Mounting and adjusting structure for dust collector

A technology for installation adjustment and dust collector, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problem that multiple filter cartridges cannot be installed together at the same time, the stability of pipeline connection is not high, and the installation of dust filter cartridges is inconvenient, etc. problems, to achieve the effect of high overall applicability, good installation stability, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

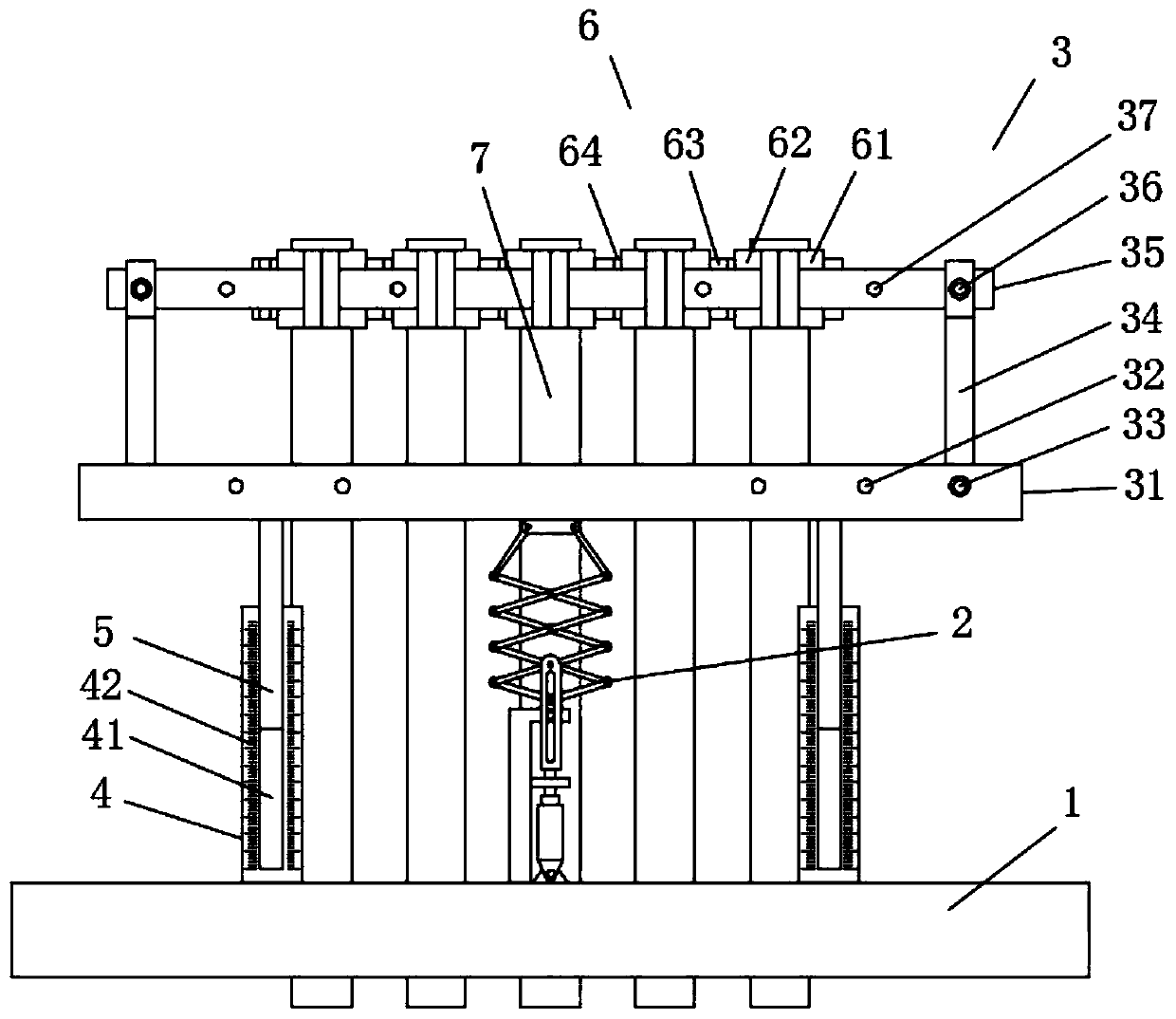

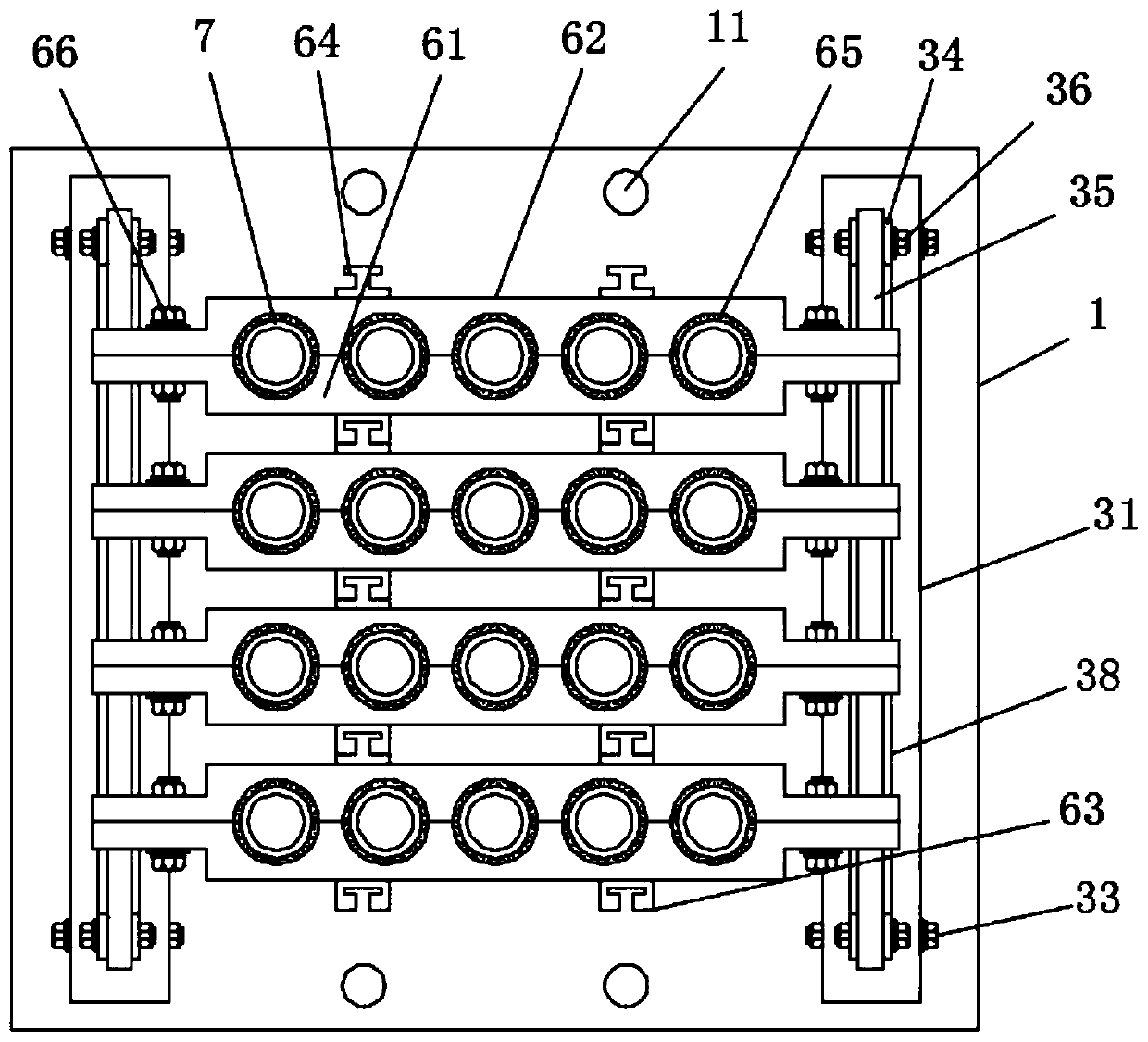

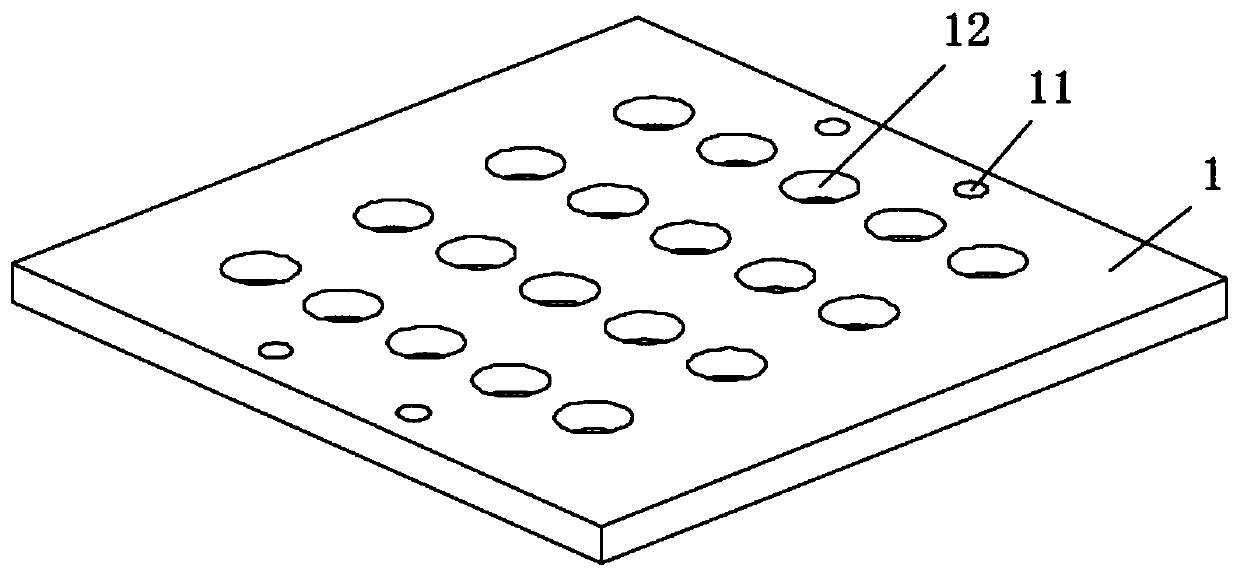

[0021] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a dust collector installation and adjustment structure, including a mounting seat 1, a lifting mechanism 2, an adjusting mechanism 3, a clamping mechanism 6 and a dust removal filter cartridge 7, the upper surface of the mounting seat 1 A pair of fixing holes 11 are provided inside both ends, and a plurality of perforations 12 are arranged on the upper surface of the mounting base 1 and between the two pairs of fixing holes 11, and the upper surface of the mounting base 1 is adjacent to the two pairs of fixing holes 11. Both sides are vertically fixedly connected with a pair of concave brackets 4, the interior of the opposite side of the two pairs of concave brackets 4 is provided with a No. 3 chute 41, and each No. 3 chute 41 is slidably connected with a lifting plate. 5. An adjusting mechanism 3 is provided at the top of each pair of the lifting plates 5, and the adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com