A method for predicting the porosity of carbonate rocks and a method for constructing a prediction model

A carbonate rock and prediction model technology, which is used in the field of petroleum and mining to predict the porosity of carbonate rocks indoors, and the geological field. , the experimental steps are simple, and the prediction reliability is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

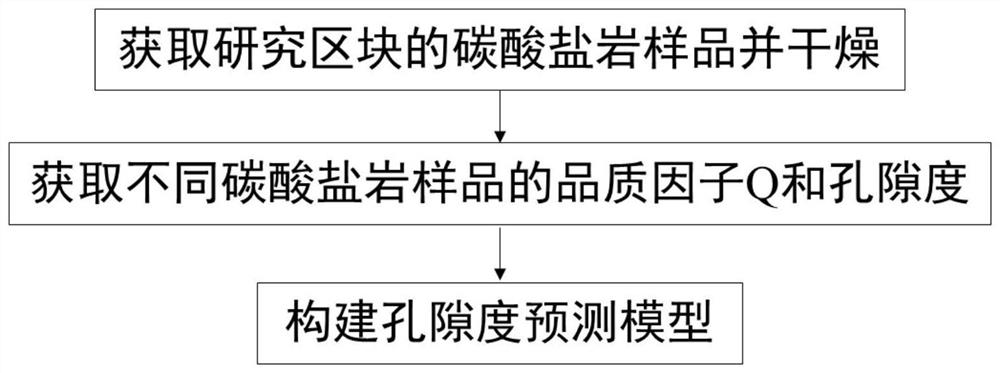

[0027] like figure 1 A method for constructing a carbonate rock porosity prediction model is shown, including the following steps:

[0028] A. Obtain carbonate rock samples from the research block and dry them;

[0029] B. Obtain the quality factor Q and porosity of different carbonate rock samples;

[0030] C. According to the quality factor Q and porosity of different carbonate rock samples, a prediction model of porosity is constructed.

[0031] The quality factor Q here can be obtained by various methods, for example, measured by a helium porosimeter, or obtained by experimental calculation. The specific method obtained by experimental calculation is: obtain the core acoustic wave waveform, calculate the quality factor Q of different carbonate rock samples, and the calculation method is as follows:

[0032]

[0033] Among them, E 0 , E x are the initial energy and the energy after propagation x distance, respectively, λ is the wavelength of the dominant frequency, ...

Embodiment 2

[0041] This embodiment refines the foregoing method on the basis of the principle of the foregoing embodiment.

[0042] The method is suitable for carbonate rock samples of different shapes and sizes, and a method for constructing a carbonate rock porosity prediction model includes the following steps:

[0043] A. Drill the rock sample from the outcrop rock sample. During the drilling process, ensure that the non-parallelism of the two end faces of the core does not exceed 0.05mm, and the maximum deviation of the end face of the core and the plane perpendicular to the axis of the specimen does not exceed 0.25°. It is required to make core samples such as Figures 2 to 4 shown. Put rock samples of different shapes in an oven to bake for 24 hours, then measure and record their quality with a precision balance, and then dry them for 1 hour and measure the quality. If there is no significant change in quality, put the rock samples in a sealed bag If there is a significant change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com