Annular connecting device for connecting of all-casing drilling occlusive piles and structural bottom plate steel bars

A technology of drilling occlusal piles and annular connection, which is used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of narrow space at the joint, high manufacturing cost, unstable structure, etc., to achieve convenient operation and reduce work difficulty. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

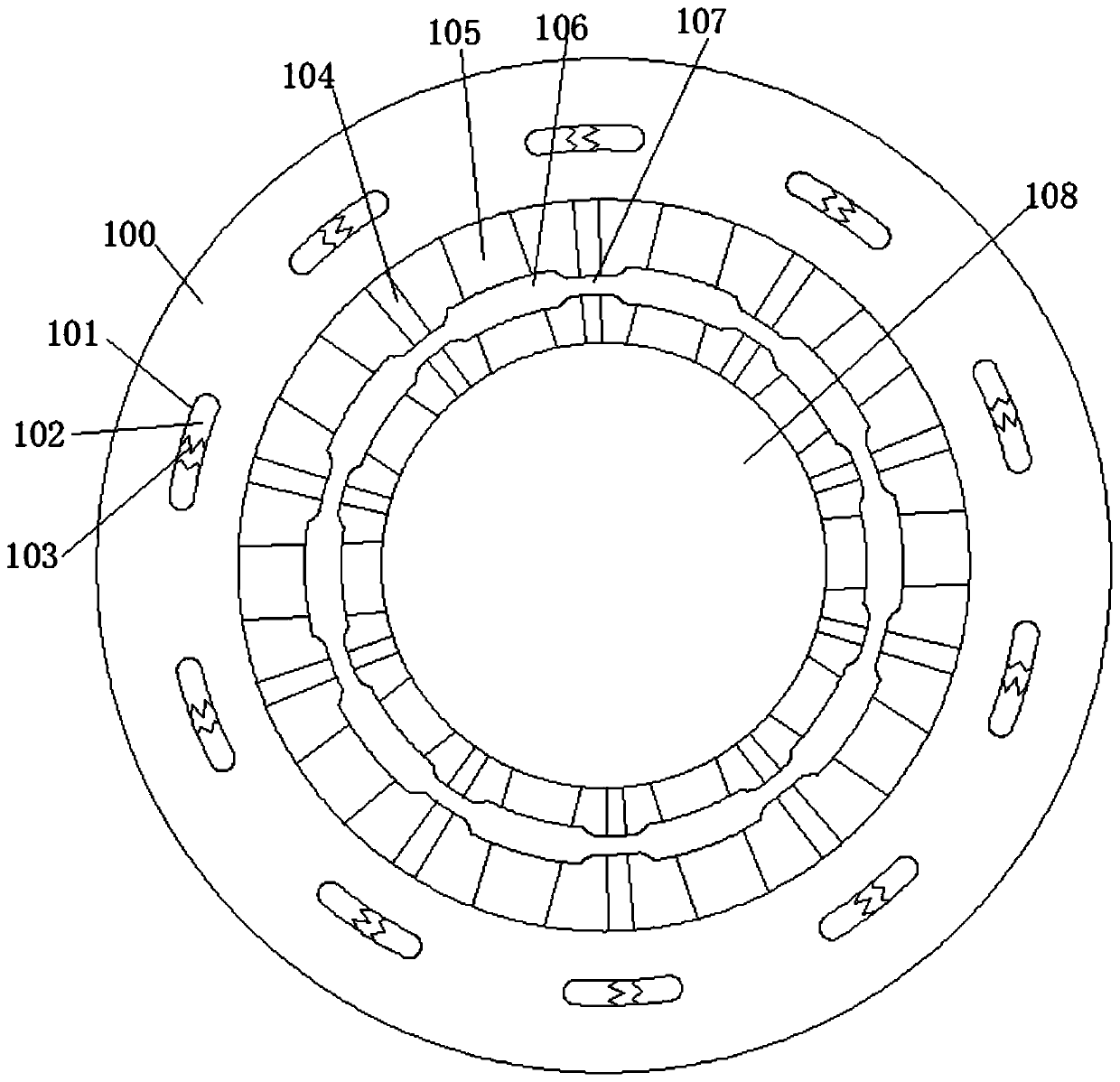

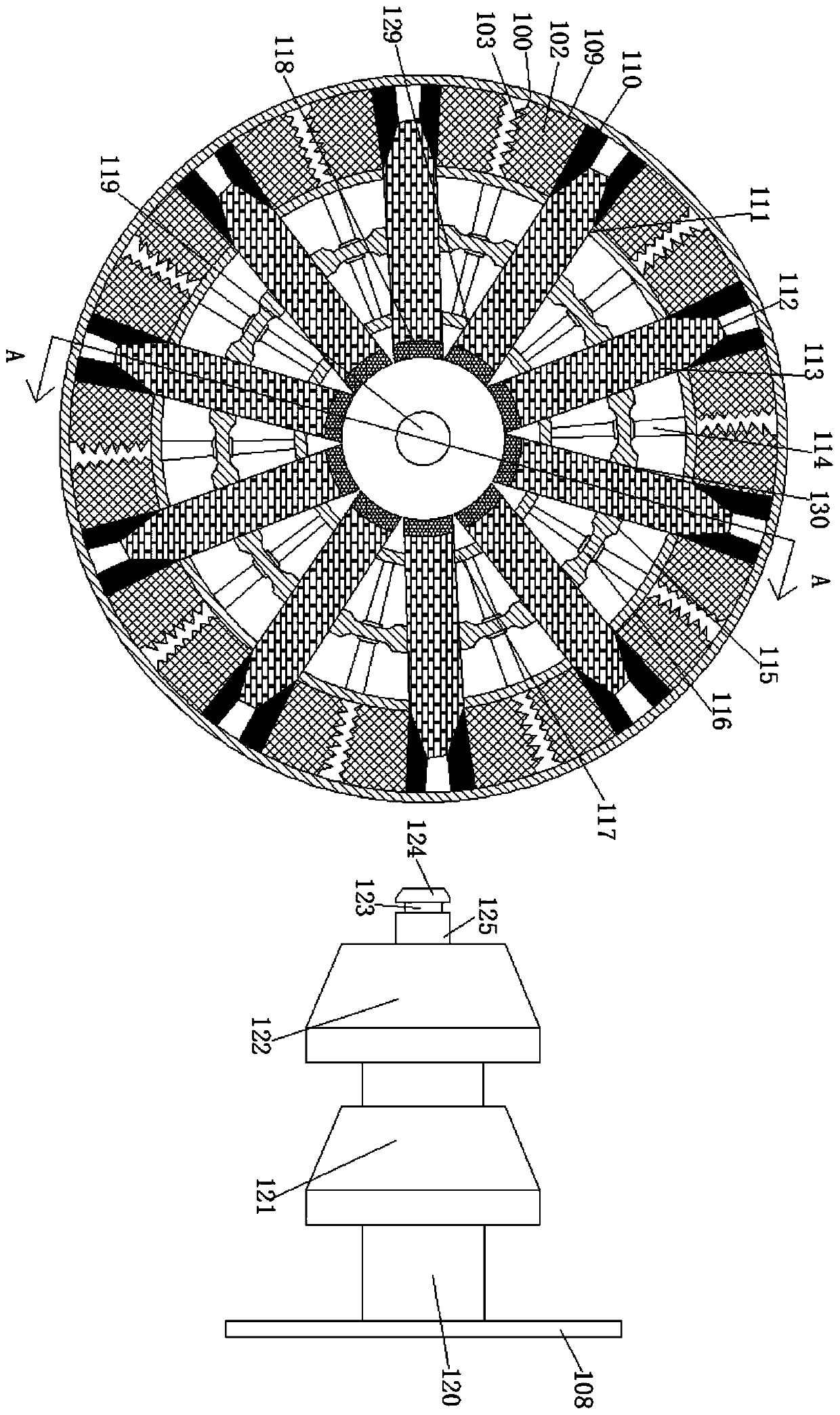

