Crude oil pipeline conveying and fixing device

A pipeline transportation and fixing device technology, which is applied in pipeline protection, pipeline support, pipeline damage/wear prevention, etc. It can solve the problems that the height of the transportation fixing device cannot be adjusted, the pipeline cannot be adjusted according to the demand, and the service life of the pipeline is reduced. Strong adjustability, easy installation and docking, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

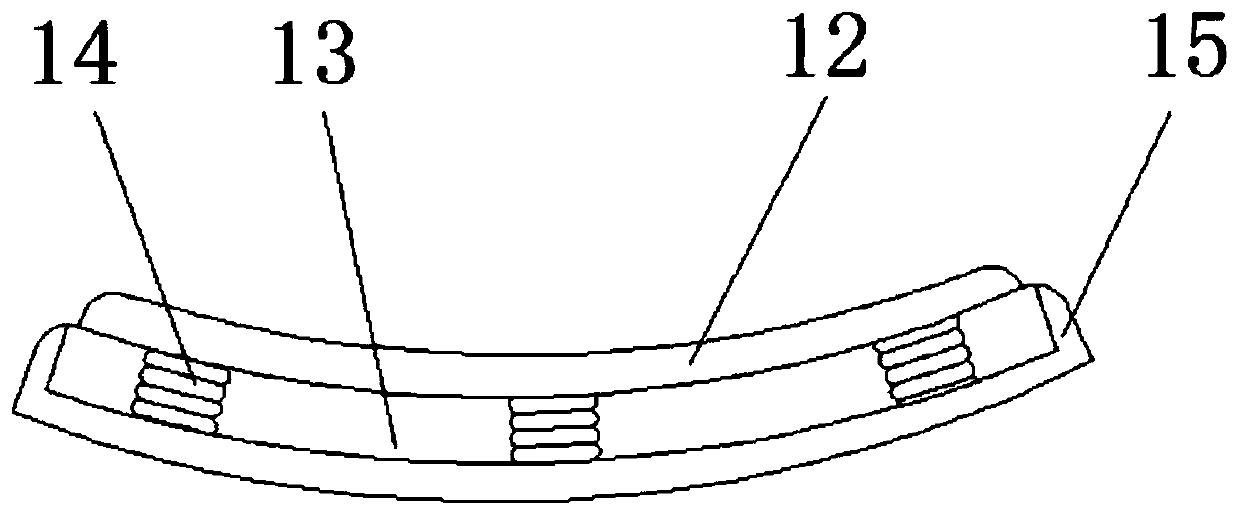

[0023] A fixing device for crude oil pipeline transportation, comprising a base 3 and a first fixing block 1, the first fixing block 1 is installed on one side of the top of the base 3, and a coil 6 is installed on the side of the top of the base 3 away from the first fixing block 1 , the base 3 between the first fixed block 1 and the coil 6 is provided with a chute 2, the chute 2 is installed with a second fixed block 4 through the slider, and the second fixed block 4 is away from the side of the first fixed block 1 Bearing 9 is installed, and connecting rod 5 is installed in the inside of bearing 9, and threaded rod 7 is installed on the internal thread of spiral tube 6, and threaded rod 7 is connected with connecting rod 5, and the top of second fixed block 4 is hinged with first support rod 10 , and the end of the first support rod 10 away from the second fixed block 4 is hinged with a connecting seat 27, the top of the first fixed block 1 is hinged with a second support ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com