Injecting moving device for concrete prefabricated wall panel

A prefabricated wall panel and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problem of consuming a lot of manpower to carry concrete prefabricated wall panels, etc., and achieve the effect of saving manpower and stabilizing the support frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

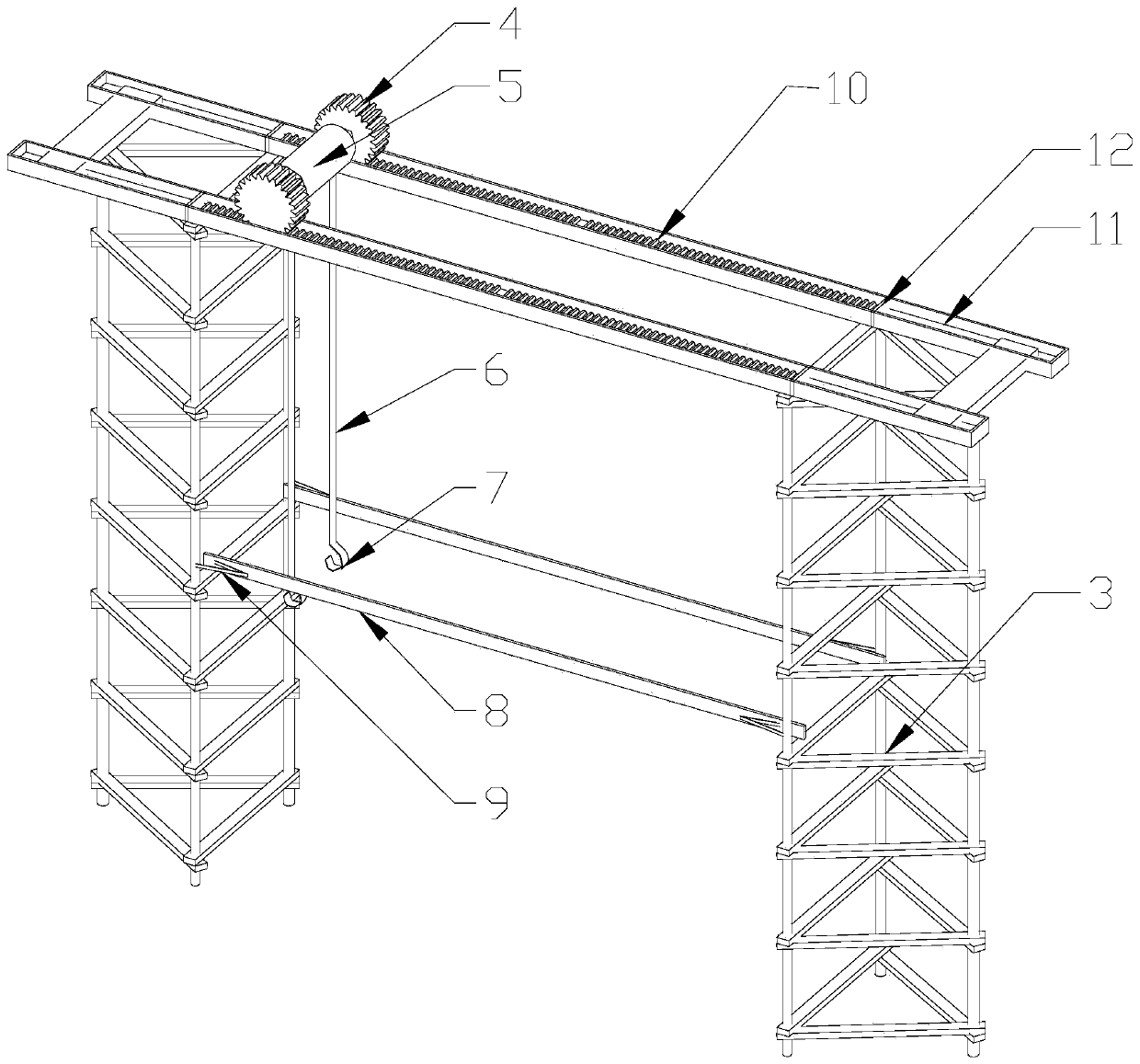

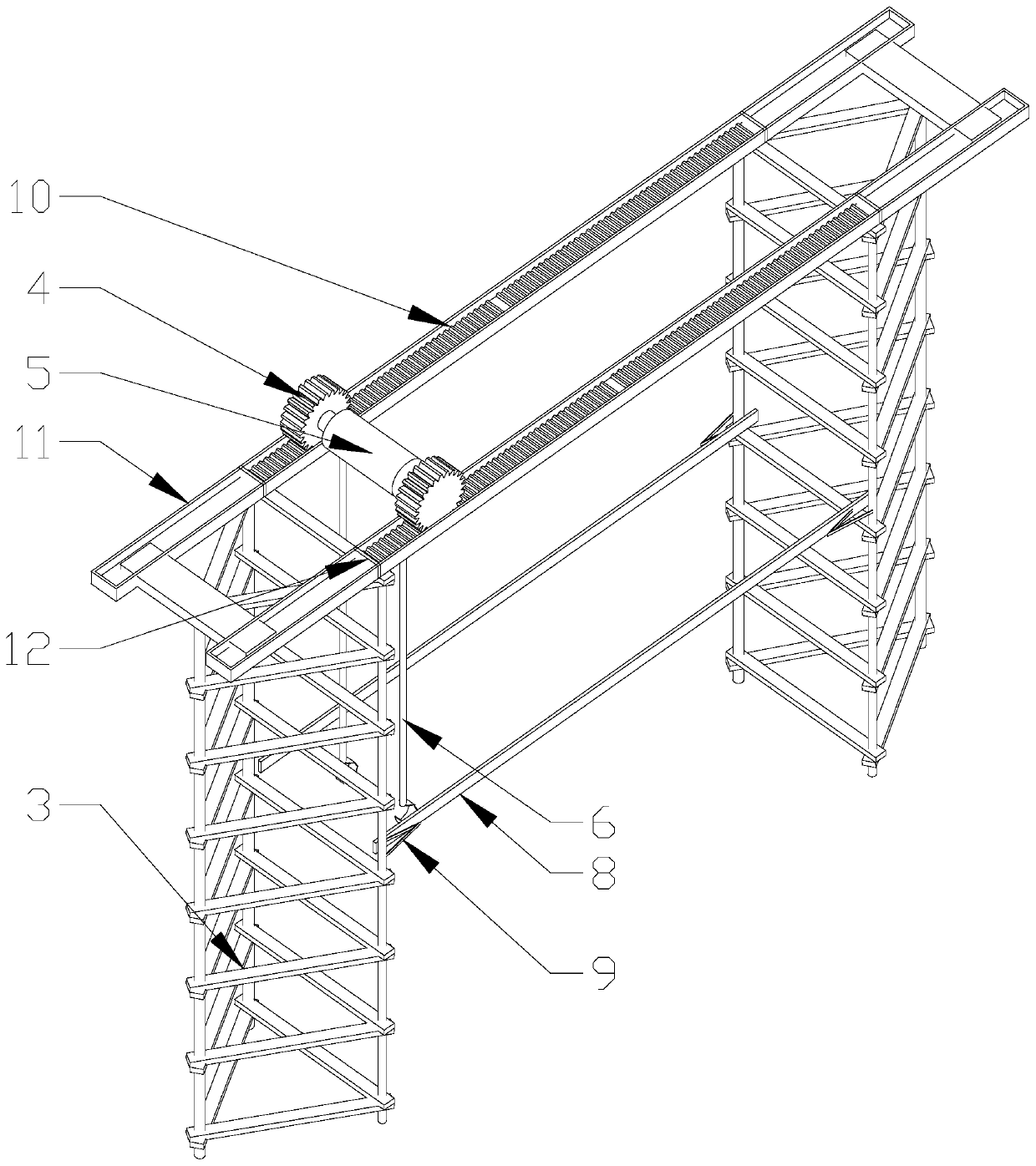

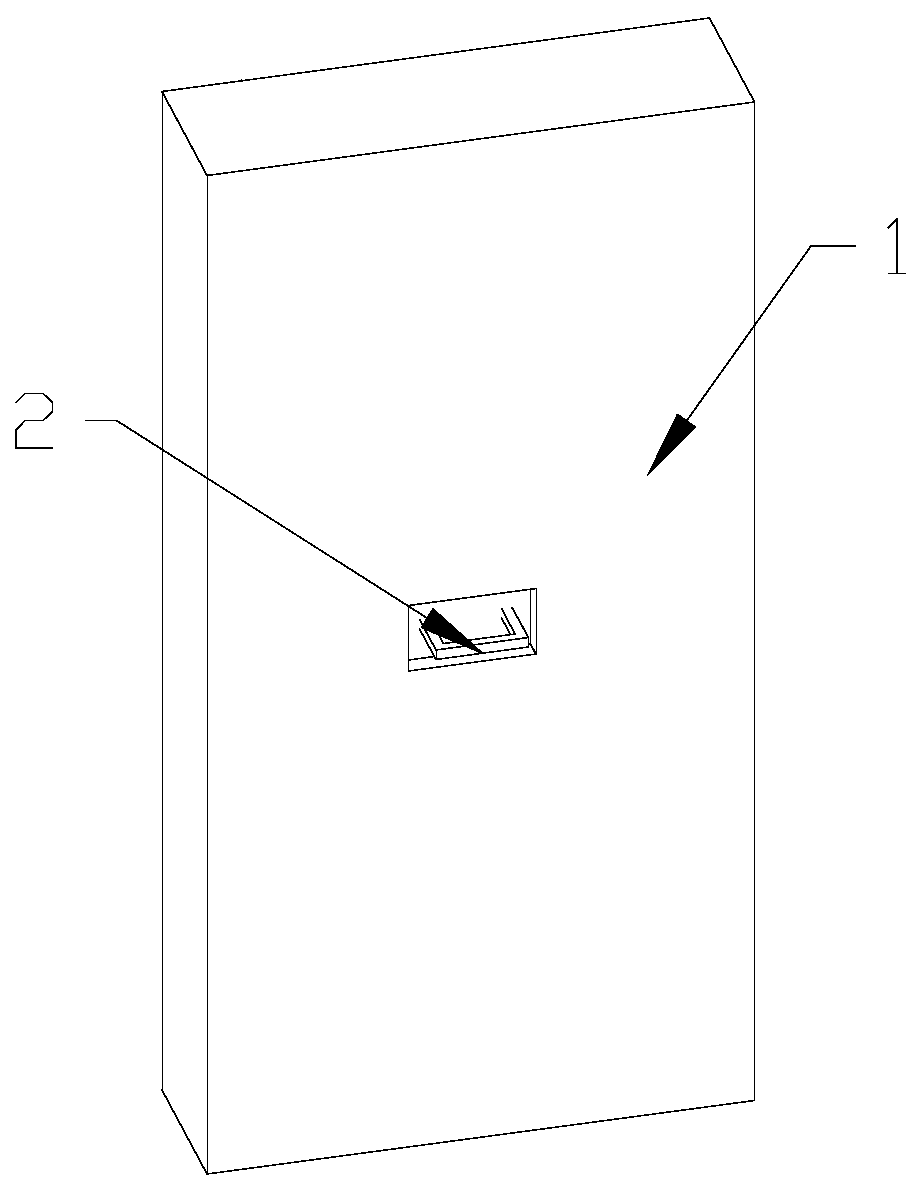

[0024] Embodiment: a kind of jacking device of concrete prefabricated wall panel 1, as Figure 1-3 As shown, it includes a detachable hook 2 arranged on the concrete prefabricated wall panel 1, a support frame 3, a track device connected to the upper end of the support frame 3, a wheel device 4, a motor unit 5 connected to the wheel device 4, and a motor unit 5 The rope 6 that the lower end is connected, the hook 7 that is connected with the lower end of the rope 6, the switch that is used to control the start and close of the motor unit 5 and the power supply that is connected with the motor unit 5, the hook 2 and the concrete prefabricated wall panel 1 can be connected by screws, and can be used in A groove is set on the prefabricated concrete wall panel 1, and the connection between the hook 2 and the prefabricated concrete wall panel 1 is in the groove. Take it off from the prefabricated concrete wall panel 1, fill the groove on the prefabricated concrete wall panel 1 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com