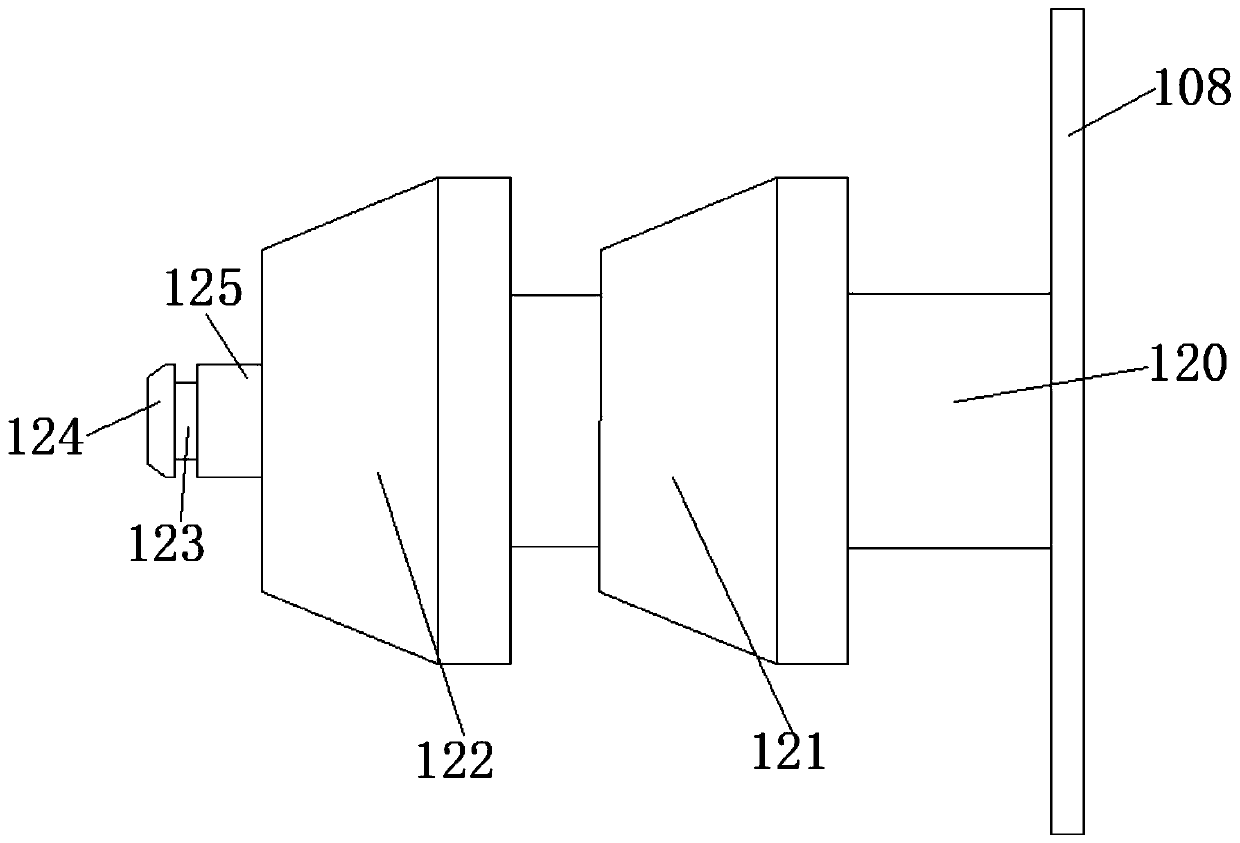

[0022] see figure 2 and Figure 4 , an annular connection device for connecting full-sleeve drilled occlusal piles to structural floor steel bars, which includes an annular shell 100, an annular cavity 109 is provided in the annular shell 100, and the annular cavity 109 runs through the annular shell 100 There are a plurality of docking holes 101 distributed in the circumferential direction, and the inner wall of the inner ring of the annular housing 100 is provided with a double-layered first slot 111 between any two adjacent docking holes 101. The shell 117 at the center of the shell 100 opens upwards, and the inner wall of the side of the shell 117 is provided with a second slot 129 corresponding to the first slot 111 one by one, and the side of the shell 117 is located adjacent to another second slot Between the end face between 129 and the inner wall of the annular shell 100 between the side surfaces between the adjacent first slots 111, there are fixedly connected doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com