Functionalized graphene oxide/poly(3,4-ethylenedioxythiophene) composite material and preparation method thereof

A technology of ethylenedioxythiophene and composite materials, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of interface recombination, poor cycle stability, poor specific capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of functionalized graphene oxide GO-TAA

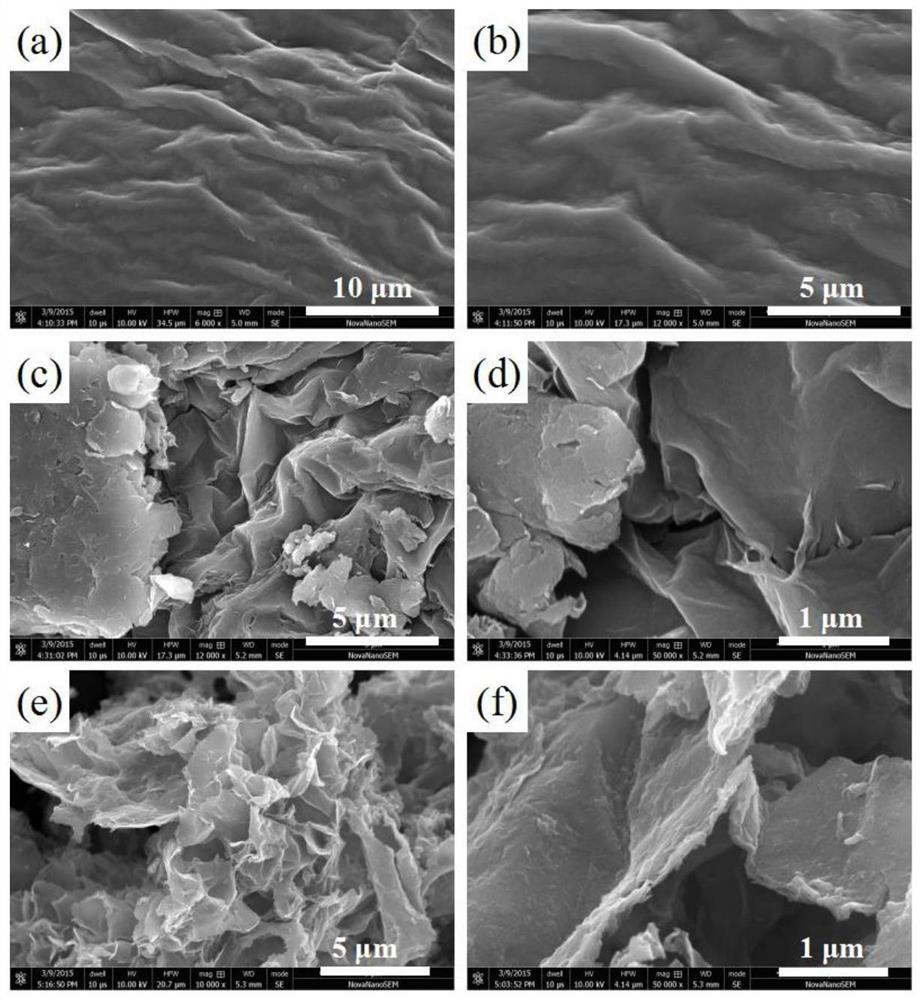

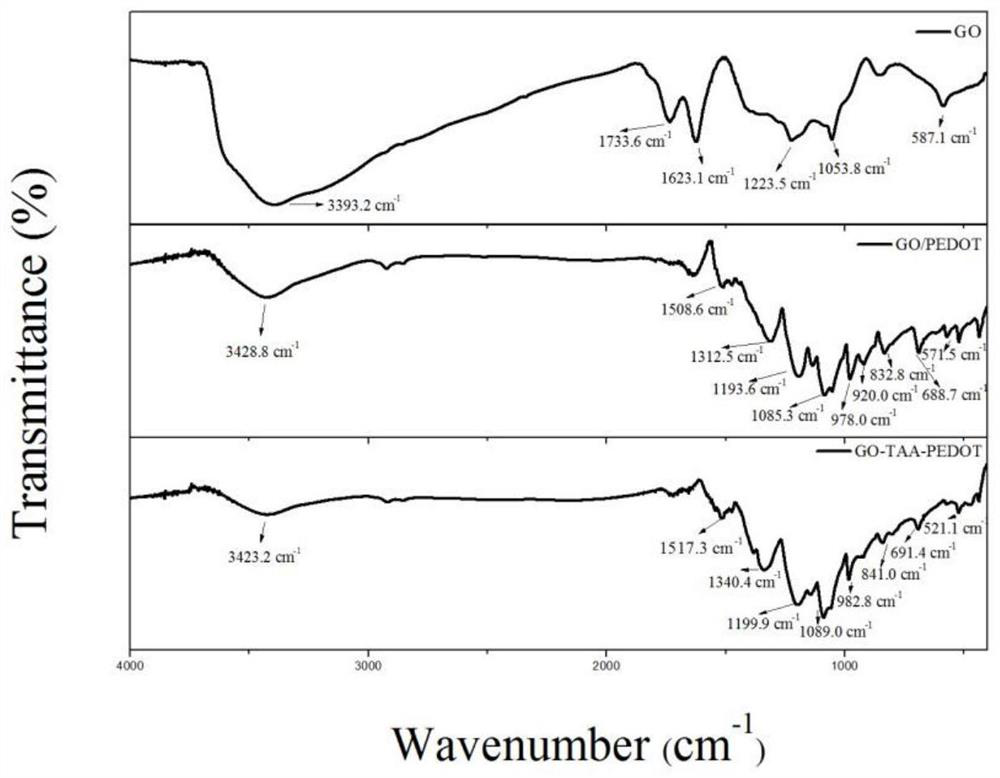

[0034] Weigh 0.1g of graphene oxide (GO) and 1.05g of 2-thiopheneacetic acid into a 250mL round bottom flask, add 100mL of anhydrous dimethyl sulfoxide (DMSO) and ultrasonically shake for 1h, then add 0.1g of p-toluene Sulfonamide. Bubble nitrogen at a large flow rate for 10 minutes, then heat to 150°C and stir the reaction under continuous bubbling. The water produced by the esterification reaction will be separated from DMSO in the form of an azeotrope until no new one is formed in the water separator. Liquid, the reaction stopped, the reaction 7.5h. The reacted mixture was washed with methanol by centrifugation to remove unreacted 2-thiopheneacetic acid. Finally, the product was vacuum-dried at 60°C for 24 hours to obtain functionalized graphene oxide, which was named GO-TAA. For its scanning electron micrograph, see figure 1 In (a) and (b), the infrared spectrogram see figure 2 .

