Straw filament rubbing and compacting field returning machine

A technology of straw and silk rollers, which is applied in the field of straw rubbing and densification returning machines, can solve the problems of insignificant organic matter content, inability of seeds to be in close contact with the soil, and slow decomposition of straw, so as to improve economic efficiency and long-term Sustainability of returning to the field, decomposition speed and nutrient release, and the effect of improving the distribution of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

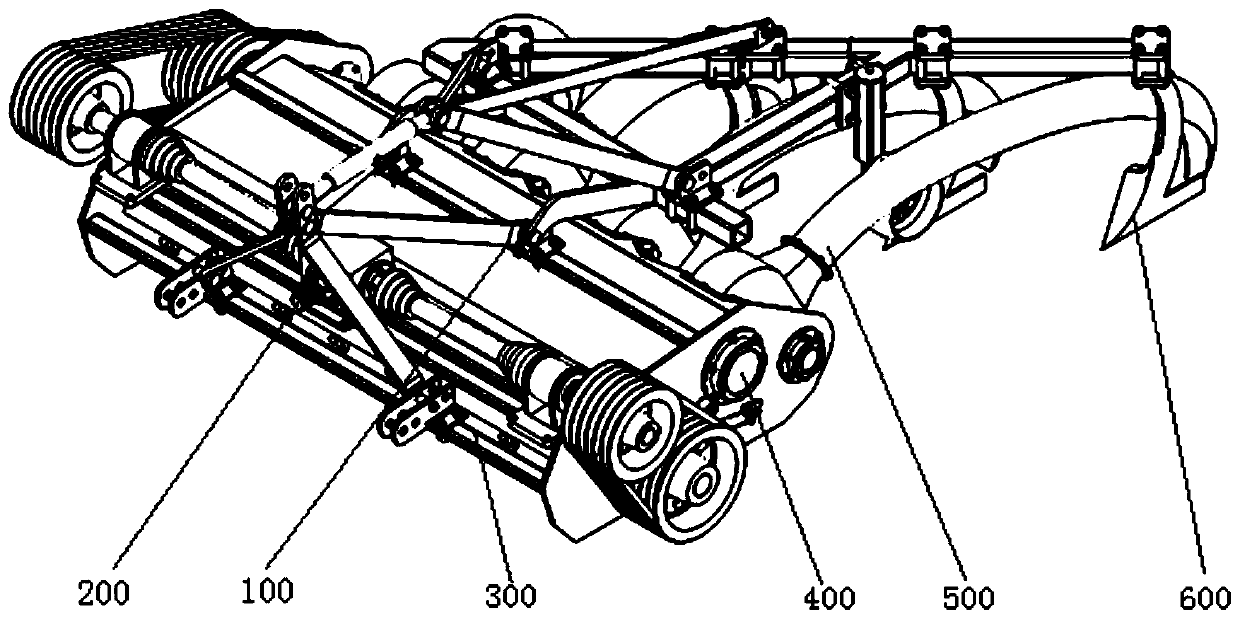

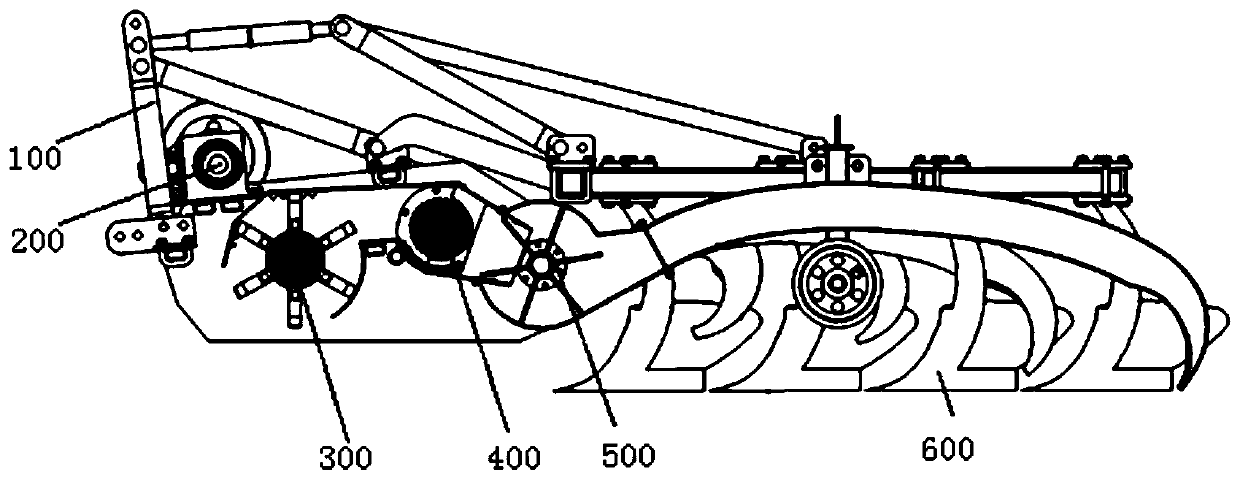

