A vortex tube refrigeration device with sleeve-type cold flow outlet

A refrigeration device, a casing-type technology, which is applied in the refrigeration field of engineering thermophysics, can solve the problem that low-temperature fluid cannot be output and used alone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

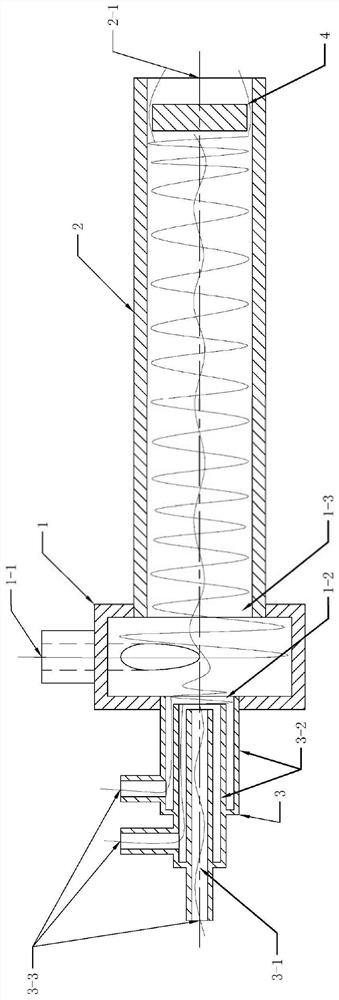

[0017] Such as figure 1 As shown, a vortex tube refrigerating device with a sleeve-type cold flow outlet includes a vortex chamber 1, a hot end pipe 2, and a sleeve-type cold end pipe 3; The end pipe 3 and the hot end pipe 2 are connected; the sleeve type cold end pipe 3 is a mutual coaxial structure composed of a central pipe 3-1 and at least one layer of outer casing 3-2 which are all communicated with the vortex chamber 1. Rotary channel.

[0018] Each flow channel of the central pipe 3-1 and the flow channel of the rotary body is connected to different cold fluid outlets 3-3 that can individually adjust their respective flow rates. The outlets flow out simultaneously, and under normal operating conditions, the several streams of cold fluid are at different temperatures.

[0019] The vortex chamber 1 has a tangential fluid inlet 1 - 1 through which high-pressure fluid flows in; the fluid inlet 1 - 1 of the vortex chamber 1 makes the fluid form a vortex flow in the vortex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com