Automatic control system and method based on Beidou positioning and ploughing depth measurement

An automatic control system and Beidou positioning technology, applied in the direction of control/adjustment system, non-electric variable control, control using feedback, etc., can solve the problems of manpower consumption, unevenness, and inaccurate adjustment, so as to achieve convenient parameter adjustment, Reduce the effect of manual adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

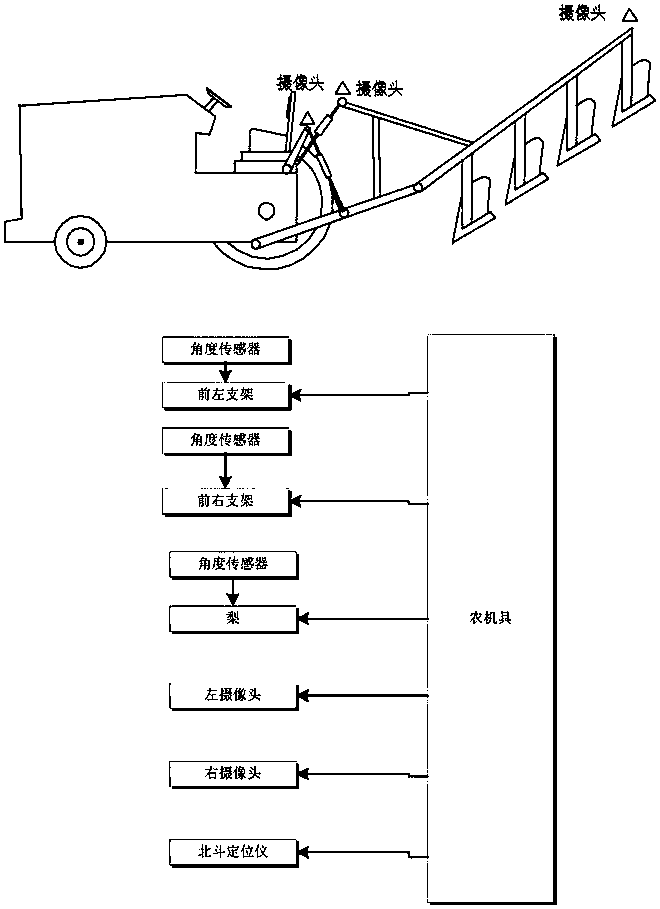

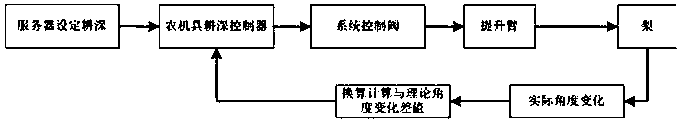

[0014] The present invention provides a set of control system that can be controlled from the cloud to automatically adjust the agricultural implements. The control system is based on Beidou positioning and tillage depth measurement technology, combined with cloud computing, through data collection of real-time position information and tillage depth status of agricultural machinery and tools, setting the target value of tillage depth on the cloud server, and the agricultural implements receive the command of the target value of tillage depth Finally, the relevant mechanical parts are automatically controlled to perform closed-loop control, and the control ensures that the plowing depth is reached. In order to better understand the technical solution, the present invention will be described in detail below in conjunction with the accompanying drawings.

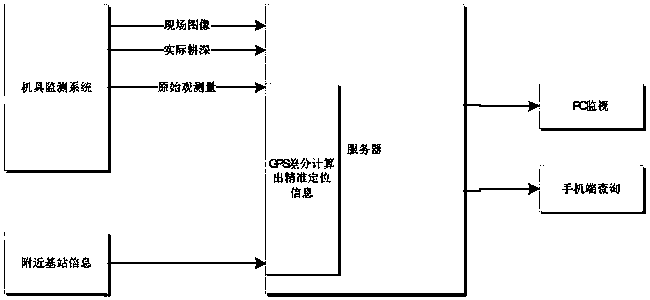

[0015] figure 1 It is the overall system frame diagram of the technical solution. An automatic control system based on Beid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com