Telescopic simple tail of scraper conveyer and scraper conveyer

A scraper conveyor, simple technology, applied in the direction of conveyor, transportation and packaging, can solve problems such as difficulty in meeting the requirements of undercover and cut-through bottom plate of the shearer, large overall size, wear of the middle plate, etc. The state is optimized and perfect, the height of the tail is reduced, and the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Carry out the specific embodiment of the present invention in detail below in conjunction with accompanying drawing:

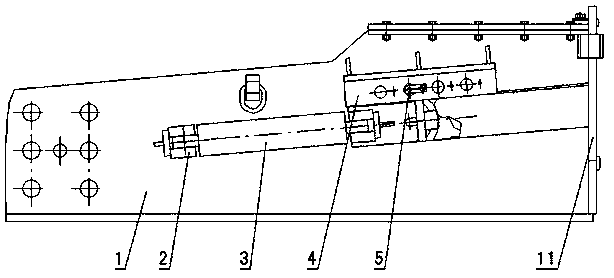

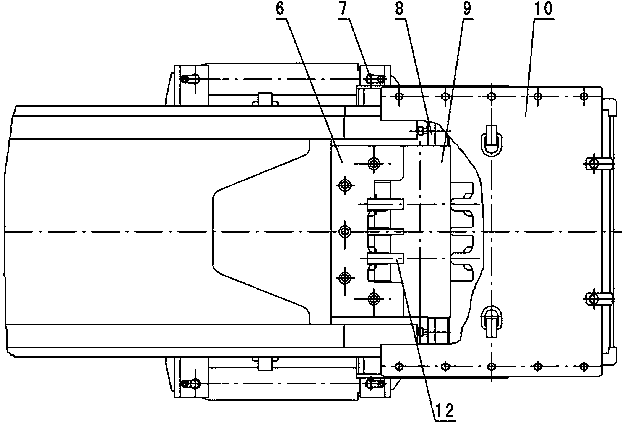

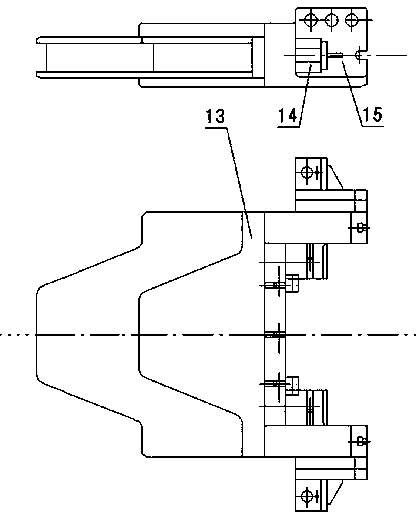

[0023] Such as figure 1 , 2 , 3 and 4, the retractable simple tail of a scraper conveyor of the present invention includes a tail frame 1 and a slide frame 13 built in the tail frame 1 . There are slideways on the slope sections of the side plates on both sides of the tailstock 1, and a positioning plate 4 is arranged above the slideway, and four positioning pin holes with a spacing of 150 mm are evenly arranged on the positioning plate 4. Welded as one. Simultaneously, both sides of the tail frame 1 are provided with connecting ears 2, and the connecting ears 2 and the tail frame 1 are welded as one. There are sliders 15 arranged on both sides of the slider 13, and three positioning pin holes with a spacing of 100 mm are evenly arranged on the slider 15. The slider 15 and the slider 13 are welded into one body, and the two sides of the slider 13 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com