Lightning protection and grounding construction method for sustainable maintenance without secondary trenching

A lightning protection grounding and construction method technology, which is applied in the direction of excavation, connection, and connection of contact materials, etc., can solve the problem of not being able to refill electrolyte or paste rent-reducing agent twice, failing to meet the grounding resistance requirements of communication systems, and level Grounding body products do not have maintainability and other issues, so as to reduce the amount of construction work and maintenance, improve maintenance efficiency, and shorten the penetration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the examples.

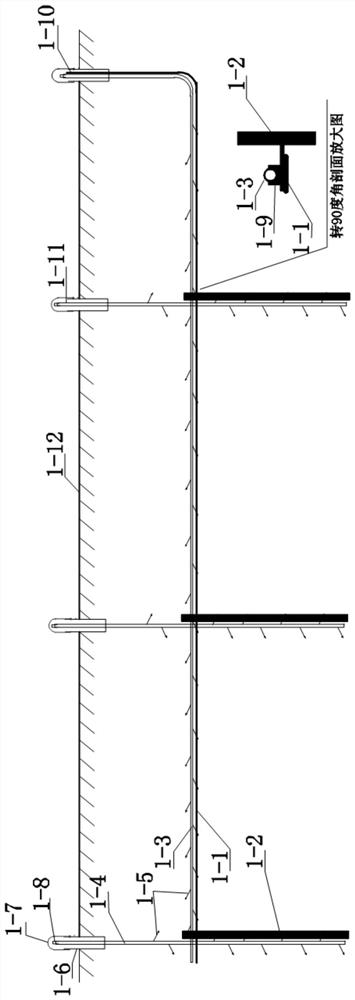

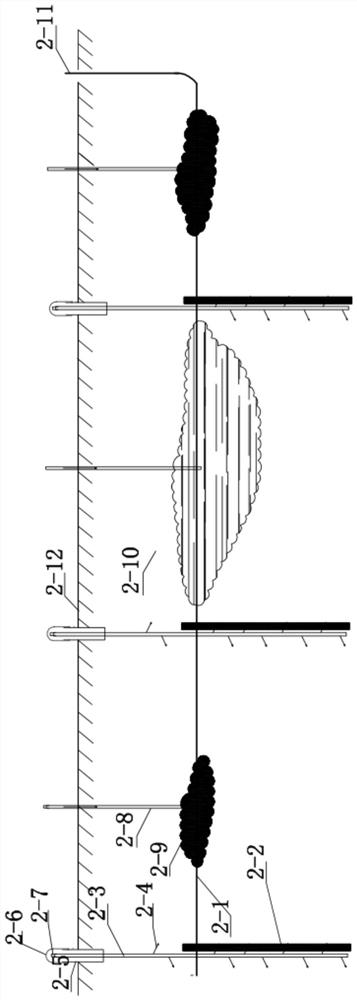

[0062] A lightning protection and grounding construction method for sustainable maintenance without secondary trenching. The construction method includes a construction method for a new lightning protection grounding field and a maintenance construction method for a lightning protection grounding field that has been built using traditional methods. The newly built lightning protection grounding field The construction method of the ground field includes the construction design of the lightning protection grounding horizontal grounding body and the construction design of the lightning protection grounding vertical grounding body. Maintain construction design.

[0063] The soil permeability formula clarifies that the permeability is directly proportional to the magnitude of the external force, has a quadratic parabolic relationship with the radius of the circular pipe, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com