[0070] Such as Figure 1-2 As shown, the present invention provides a straw kneading and densifying returning machine, which mainly includes: a straw kneading and densifying machine housing 100, a power transmission device 200, a picking and shredding device 300, and a kneading and thinning device 400. Throwing and lifting conveying device 500, earth-digging and burying densification device 600.

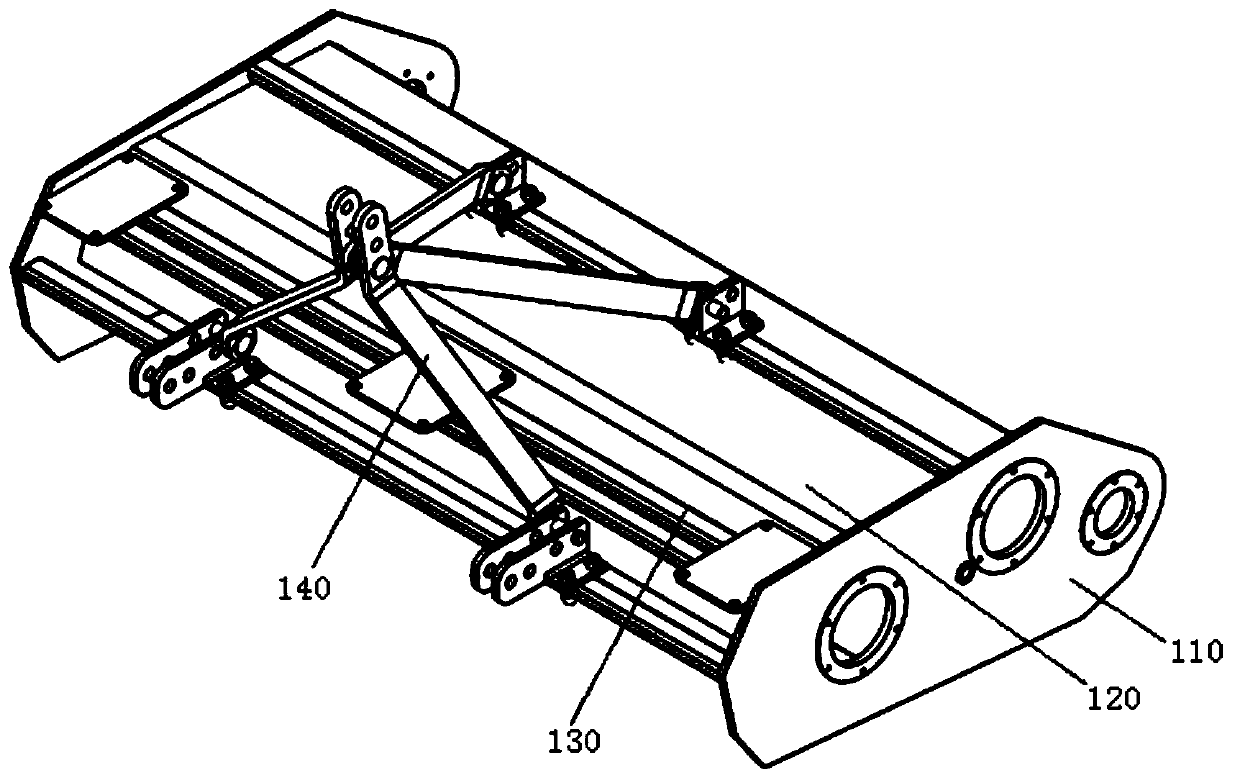

[0071] Such as image 3 As shown, the casing 100 of the straw rubbing and densifying machine includes: a side plate 110 , a steel plate 120 , a beam 130 , and a three-point suspension rod 140 . The casing 100 of the straw kneading and silk-densifying machine is welded by two side plates 120, plate-shaped steel 120 and beam 130, and the three-point suspension rod 140 is hinged to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com