includes a coil pulse interlayer tester, connecting wires and a compressor to be tested.

[0043] Such as figure 2 As shown, the coil pulse interlayer tester is respectively connected to the three phases of the motor coil through the high voltage test line (the interface is T1, T2 and T3), and connected to the iron core of the motor through the interface E.

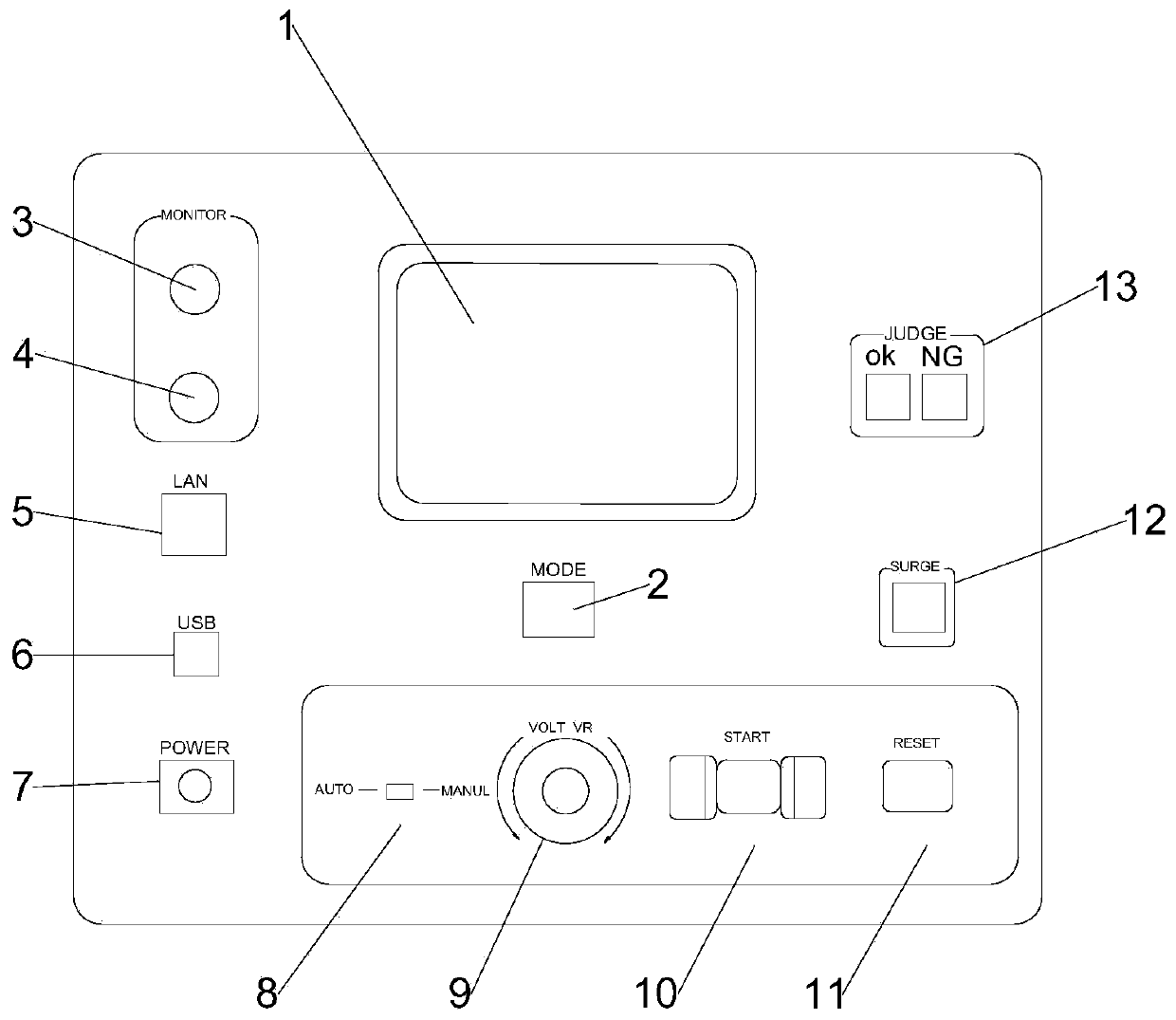

[0044] Such as image 3 As shown, the display 1 on the front panel of the coil pulse interlayer tester is a liquid crystal display touch screen, which displays the test waveform and the standard waveform and puts them at the same starting point for comparison. The standard waveform is blue, and the test waveform is red. If the test waveform is the same as the standard waveform, the judgment result is a good product, and the display 1 dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com