[0035] (2) Preparatio...

Embodiment 2

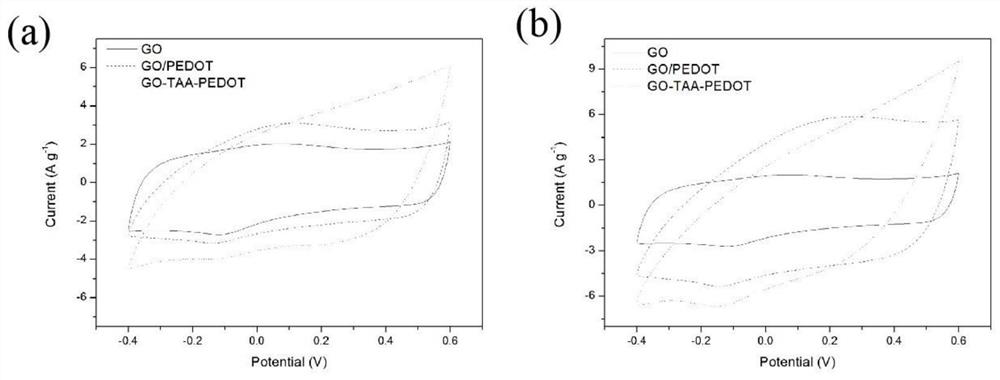

[0041] Electrochemical performance test:

[0042] (1) Electrochemical performance test of composite GO-TAA-PEDOT

[0043] Preparation of working electrode: Mix and stir GO-TAA-PEDOT, acetylene black (conductive agent) and polytetrafluoroethylene (binder) in a mass ratio of 8:1:1 to make it a good ductile of mixed materials. Then use a pestle to press and roll it into a sheet-like material with a thickness of about 200 μm, and dry it in a vacuum oven at 60° C. for 24 hours before use. During the test, it is pressed against the platinum sheet with a pressure of 20MPa.

[0044] (2) Electrochemical performance test of composite GO / PEDOT

[0045] Preparation of the working electrode: GO / PEDOT, acetylene black (conductive agent) and polytetrafluoroethylene (binder) were mixed and stirred at a mass ratio of 8:1:1 to make it a mixture with good ductility Material. Then use a pestle to press and roll it into a sheet-like material with a thickness of about 200 μm, and dry it in a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com