Method for realizing accurate welding between pipeline and flanges

A welding method and flange technology, which is applied in the field of precise welding of pipes and flanges, can solve the problems of inability to maintain concentric axes between flanges and pipes, potential safety hazards, leaking of pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

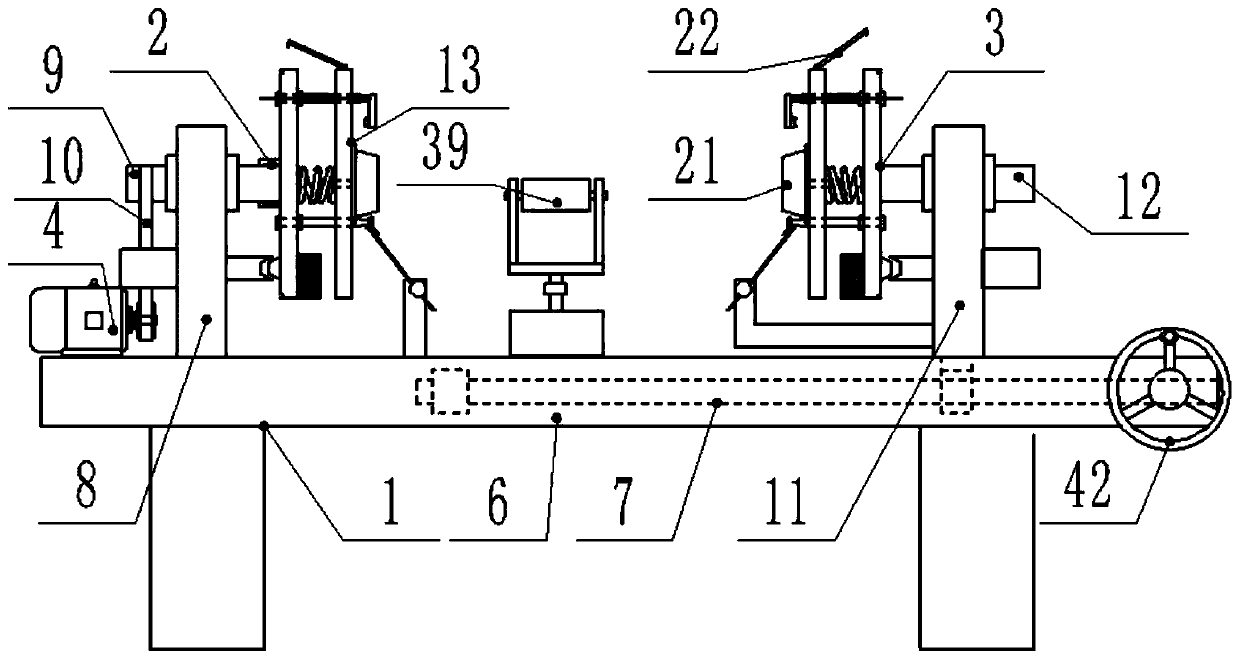

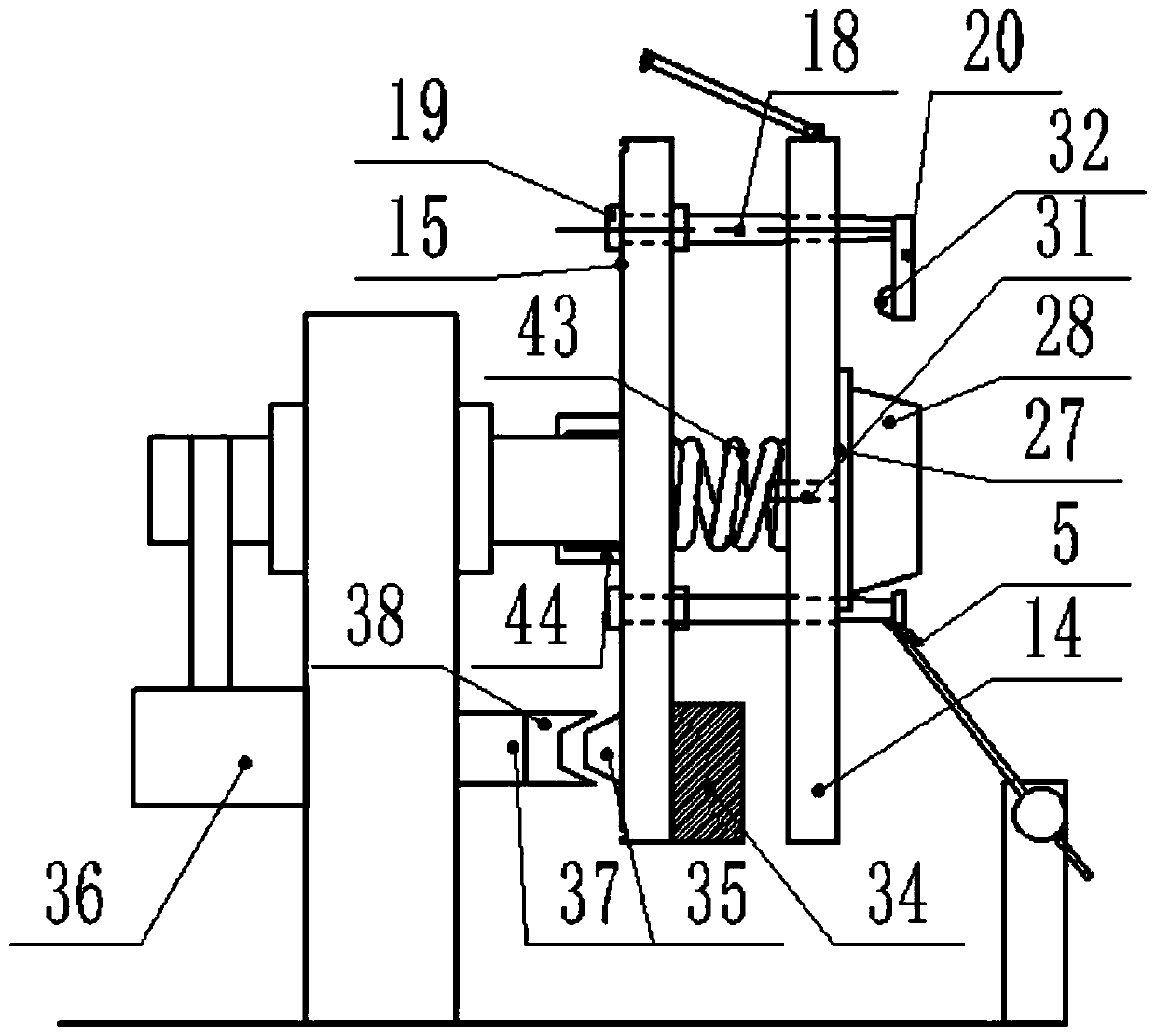

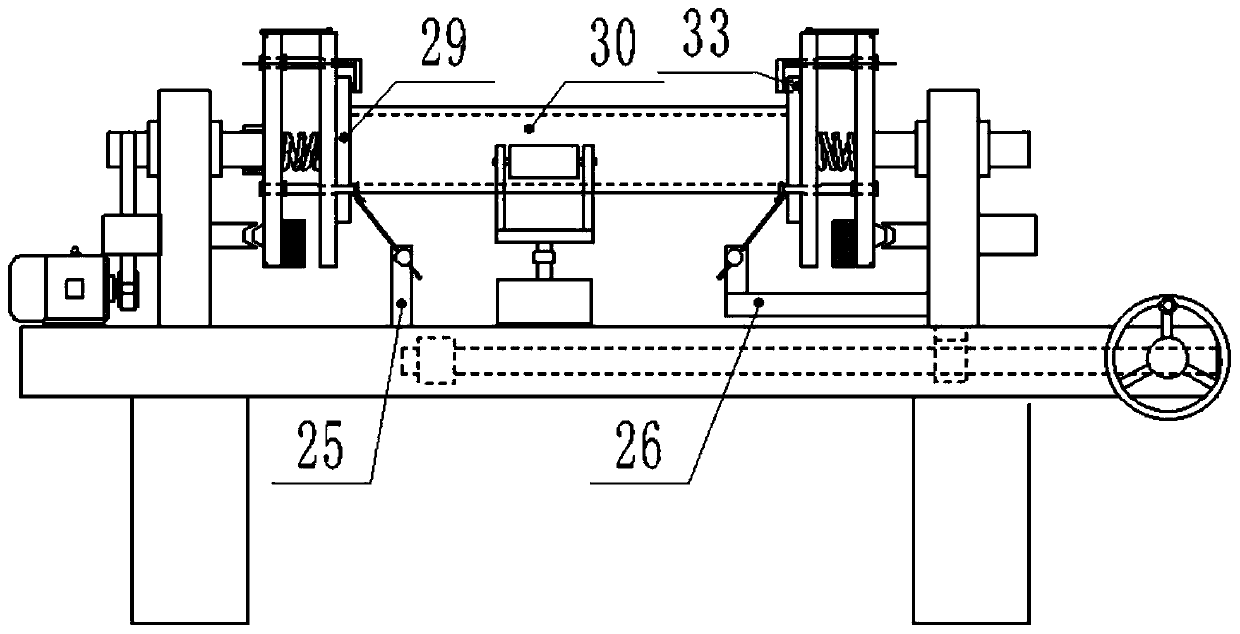

[0048] like Figure 1-9 As shown, the present invention realizes a method for precise welding of pipes and flanges, which is characterized in that it comprises steps:

[0049] Above the welding support frame 1 is a welding table 6, and a drive screw 7 is arranged horizontally inside the right side of the welding table 6. The left flange clamp 2 includes a left welding stand 8, and the left welding stand 8 is fixedly arranged. On the left side of the welding table 6, a left welding rotating shaft 9 is horizontally arranged on the left welding stand 8, and the outer end of the left welding rotating shaft 9 is connected with the drive motor 4 arranged on the welding table 6 through a belt 10. The right method The blue clamp 3 includes a right welding stand 11, which is slidably installed on the welding table 6, and the lower end of the right welding stand 11 is screwed with the transmission screw 7, and the right welding stand is controlled by rotating the transmission screw 7 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com