Mining underground large part X type truck loader

A technology of large parts and loader, applied in conveyors, loading/unloading, mechanical conveyors, etc., can solve the problem of not being able to meet the requirements of large-tonnage hydraulic support loading, delaying the total time of working face retraction, restricting the mine Production continuation and other issues, to achieve the effect of saving labor costs, shortening loading time, and reducing operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

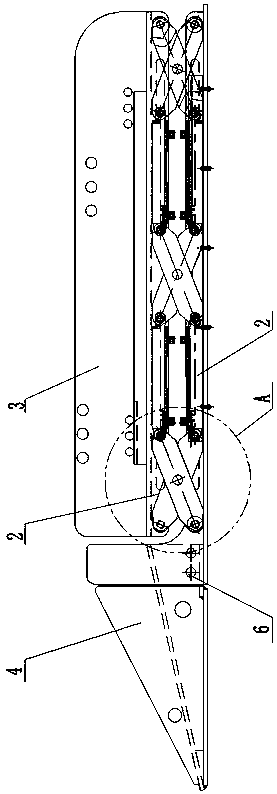

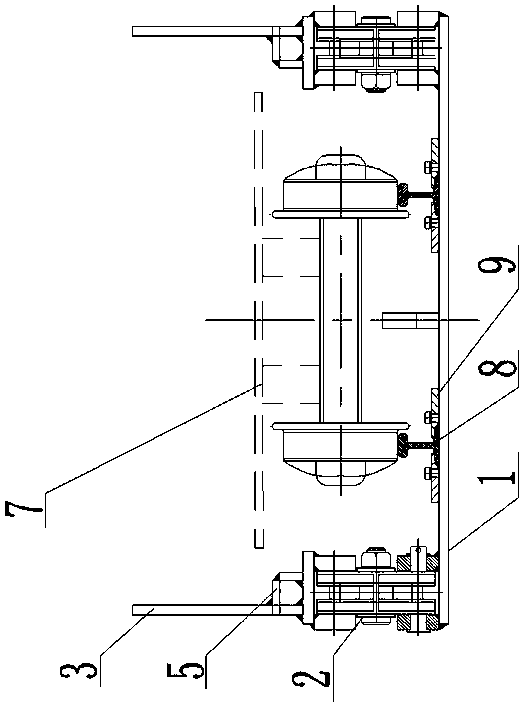

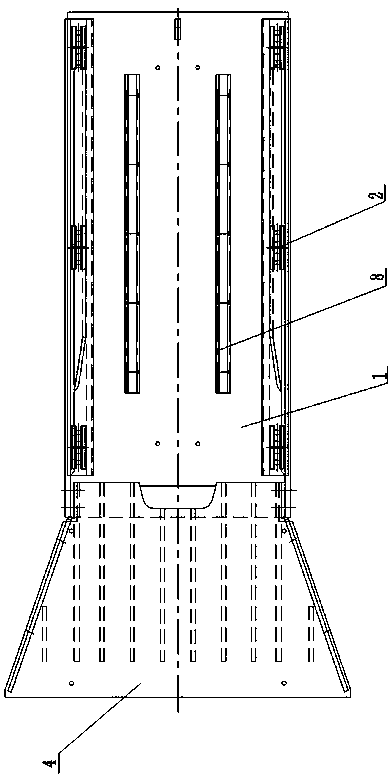

[0020] See the accompanying drawings: an X-type truck loading machine for underground large parts for mining, consisting of a base 1, a support platform 5 and a transport flat car 7, a lifting mechanism is installed between the base 1 and the support platform 5, and the front end of the base 1 is connected by The shaft 6 is connected with the box-shaped inclined plane body 4; the base 1 is provided with three sets of lifting mechanisms, and each set of lifting mechanisms is composed of lifting units 2 symmetrically arranged on both sides of the base 1, and the lifting units 2 are composed of connecting rod a201, connecting rod b202, hydraulic pressure Composed of cylinder a203 and hydraulic cylinder b203, one end of the connecting rod a201 is hinged to the base 1, the other end is hinged to the piston rod of the hydraulic cylinder a203, one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com